Precision CNC for Bicycle Parts: Mastering Tolerance Control

Imagine a bicycle component so perfectly machined that it shaves milliseconds off a race time or eliminates annoying rattles on a long tour. The difference isn’t magic; it’s the mastery of CNC machining precision and tolerance control. But how many manufacturers truly deliver on that promise?

The subtle deviations in bicycle parts CNC machining can compromise performance, shorten lifespan, and lead to significant assembly challenges. True engineering excellence lies in eliminating these variables, ensuring every component functions flawlessly.

This article will delve into the critical aspects of precision CNC for bicycle parts, exploring the methodologies and technologies that guarantee unparalleled accuracy, delivering superior product integrity and unlocking new levels of innovation.

Achieving industry-leading precision in bicycle parts CNC machining requires a deep understanding of tolerance control and advanced manufacturing techniques.

Flawless Ride Goals

Setting the Scene & Posing the Question

Why Inaccurate Bicycle Parts Fail Riders

Minor dimensional inaccuracies in bicycle parts CNC machining can propagate into significant operational issues. A slight misalignment in a gear cassette or a minuscule runout on a disc brake rotor directly translates to compromised functionality.

These subtle flaws can lead to inefficient power transfer, premature wear of mating components, and an overall degradation of the riding experience. For performance-critical applications, such deviations are simply unacceptable.

The Hidden Value of Micro-Precision in Bicycle Parts

Beyond basic fitment, micro-precision in bicycle parts CNC machining delivers tangible performance advantages. It ensures seamless integration, reduced friction, and enhanced durability, transforming a functional part into a performance enhancer.

The commitment to tight tolerances not only prevents failures but also elevates a bicycle’s responsiveness and rider confidence. This meticulous attention to detail underpins superior product quality and brand reputation.

Core Argument & Content Preview

Unlocking Superior Bicycle Performance

The pursuit of superior bicycle performance is inextricably linked to the precision of its components. From lightweight frames to intricate gear systems, every part’s dimensional accuracy is paramount.

Our approach to bicycle parts CNC machining focuses on achieving geometric perfection, ensuring that each component contributes optimally to the overall system’s efficiency and longevity. This dedication sets a new standard for quality.

Exploring Precision, Processes, and Solutions for Control

This article will systematically unpack the fundamental concepts of precision and tolerance, detail the advanced methodologies employed in bicycle parts CNC machining, and present solutions for common challenges. We will emphasize how our engineering expertise translates into tangible benefits.

Our aim is to provide an in-depth guide, demonstrating how strict adherence to precision control yields components that meet the most demanding specifications of bicycle manufacturers and enthusiasts alike.

Precision Essentials

Concepts & Foundational Theories

What “CNC Machining Precision” Truly Means

CNC machining precision refers to the ability to produce parts with dimensions and features that consistently fall within extremely tight specified limits. It encompasses both dimensional accuracy and geometric accuracy.

This requires not only state-of-the-art machinery but also sophisticated programming, controlled environmental conditions, and rigorous metrology techniques. It is a holistic approach, not merely a single capability.

Geometric Dimensioning & Tolerancing Basics

Geometric Dimensioning and Tolerancing (GD&T) is a symbolic language used on engineering drawings to precisely define the nominal geometry of a part and its allowable variation. It is crucial for unambiguous communication of design intent.

For bicycle parts CNC machining, GD&T ensures that components not only fit together but also function correctly under dynamic loads. It is a critical tool for achieving interchangeability and repeatable performance.

Here are some fundamental GD&T concepts often applied to bicycle parts:

| GD&T Feature | Description for Bicycle Parts |

|---|---|

| Flatness | Ensures surfaces like brake mounts are truly flat for optimal contact. |

| Perpendicularity | Guarantees components like disc brake rotors are perfectly square to their mounting face. |

| Concentricity | Critical for bearing fits in hubs or bottom brackets, ensuring smooth rotation. |

| Positional Tolerance | Defines the precise location of features like bolt holes in a frame or caliper. |

Relevance & Practical Value

How Tight Tolerances Boost Bicycle Part Performance

Tight tolerances in bicycle parts CNC machining directly translate to enhanced performance and rider safety. For instance, precise bearing seats minimize friction, increasing efficiency and reducing wear.

Similarly, accurately machined mating surfaces for suspension components ensure smooth travel and predictable handling. Every millimicron of accuracy contributes to a superior riding experience and product longevity.

Achieving Accuracy

Methodologies & Application Framework

Advanced CNC Strategies for Bicycle Components

Our factory employs advanced CNC strategies tailored for bicycle parts, utilizing multi-axis machining capabilities to achieve complex geometries in a single setup. This minimizes part handling and reduces cumulative errors.

High-speed machining combined with optimized tool paths and cutting parameters is essential for maintaining material integrity and achieving superior surface finishes, which is critical for lightweight, performance-focused bicycle components.

Mitigating Errors: Best Practices in Tolerance Control

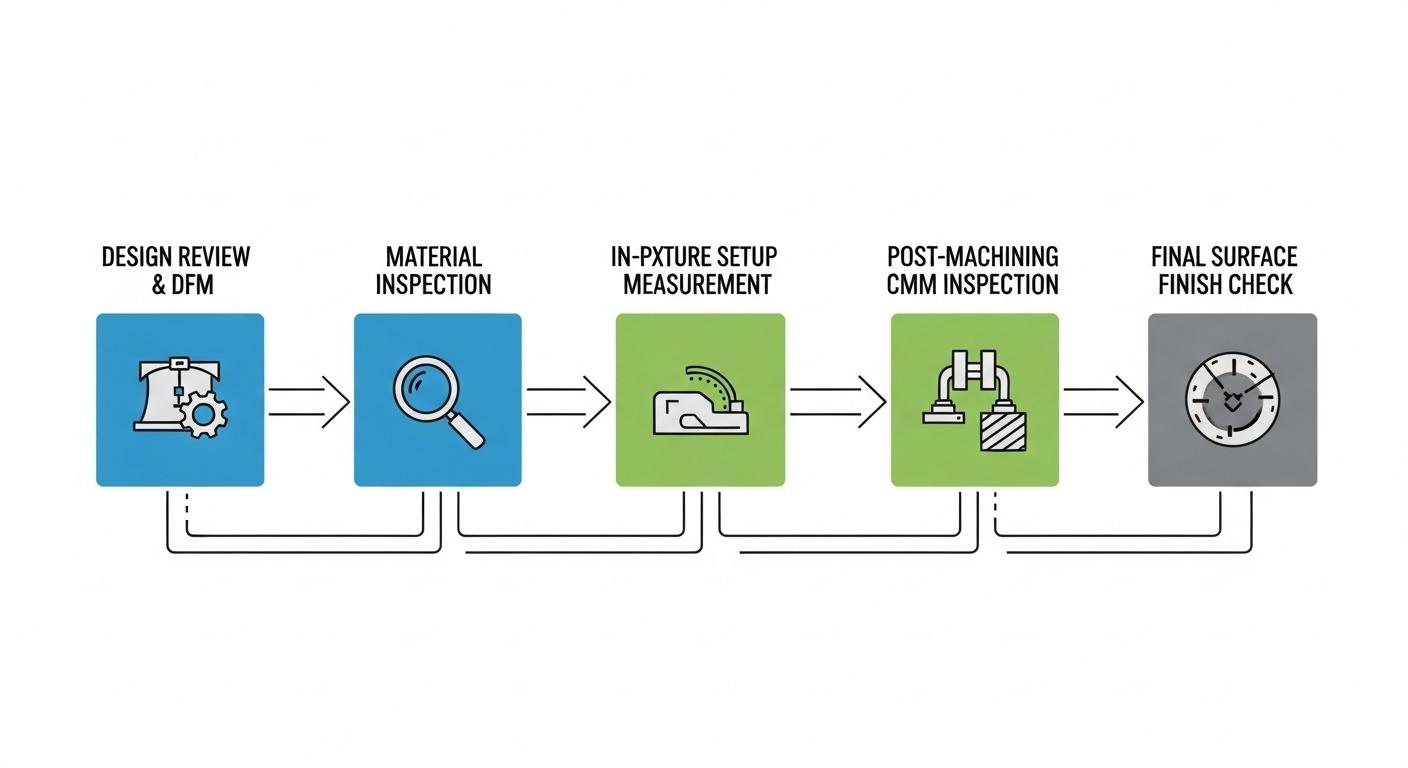

Effective tolerance control begins at the design stage with Design for Manufacturability (DFM) analysis. It continues through precise programming, selection of optimal cutting tools, and robust fixture design.

In-process measurement and adaptive machining play a vital role in real-time error detection and compensation. This proactive approach minimizes deviations and ensures consistent quality in bicycle parts CNC machining.

Case Studies & Comparative Insights

Real-World Precision: A Bicycle Component Success

A client approached us with a challenging design for a lightweight, high-performance bicycle suspension link. The part required exceptionally tight positional tolerances for multiple bearing bores and critical surface flatness for optimal damping. Initial attempts with other manufacturers resulted in unacceptable runout and frequent assembly failures.

Our solution involved leveraging our 5-axis CNC capabilities and advanced metrology. We developed a proprietary fixturing strategy to maintain rigidity throughout machining and implemented 100% CMM inspection for all critical features. This ensured every part met the demanding specifications.

The result was a suspension link that provided flawless operation, significantly improved the bicycle’s handling characteristics, and eliminated assembly issues, leading to a measurable increase in our client’s product satisfaction and market reputation.

Comparing Quality: The Performance Difference in Parts

The difference between a moderately tolerant bicycle part and a high-precision one can be stark. While both might function, their longevity, performance, and overall rider experience diverge significantly.

| Attribute | Moderately Tolerant Part (Typical) | High-Precision Part (Our Standard) |

|---|---|---|

| Bearing Lifespan | Prone to premature wear, noise | Extended lifespan, silent operation |

| Assembly Ease | May require forcing, shimming | Smooth, precise fit, no adjustments |

| Power Transfer | Minor efficiency losses | Maximized efficiency, direct power |

| Durability | Susceptible to fatigue, early failure | Enhanced fatigue resistance, robust |

| Ride Feel | Some play, occasional squeaks | Solid, responsive, quiet |

Future & Fixes

Solving Common Precision Pain Points

Addressing Post-Machining Deflection

Post-machining deflection, often due to residual stresses or thin-wall sections, can compromise the precision of bicycle parts. Our engineers employ stress-relieving techniques, optimized cutting strategies, and specialized fixturing to minimize this effect.

Through iterative process optimization and advanced simulation, we predict and counter potential deformations, ensuring the final part retains its designed dimensional integrity. This is particularly crucial for complex bicycle components.

Future of CNC & Smart Tolerance Control

The future of bicycle parts CNC machining lies in greater automation, real-time adaptive control, and the integration of AI-driven analytics. These technologies will enable even tighter tolerances and more complex geometries.

Smart tolerance control systems, leveraging in-situ sensors and machine learning, will predict and correct deviations before they occur. This continuous feedback loop represents the next frontier in manufacturing precision.

Advanced Techniques & Industry Trends

Optimizing Designs for CNC Precision

Collaborating with designers early in the product development cycle is crucial for optimizing designs for CNC precision. Our engineering team provides DFM feedback to ensure manufacturability without compromising performance.

This involves selecting appropriate materials, designing features with minimal tool access challenges, and specifying tolerances realistically yet effectively to achieve the desired functionality. It’s a partnership in innovation.

Next Steps

Key Takeaways & Reinforcement

Recapping Your Journey to Precision Control

We have explored the foundational importance of precision and tolerance control in bicycle parts CNC machining, from theoretical concepts to practical applications. The consistency and performance of bicycle components are directly tied to manufacturing accuracy.

Our factory’s commitment to advanced methodologies, meticulous quality control, and an engineer-centric approach ensures that every part we produce meets the most stringent demands for accuracy and reliability.

Summing Up: Mastered Tolerances Mean Peak Performance

Mastered tolerances are not merely a technical specification; they are the bedrock of peak performance for any bicycle. They reduce friction, enhance durability, and ultimately contribute to a superior, safer riding experience.

Choosing a manufacturing partner who understands and implements this level of precision is paramount for any bicycle brand aiming for excellence and innovation in its product line.

Invitation to Act

Partner for Unmatched Bicycle Part Precision

Elevate your bicycle component designs with uncompromising precision. Contact our expert engineering team today for a complimentary technical consultation and transparent quote. Let’s engineer your next generation of high-performance bicycle parts.

FAQ Section

What is bicycle parts CNC machining?

Bicycle parts CNC machining refers to the automated manufacturing process where computer-controlled machines precisely cut and shape raw materials into components. This method is crucial for creating high-performance, accurate bicycle parts.

It ensures consistency, repeatability, and the ability to produce complex geometries essential for modern bicycle designs. This precision is vital for the optimal function of critical components.

Why are tight tolerances important?

Tight tolerances are critical because they ensure that bicycle components fit together perfectly and operate smoothly without excessive friction or play. This directly impacts performance, durability, and rider safety.

Inaccurate parts can lead to premature wear, inefficient power transfer, and potential component failure during use. Precision guarantees reliability and extends product lifespan.

What materials can be CNC machined?

A wide range of materials are suitable for bicycle parts CNC machining, including various aluminum alloys (e.g., 6061, 7075), titanium, stainless steel, and certain high-performance plastics. Material selection depends on the component’s specific functional requirements.

Each material offers unique properties regarding strength, weight, corrosion resistance, and machinability. Our engineers can advise on the optimal material choice for your specific bicycle component needs.