Precision Aluminum CNC: Avoid Common Mistakes

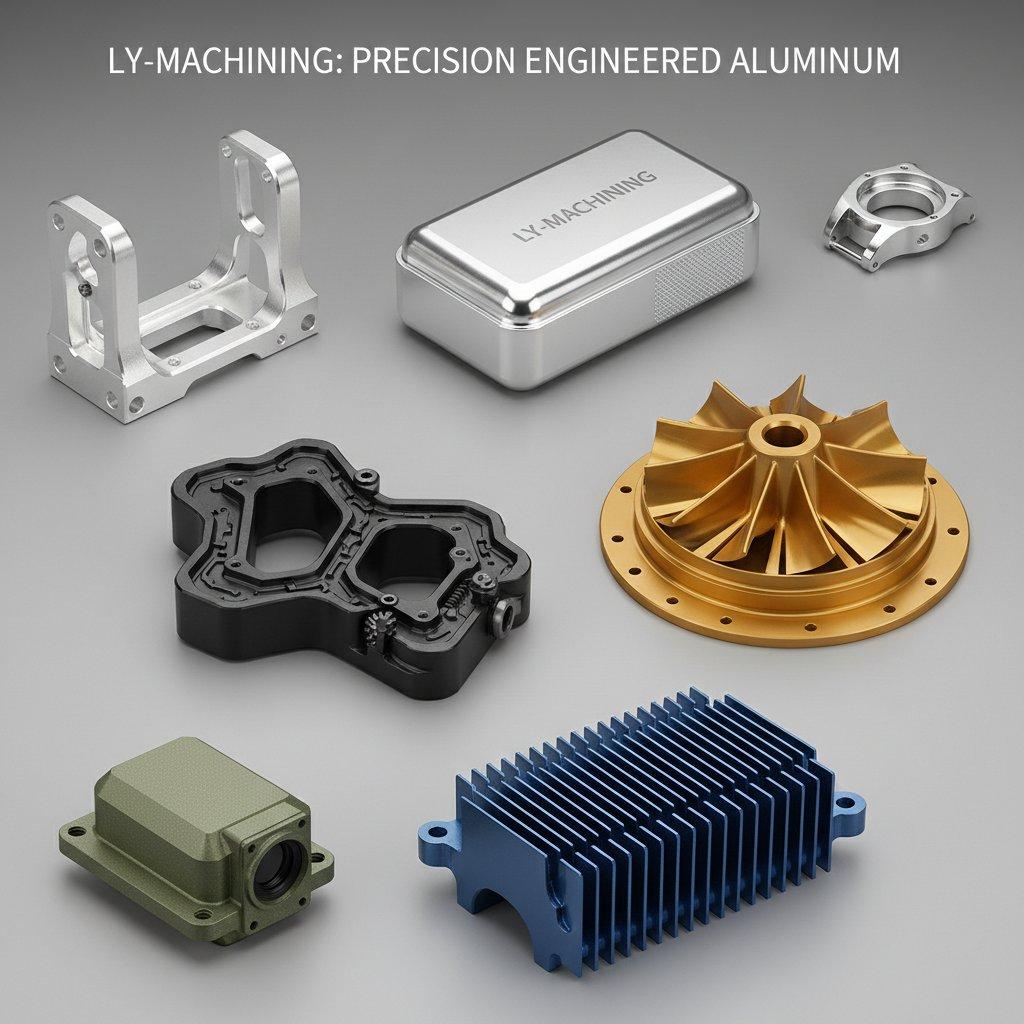

Precision Aluminum CNC Machining requires meticulous attention to detail to achieve high-quality aluminum parts. Overcoming common aluminum machining errors through robust CNC machining best practices is crucial for manufacturing excellence.

Are seemingly minor precision aluminum machining mistakes silently sabotaging your project budgets and timelines? In high-stakes industries, even tiny imperfections can lead to significant failures and costly delays. The pursuit of high-quality aluminum parts often reveals hidden challenges.

Yet, these pervasive aluminum machining errors are not inevitable. With a deep understanding of the intricacies of precision aluminum CNC machining, they are entirely preventable. This guide will illuminate the common pitfalls and detail the CNC machining best practices that ensure flawless outcomes, transforming your design concepts into reality.

Design Flaws & Precision Aluminum Pitfalls

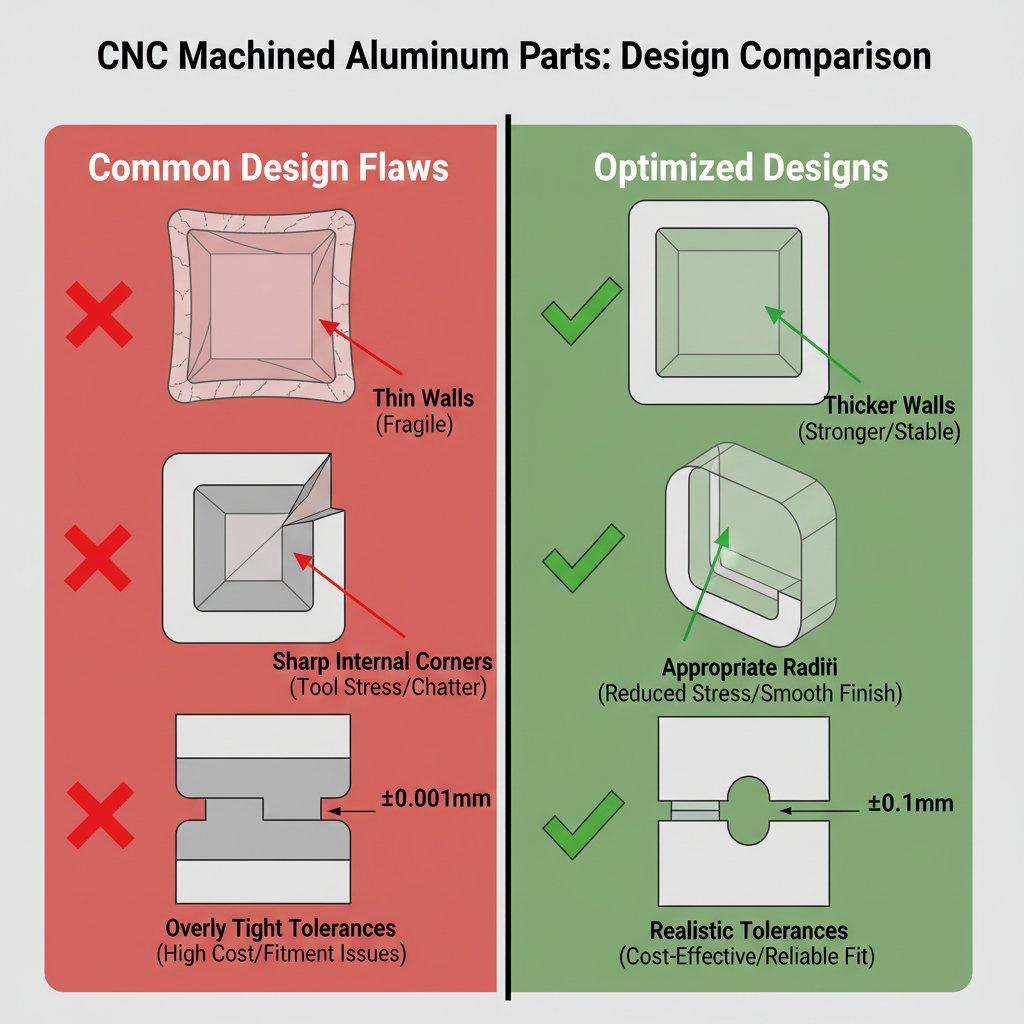

In our experience, many aluminum machining errors originate not on the shop floor, but at the design stage. Overlooking manufacturability can lead to significant issues during precision aluminum CNC machining. Addressing these early prevents costly rework.

Unrealistic Tolerance Specifications

Specifying tolerances tighter than functionally necessary is a common pitfall. Ultra-tight tolerances drastically increase machining time, tooling wear, and inspection costs. They often push beyond the practical limits of standard CNC machining best practices.

It’s essential to balance design intent with manufacturing capability. Collaborating with your machining partner on Design for Manufacturability (DFM) reviews can optimize these specifications. This ensures high-quality aluminum parts without excessive cost.

Here’s a general guideline for achievable tolerances based on part size and complexity:

| Feature Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Ultra-Precision Tolerance (mm) |

|---|---|---|---|

| Linear Dimensions | ±0.05 – ±0.1 | ±0.02 – ±0.05 | < ±0.01 |

| Hole Diameter | ±0.025 – ±0.05 | ±0.01 – ±0.025 | < ±0.005 |

| Positional (True Pos) | ±0.1 – ±0.2 | ±0.05 – ±0.1 | < ±0.02 |

| Flatness/Perpendicularity | 0.05 per 100mm | 0.02 per 100mm | < 0.01 per 100mm |

Overlooking Minimum Wall Thickness

Aluminum is highly machinable but requires careful consideration of wall thickness. Thin walls are prone to vibration, distortion, and chatter during cutting, leading to poor surface finish and dimensional inaccuracies. This is a frequent cause of aluminum machining errors.

A general rule for precision aluminum CNC machining is to maintain a minimum wall thickness relative to the part’s overall size and feature depth. Deeper features require proportionally thicker walls for stability. Compromising this can severely degrade high-quality aluminum parts.

Improper Feature Radii & Drafts

Sharp internal corners (zero radius) are impossible to achieve with standard milling tools. Small radii necessitate smaller, more fragile tools, increasing machining time and risk of breakage. This affects the cost and feasibility of high-quality aluminum parts.

Integrating appropriate radii and drafts from the outset is a key CNC machining best practice. This facilitates smoother tool paths and reduces stress concentrations. Optimal design ensures both functionality and manufacturability for precision aluminum components.

Ignoring Surface Finish Requirements

Designers sometimes specify overly stringent surface finishes without considering the cost implications. Achieving very fine finishes, especially on complex geometries, requires additional machining passes, specialized tooling, and potentially post-processing steps.

It’s crucial to specify the required surface finish (e.g., Ra value) based on functional needs, not just aesthetics. Understanding the capabilities of precision aluminum CNC machining for various finishes helps optimize production. This avoids unnecessary costs while still achieving high-quality aluminum parts.

Material Choices in Aluminum Machining Errors

The choice and handling of aluminum material profoundly impact the success of precision aluminum CNC machining. Poor material selection often leads to preventable aluminum machining errors, compromising the integrity of high-quality aluminum parts.

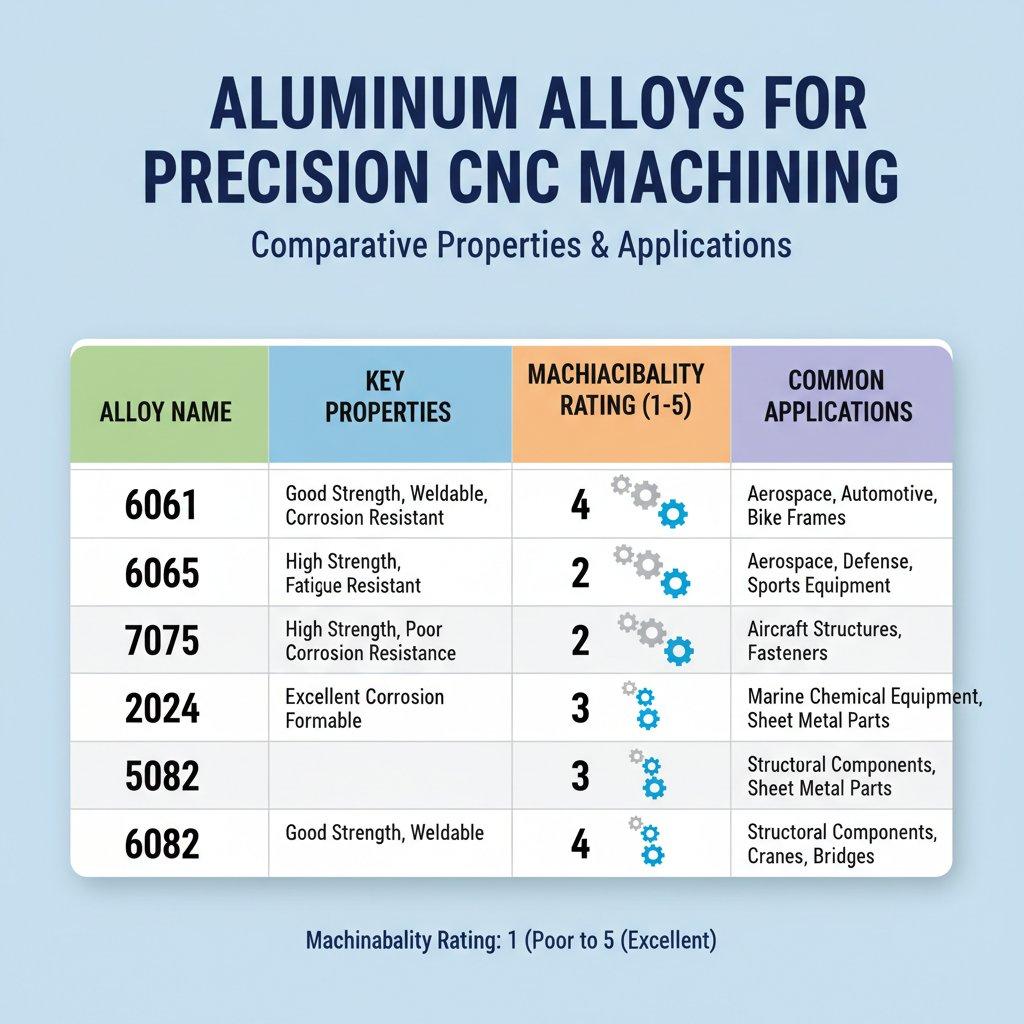

Selecting the Wrong Aluminum Alloy

Not all aluminum alloys are created equal for machining. Some alloys, like 6061, are highly versatile and widely used due to their good machinability and strength. Others, like 7075, offer higher strength but can be more challenging to machine.

Choosing an alloy unsuitable for the required precision, surface finish, or stress application is a critical mistake. Understanding the specific properties and machinability of various alloys is fundamental for CNC machining best practices.

Poor Material Handling & Preparation

Aluminum blanks can harbor internal stresses from rolling or extrusion processes. Improper handling, such as inadequate support or excessive clamping pressure, can introduce or exacerbate these stresses. This can lead to warping during or after machining.

Pre-machining stress relief or carefully planned machining strategies (e.g., roughing followed by stress relief and then finish passes) are essential. This prevents deformation and ensures the dimensional stability required for high-quality aluminum parts.

Misunderstanding Aluminum Thermal Properties

Aluminum has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. This property is a common source of aluminum machining errors if not accounted for. Heat generated during cutting can cause the part to grow.

Precise temperature control in the machining environment and effective cooling during cutting are vital. This minimizes thermal distortion, ensuring that the finished part meets stringent specifications after it returns to ambient temperature. Ignoring this is a major oversight in precision aluminum CNC machining.

Common CNC Machining Process Mistakes

Even with perfect design and material, the machining process itself can introduce significant aluminum machining errors. Implementing stringent CNC machining best practices is paramount to consistently produce high-quality aluminum parts.

Incorrect Cutting Parameters & Speeds

Using incorrect feed rates, spindle speeds, or depth of cut can lead to various problems. These include poor surface finish, excessive tool wear, chip welding, and even tool breakage. Each alloy requires specific parameters for optimal results in precision aluminum CNC machining.

In our factory, we develop and fine-tune our cutting parameters through extensive testing and experience. This ensures efficient material removal while maintaining precision and extending tool life. This systematic approach minimizes common aluminum machining errors.

Ineffective Chip Management Strategies

Aluminum produces long, stringy chips that can wrap around the tool, scratch the part surface, or even clog the machine. Poor chip evacuation can lead to heat buildup, recutting of chips, and surface defects. This compromises high-quality aluminum parts.

Effective chip management involves optimized tool paths, high-pressure coolant, and proper chip breaking techniques. Our advanced machines feature integrated chip conveyors and sophisticated coolant systems. These are essential CNC machining best practices for aluminum.

Inadequate Cooling & Lubrication

Heat generated during cutting can lead to thermal expansion, affecting dimensional accuracy. Insufficient lubrication can increase friction, leading to higher temperatures and accelerated tool wear. These are critical aluminum machining errors.

We utilize advanced cooling techniques, including through-spindle coolant and high-volume flood coolants, precisely directed at the cutting zone. This ensures consistent part temperature and effective chip evacuation. This is fundamental for precision aluminum CNC machining.

Suboptimal Tool Path Generation

Inefficient or poorly planned tool paths can cause abrupt changes in cutting forces, leading to chatter, tool deflection, and poor surface finish. This is a common source of dimensional inaccuracies and reduced tool life. Generating optimized paths is a core CNC machining best practice.

Our engineers use advanced CAM software to simulate and optimize tool paths, considering material properties, tool geometry, and machine kinematics. This minimizes tool engagement variations and ensures smooth, consistent cutting, producing high-quality aluminum parts.

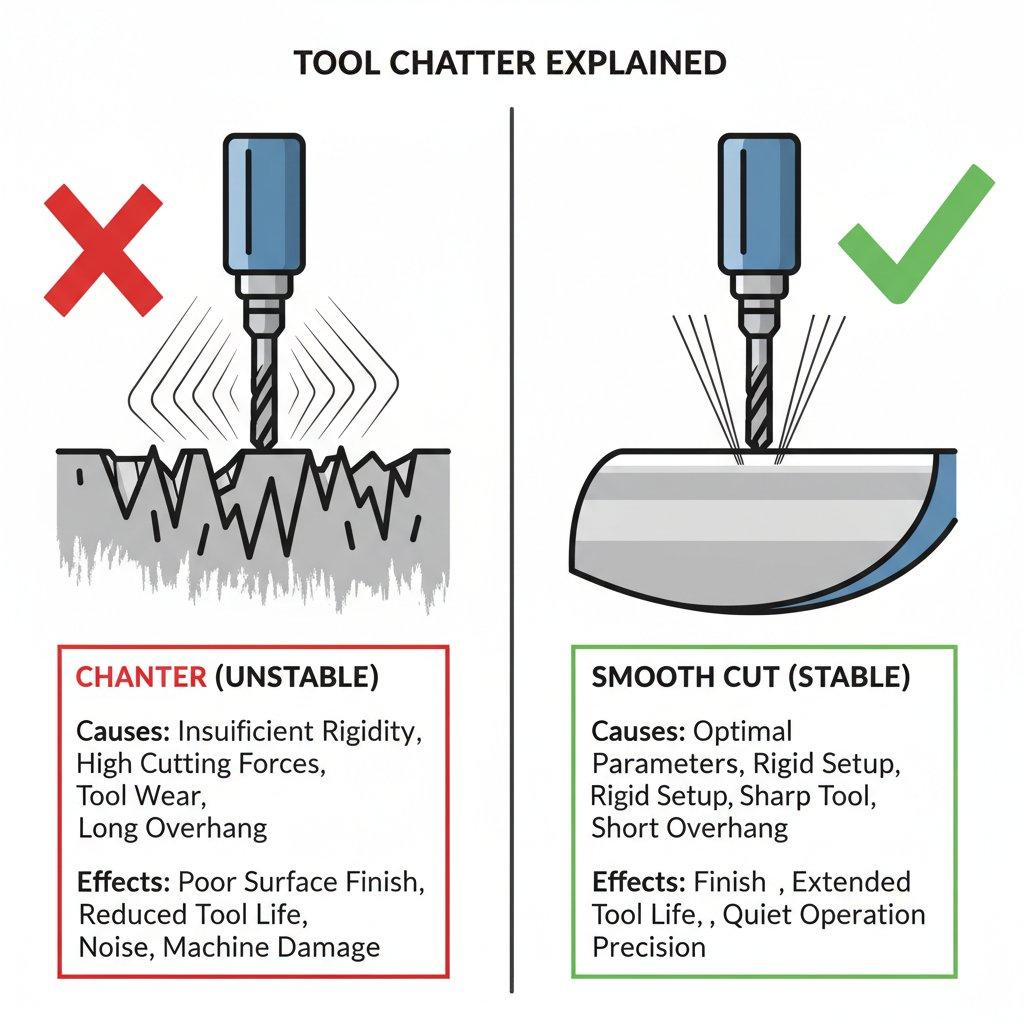

Vibration & Chatter in Aluminum Machining

Chatter is a self-excited vibration that leaves visible marks (chatter marks) on the part surface and significantly reduces tool life. It often results from insufficient machine rigidity, tool overhang, or improper cutting parameters. This is a pervasive cause of aluminum machining errors.

Addressing chatter requires a holistic approach: ensuring machine and fixture rigidity, selecting appropriate tools, and optimizing cutting parameters. In our facility, we employ dynamic analysis and vibration damping techniques to mitigate chatter.

Tooling & Fixturing Errors for Precision

The right tools and a robust fixturing setup are non-negotiable for precision aluminum CNC machining. Mistakes in these areas are frequent causes of aluminum machining errors and compromised part quality.

Using the Wrong Tool Geometry & Material

Aluminum requires specific tool geometries designed for efficient chip evacuation and minimal burring. Using general-purpose tools, or tools designed for harder materials, can lead to poor surface finish, faster tool wear, and even part deformation.

We meticulously select cutting tools based on the specific aluminum alloy, feature geometry, and desired surface finish. This includes specialized coatings and flute designs optimized for precision aluminum CNC machining.

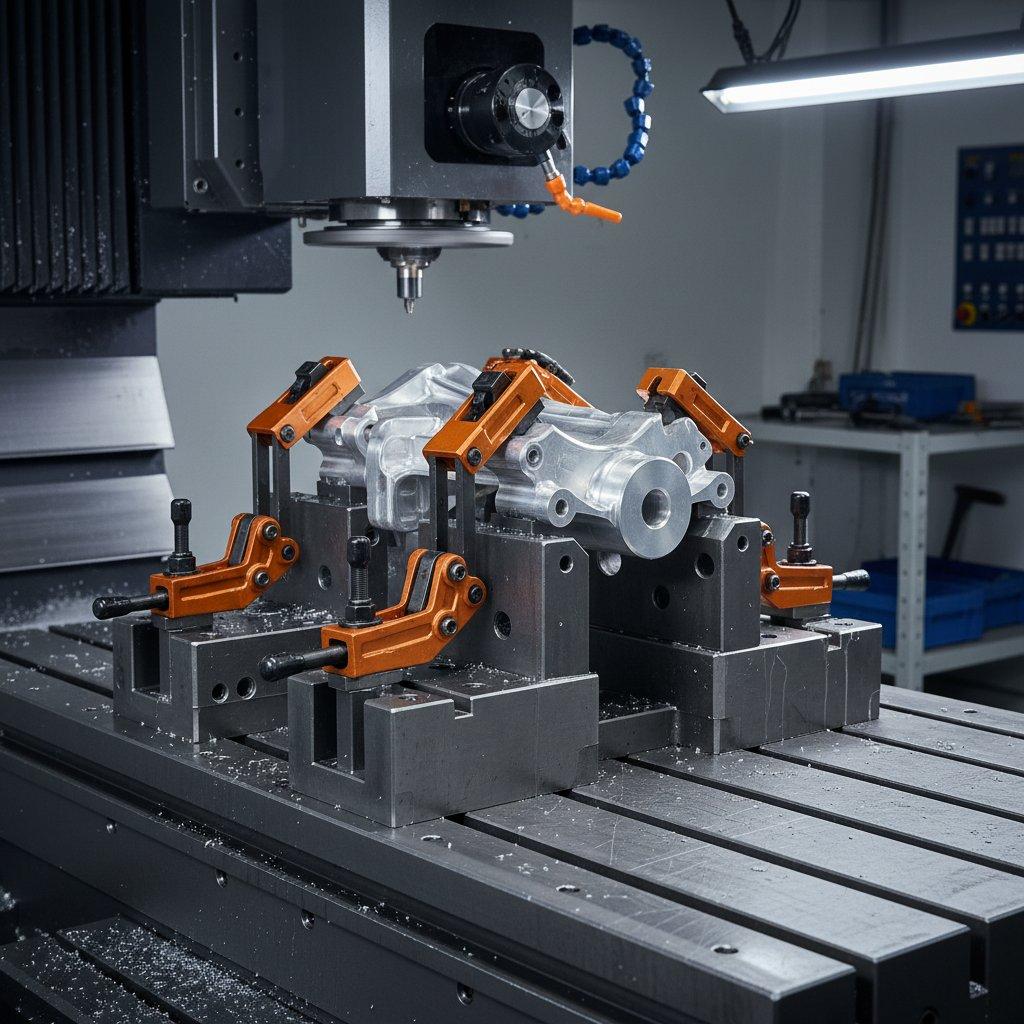

Insufficient Fixture Rigidity & Clamping

An unstable or poorly designed fixture allows the workpiece to vibrate or shift during machining. This directly leads to dimensional inaccuracies, poor surface finish, and can even eject the part, causing significant damage.

Our custom fixturing solutions are designed for maximum rigidity and secure clamping, distributing forces evenly to prevent distortion. This ensures the workpiece remains stable throughout the entire machining process. This is a fundamental CNC machining best practice for high-quality aluminum parts.

Incorrect Tool Life Management

Running tools beyond their optimal life span leads to degraded cutting performance, increased cutting forces, and poor surface finish. Conversely, changing tools too early increases consumable costs unnecessarily. This balance is key to avoiding aluminum machining errors.

We implement sophisticated tool monitoring systems and predictive maintenance schedules. This ensures tools are replaced precisely when needed, optimizing both part quality and operational efficiency in precision aluminum CNC machining.

Quality Control Mistakes in Aluminum Parts

Even after mastering the machining process, quality control oversights can negate all previous efforts. Robust inspection and post-processing are vital CNC machining best practices to deliver high-quality aluminum parts.

Inconsistent Measurement Practices

Varying measurement tools, environmental conditions, or operator techniques can lead to inconsistent readings and false rejections or acceptances. This creates unreliable data and compromises the quality assurance process.

We adhere to strict ISO and AS9100 certified quality management systems. Our climate-controlled inspection labs utilize calibrated CMMs, optical comparators, and other advanced metrology equipment. This ensures consistent and accurate measurement for every precision aluminum CNC machining project.

Neglecting Post-Machining Cleaning

Residual oils, coolants, and microscopic burrs can compromise the part’s functionality or appearance, especially for sensitive applications. Improper cleaning can also hinder subsequent processes like anodizing or painting.

Our comprehensive post-machining cleaning protocols include ultrasonic cleaning, vapor degreasing, and specialized deburring techniques. This ensures every high-quality aluminum part leaves our facility pristine and ready for its intended use.

Skipping Critical Inspection Stages

Relying solely on final inspection is a significant risk. Mistakes caught early in the process are far less costly to correct. Skipping in-process inspections allows defects to propagate, leading to higher scrap rates and project delays.

We implement multi-stage inspection points throughout the precision aluminum CNC machining process. From first-off part inspection to in-process checks and final QC, every stage is meticulously verified. This proactive approach prevents aluminum machining errors from escalating.

Partnering for Flawless Precision Aluminum

Choosing the right partner is paramount to overcoming precision aluminum CNC machining challenges. Our deep expertise and integrated approach guarantee high-quality aluminum parts, consistently exceeding expectations.

Our Deep Technical Expertise in CNC

As a source manufacturer with decades of experience, our team of engineers and machinists possesses unparalleled knowledge in precision aluminum CNC machining. We specialize in complex geometries and ultra-tight tolerances for critical applications. This expertise is a cornerstone of our CNC machining best practices.

We thrive on solving intricate manufacturing problems, offering DFM advice from conception to completion. This proactive engagement eliminates potential aluminum machining errors before they impact production.

Source Manufacturer Advantage & Control

Working directly with a source manufacturer like us means direct communication, complete control over the production process, and greater flexibility. We own every step, from material sourcing to final inspection. This ensures end-to-end quality and accountability.

This integrated approach eliminates common supply chain disconnects and hidden costs. Our transparent processes give you full visibility and confidence that your high-quality aluminum parts are produced with precision and care.

Transparent Quality Assurance Processes

Our commitment to quality is embedded in every stage of our operation, validated by ISO 9001 and AS9100 certifications. We provide comprehensive inspection reports and traceability for all materials and processes. This offers complete peace of mind.

From initial design review to final product validation, our rigorous quality control methodologies are designed to detect and prevent any potential aluminum machining errors. We believe in transparency and verifiable results.

Maximizing Value by Preventing Mistakes

By proactively addressing potential aluminum machining errors, we save our clients significant time and money. Our CNC machining best practices reduce scrap, minimize rework, and accelerate time-to-market for high-quality aluminum parts.

Our value proposition isn’t just about machining; it’s about delivering predictable success and reliability. We are your partner in achieving the highest standards in precision aluminum CNC machining.

Eliminate Your Aluminum Machining Risks

Don’t let common aluminum machining errors jeopardize your next project. Partner with an expert in precision aluminum CNC machining to ensure your designs are realized with unmatched accuracy and reliability.

Your Path to Superior Precision Parts

Leverage our deep technical expertise and proven CNC machining best practices. We are dedicated to delivering high-quality aluminum parts that meet your exact specifications, every time.

Contact Our Engineers for a Quote

Ready to eliminate common precision aluminum machining risks and guarantee superior quality for your next project? Contact our expert engineers today for a free DFM consultation and transparent quote.

Case Study: Optimizing a Robotic Arm Component

A client in the robotics industry approached us with a challenging design for a lightweight robotic arm joint. The original design, when prototyped elsewhere, suffered from significant thermal distortion during machining, leading to unacceptable concentricity errors and inconsistent surface finish. This was a classic aluminum machining error caused by misunderstanding material thermal properties.

Our solution involved a multi-pronged approach. We recommended a specific 7075 aluminum alloy variant known for better stability, combined with an optimized tool path strategy that minimized heat generation. We implemented active, through-spindle coolant delivery and designed a specialized fixture with thermal expansion compensation.

The result was a batch of robotic arm joints that met all tight geometric tolerances, achieved the required smooth surface finish, and showed no signs of thermal distortion. Our expertise transformed a problematic design into a high-quality, reliable component, proving that CNC machining best practices can overcome complex challenges.

Frequently Asked Questions

What causes warping in aluminum parts?

Warping in aluminum parts is primarily caused by internal material stresses exacerbated by improper clamping. Heat generated during cutting also causes thermal expansion. When the part cools unevenly, it contracts disproportionately, leading to deformation.

How can surface finish be improved?

Improving surface finish requires optimized cutting parameters like higher spindle speeds and lower feed rates. Using sharper, specialized tooling with appropriate coatings is also crucial. Effective chip evacuation and coolant application prevent scratching.

What is DFM for aluminum machining?

DFM (Design for Manufacturability) for aluminum machining involves optimizing a product design for ease of manufacturing. This includes considering realistic tolerances, minimum wall thicknesses, and appropriate radii. Collaborating with a manufacturer early prevents costly aluminum machining errors.