Is your high-performance CNC aluminum component underperforming due to inadequate surface protection? Imagine a world where your critical parts withstand extreme wear, harsh corrosion, and intense electrical demands, significantly extending product life and reducing costly failures.

This isn’t a design dream, but a tangible reality that hard anodizing delivers. However, mastering this process requires profound technical expertise and a precise understanding of its intricate parameters.

Discover how to unlock the true potential of your CNC aluminum parts, ensuring they excel in even the most demanding applications with superior performance and unparalleled reliability.

Unlocking Peak Performance

Hard anodizing precisely transforms CNC aluminum parts, delivering superior durability and performance essential for demanding applications across diverse industries.

Why Your Parts Demand More

The Hidden Cost of Underperforming Parts

Components that fail to meet stringent performance specifications can lead to significant repercussions. This includes costly reworks, extensive product recalls, and ultimately, severe product failures in the field.

Such deficiencies not only erode customer confidence but also strain budgets, impacting long-term profitability. Inconsistent surface finishes or uneven coatings directly contribute to these issues.

Hard Anodizing: A Critical Advantage

Hard anodizing provides a robust solution, transforming the surface of CNC aluminum parts into a durable, ceramic-like layer. This process significantly enhances their resistance to wear, corrosion, and electrical breakdown.

It is an indispensable surface treatment for applications where conventional finishes simply cannot provide the required level of protection and longevity. The result is superior part performance and extended operational life.

Your Path to Superior Components

What You’ll Master in This Guide

This guide will comprehensively explore the electrochemical principles underpinning hard anodizing. We will delve into its unique performance benefits and practical applications for CNC aluminum parts.

Understanding these aspects is crucial for specifying optimal surface treatments that align with your product’s performance requirements.

Previewing Our Deep Dive

We aim to equip you with in-depth technical knowledge, offering best practices and solutions to common challenges. This approach ensures your designs achieve peak performance and reliability.

Our insights are designed to empower both procurement managers and R&D engineers in making informed material and process decisions.

Principles of Hard Anodizing

Defining Hard Anodic Coatings

Key Terms: Hardness & Thickness

Hardness, typically measured in Vickers (HV) or Rockwell (HRC), quantifies the coating’s resistance to indentation. Hard anodizing yields significantly higher hardness compared to standard anodizing.

Thickness, measured in micrometers (µm), dictates the coating’s overall protective capacity. Achieving precise thickness control is paramount for optimal performance and maintaining critical part tolerances.

Table: Typical Hard Anodic Coating Properties

| Property | Typical Range (Type III Hard Anodize) |

|---|---|

| Thickness | 25 – 150 µm |

| Surface Hardness | 350 – 600 HV (Vickers) |

| Density | 2.5 – 3.0 g/cm³ |

| Dielectric Strength | ~2000 V/mil |

The Electro-Chemical Process Explained

Hard anodizing is an electrochemical conversion process where the surface of an aluminum part is transformed into a dense, non-conductive layer of aluminum oxide. This occurs within a sulfuric acid electrolyte, often at low temperatures and high current densities.

The controlled growth of this anodic layer creates a highly organized, porous structure that is then typically sealed. This sealing step further enhances corrosion resistance and reduces porosity.

Why Hard Anodizing Excels

Beyond Basic Anodizing: Core Benefits

While standard anodizing provides good aesthetic and moderate protection, hard anodizing is engineered for extreme environments. It creates a much thicker, denser, and harder ceramic-like layer.

This superior structure offers dramatically enhanced wear resistance, improved corrosion protection, and significant dielectric strength, crucial for high-performance applications.

Table: Hard Anodizing vs. Standard Anodizing

| Feature | Standard Anodizing (Type II) | Hard Anodizing (Type III) |

|---|---|---|

| **Primary Goal** | Aesthetics, moderate protection | Wear, corrosion, dielectric |

| **Typical Thickness** | 5 – 25 µm | 25 – 150 µm |

| **Surface Hardness** | 200 – 300 HV | 350 – 600 HV |

| **Wear Resistance** | Good | Excellent |

| **Corrosion Resistance** | Good (with sealing) | Excellent (with sealing) |

| **Dielectric Strength** | Moderate | High |

Performance & Application Insights

Enhancing Part Durability

Unmatched Wear Resistance for Aluminum

The micro-hardness achieved through hard anodizing significantly reduces friction and abrasion on the surface of CNC aluminum parts. This makes them ideal for components subjected to constant mechanical stress or sliding contact.

Taber Abrasion Test results consistently demonstrate the superior wear characteristics of hard anodized aluminum, outperforming many hardened steels in specific applications.

Superior Corrosion & Electrical Shielding

Hard anodic coatings offer exceptional resistance to a wide range of corrosive agents, including salt spray, chemicals, and industrial atmospheres. This protective barrier extends the lifespan of components in harsh environments.

Furthermore, the dielectric properties of hard anodized layers provide effective electrical insulation. This is critical for applications requiring electrical isolation between conductive parts or as an insulator in electronic assemblies.

Real-World Hard Anodizing Success

Case Study: Aerospace Component Longevity

Problem: A client in the aerospace industry faced premature failure of critical CNC aluminum hydraulic manifold blocks. These components experienced high abrasive wear from fluid flow and required stringent resistance to hydraulic fluid corrosion.

Their previous supplier’s anodizing process resulted in inconsistent coating thickness and insufficient hardness, leading to expensive maintenance and operational downtime for their ‘Anodized Aluminum Performance’.

Our Solution: ly-machining engineers collaborated closely with the client, analyzing the specific operational stresses and material composition of their CNC aluminum parts. We optimized our hard anodizing process, meticulously controlling electrolyte composition, temperature, and current density.

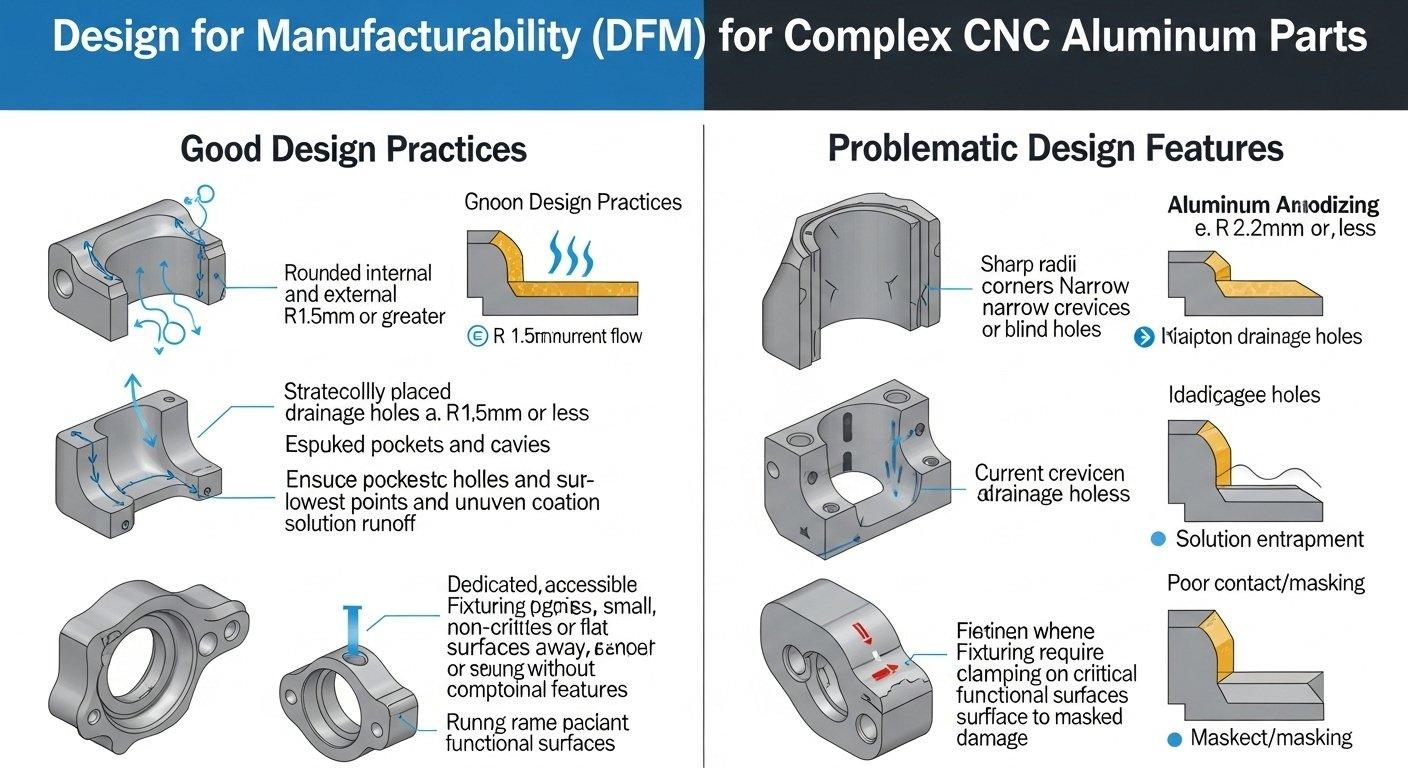

This ensured a consistently thick, dense, and exceptionally hard Type III hard anodized layer. We also provided design for manufacturability (DFM) feedback to enhance part geometry for optimal coating uniformity.

Result: The hard anodized hydraulic blocks from ly-machining demonstrated a 250% increase in operational lifespan, significantly reducing wear-related failures. The enhanced corrosion resistance also ensured long-term integrity against hydraulic fluids.

This solution not only eliminated costly unscheduled maintenance but also bolstered the client’s confidence in the sustained ‘Anodized Aluminum Performance’ of their critical systems.

Challenges & Advanced Solutions

Overcoming Common Anodizing Issues

FAQs: Tolerances, Color, & Adhesion

Hard anodizing adds thickness to a part, directly impacting critical dimensions and tolerances. It is crucial to account for this growth during the design and machining phases to maintain dimensional accuracy.

Color control in hard anodizing is primarily influenced by the aluminum alloy composition and coating thickness, often resulting in natural shades of grey, bronze, or black.

Achieving optimal adhesion of the hard anodic layer relies on proper surface preparation, including meticulous cleaning and de-smutting before the electrochemical process.

Table: Impact of Hard Anodizing on Tolerances

| Parameter | Typical Anodic Layer Thickness | Resulting Tolerance Change (per surface) |

|---|---|---|

| Inner Diameter | 25 – 150 µm | Reduces diameter by (2 x thickness) |

| Outer Diameter | 25 – 150 µm | Increases diameter by (2 x thickness) |

| Flat Surface | 25 – 150 µm | Increases dimension by thickness |

Future of CNC Aluminum Finishes

Optimizing for Complex CNC Aluminum Parts

For complex CNC aluminum parts, achieving uniform hard anodizing requires specialized fixturing and precise control over electrolyte flow. Alloy selection also plays a critical role in the final coating properties.

Different aluminum alloys respond distinctly to hard anodizing, influencing coating hardness, thickness, and color. Early consultation during design ensures optimal material choice and process parameters.

Table: Hard Anodizing Response of Common Aluminum Alloys

| Aluminum Alloy Type | Typical Response to Hard Anodizing | Notes |

|---|---|---|

| 6061 | Good, uniform, dark grey-brown | Common, general purpose alloy |

| 7075 | Good, harder, light to dark grey | High strength, aerospace applications |

| 2024 | Moderate, tends to be darker/softer | Copper content can affect uniformity |

| 5052 | Good, lighter, harder | Good for marine, architectural |

Your Next Step to Excellence

Key Takeaways for Hard Anodizing

Reaffirming Core Value for CNC Parts

Hard anodizing elevates the intrinsic value of CNC aluminum parts by providing a robust, long-lasting surface solution. This directly translates into enhanced product reliability and reduced lifecycle costs.

Partnering with an experienced source manufacturer ensures consistency and adherence to the most stringent performance specifications for your ‘Anodized Aluminum Performance’.

Summarizing Performance & Principles

We have explored how the electrochemical transformation of aluminum creates a superior ceramic-like layer, offering unparalleled wear, corrosion, and dielectric resistance. This scientific process is critical for demanding applications.

Understanding these principles allows for informed decisions, optimizing part design and material selection to fully leverage the benefits of ‘Hard Anodizing’ on ‘CNC Aluminum Parts’.

Partner for Precision & Quality

Get Your Expert Hard Anodizing Quote

Ready to achieve unparalleled performance for your CNC aluminum parts? Leverage our deep technical expertise as a source manufacturer with over a decade of experience in advanced ‘Aluminum Anodizing’.

Contact us today for a free technical consultation and a transparent, no-obligation quote tailored to your exact hard anodizing specifications.

FAQ Section

How does hard anodizing impact tolerances?

Hard anodizing typically adds thickness to the surface of CNC aluminum parts, which directly affects dimensional tolerances. This growth is generally uniform, with approximately half the coating thickness penetrating the substrate and half building on the surface.

Therefore, designers must factor this dimensional change into their initial machining specifications. Precise control of the anodizing process allows for predictable and repeatable tolerance management on your ‘CNC Aluminum Parts’.

Can hard anodized parts be colored?

While hard anodizing can be dyed, the resulting colors are typically darker and more muted than those achieved with standard anodizing. Common shades include bronze, grey, or black.

The final color is highly dependent on the aluminum alloy used and the specific thickness of the hard anodic layer. For purely aesthetic applications, standard ‘Aluminum Anodizing’ might offer a broader range of vibrant colors.

What prevents hard anodizing corrosion?

Hard anodizing provides exceptional corrosion resistance by creating a dense, non-porous aluminum oxide barrier on the ‘Anodized Aluminum Performance’. This layer is chemically stable and isolates the base metal from corrosive environments.

Further enhancement is achieved through sealing processes, which fill the microscopic pores in the anodic layer. This significantly improves resistance to chemical attack and environmental degradation.