Precision CNC for Complex Aluminum Enclosures

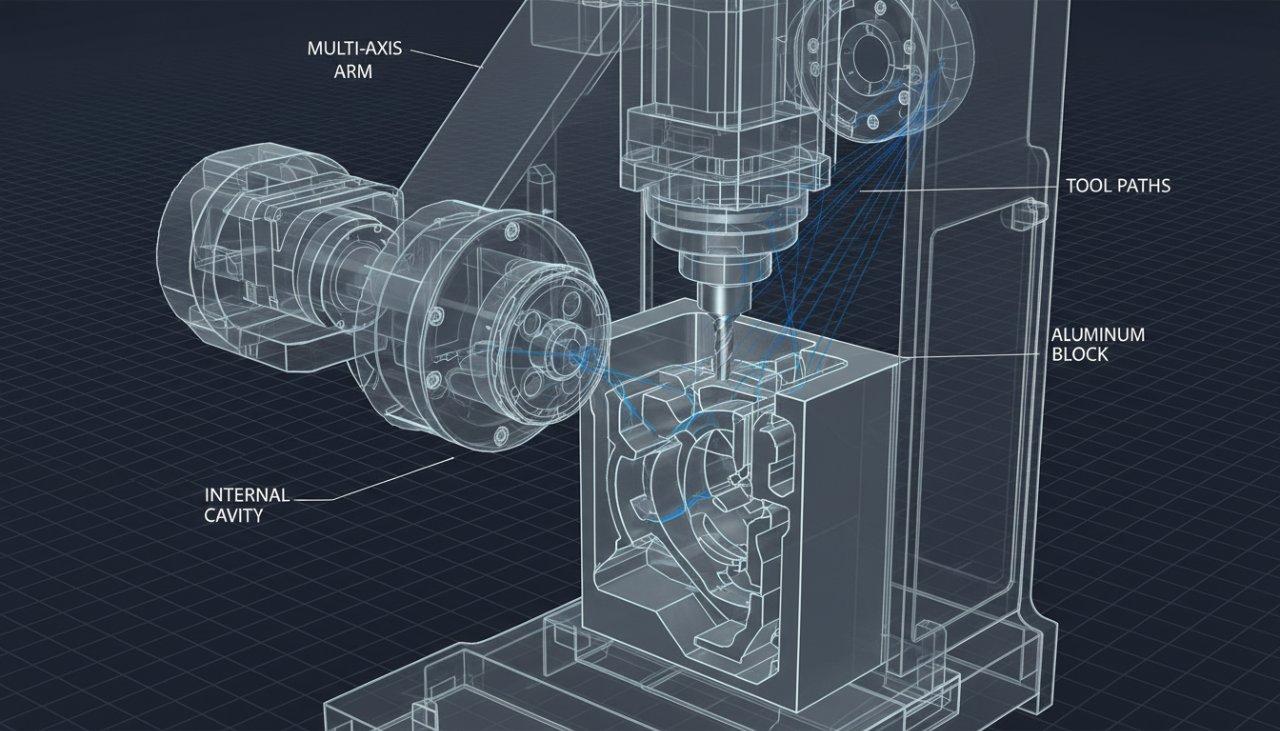

Precision CNC machining, leveraging robotic and collaborative arm control, enables flawless production of complex aluminum enclosures, positioning ly-machining as a leading aluminum shell CNC machining manufacturer and aluminum CNC machining supplier for custom aluminum parts.

The demands on modern manufacturing are constantly escalating, especially for intricate components like aluminum enclosures. Engineers and designers face immense pressure to innovate, often pushing the boundaries of traditional fabrication methods. This is where advanced CNC machining, particularly with robotic and collaborative arm integration, truly shines.

In ly-machining’s experience, the precise control and efficiency offered by these technologies are not just advantageous; they are essential. We specialize in transforming the most challenging designs for custom aluminum enclosures and complex cavities into tangible, high-quality products, ensuring your projects achieve unparalleled success.

The Challenge of Complex Aluminum Cavity Machining

Demands for high-precision aluminum parts manufacturing services

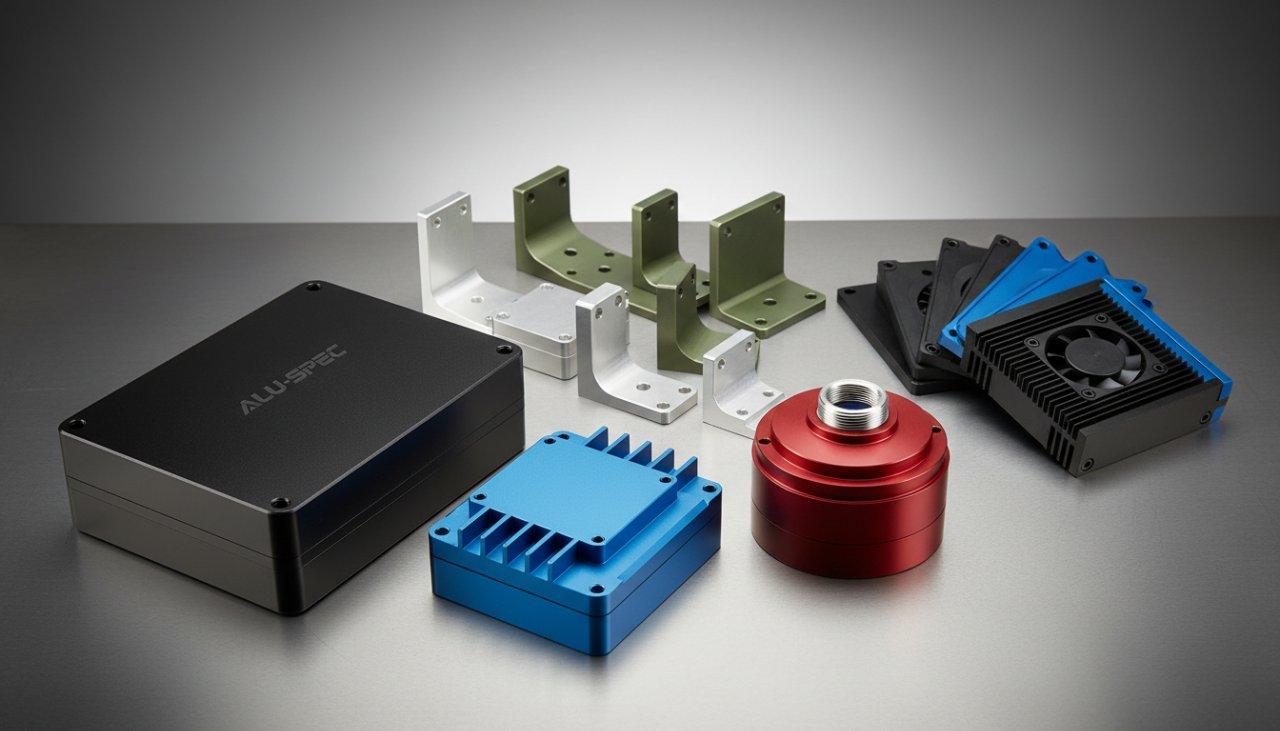

The market for high-performance devices, from aerospace to medical, increasingly relies on custom aluminum enclosures. These applications demand not just aesthetic appeal but also extreme dimensional accuracy and structural integrity.

This critical need drives the constant search for an aluminum shell CNC machining manufacturer capable of delivering exceptional quality. ly-machining understands these stringent requirements, providing aluminum parts manufacturing services that meet and exceed expectations.

Overcoming intricate geometry with advanced CNC machining

Manufacturing aluminum parts with intricate internal geometries presents significant hurdles. Traditional CNC machining often struggles with deep, narrow pockets, undercuts, and features requiring multiple setups.

These complexities demand not just skilled operators but also advanced multi-axis CNC machinery. ly-machining employs state-of-the-art equipment to navigate these challenges, ensuring precise material removal and feature creation.

Common pain points for custom aluminum enclosures

Clients frequently face issues such as extended lead times, high tooling costs, and inconsistent quality when outsourcing custom aluminum enclosures. These pain points often stem from a lack of integrated advanced technology.

Another common issue ly-machining sees is the difficulty in achieving specific surface finishes within complex cavities. This requires specialized tooling and meticulous process control, which many suppliers cannot consistently provide.

Robotics in Precision Aluminum Shell CNC Machining

Automation benefits for aluminum shell CNC machining manufacturer

Integrating robotics into CNC machining processes offers transformative benefits for an aluminum shell CNC machining manufacturer. Automation significantly reduces manual intervention, minimizing human error and improving safety.

For ly-machining, this means enhanced consistency across production batches, leading to higher quality parts. Robotic systems allow for continuous operation, boosting throughput and overall manufacturing efficiency.

Enhancing throughput and quality with advanced CNC machining

Robotics play a crucial role in optimizing the entire CNC machining workflow. Collaborative robotic arms can perform repetitive tasks such as part loading and unloading much faster and more consistently than human operators.

This automation frees up skilled technicians at ly-machining to focus on programming, quality control, and process optimization. The result is a significant increase in production throughput without compromising the meticulous quality required for aluminum parts manufacturing services.

The role of robotics in DFM for custom aluminum enclosures

Design for Manufacturability (DFM) is paramount for complex custom aluminum enclosures. Robotics assist in DFM by enabling faster prototyping and iterative design cycles.

ly-machining utilizes robotic simulation to optimize tool paths and fixture designs before physical production begins. This proactive approach helps identify and mitigate potential manufacturing issues, saving time and resources in the long run.

Collaborative Robotic Arm Control for Aluminum Casings

Safety and flexibility in aluminum parts manufacturing services

Collaborative robotic arms are designed to work alongside human operators, offering unprecedented safety and flexibility in aluminum parts manufacturing services. They feature advanced sensors that detect human presence, allowing for safe interaction in shared workspaces.

This versatility enables ly-machining to deploy automation precisely where it’s needed without extensive safety caging, streamlining our production floor. The adaptability of collaborative robots means rapid reconfiguration for different part types.

Optimizing tool changes and inspection for CNC machining

One of the significant advantages of collaborative robotic arms in CNC machining is their ability to automate auxiliary tasks. They can perform rapid tool changes, reducing machine downtime and increasing overall operational efficiency.

Furthermore, collaborative robots can assist with in-process and post-process inspection. By integrating vision systems, they can verify critical dimensions or surface finishes, ensuring that every aluminum component meets stringent quality standards established by ly-machining.

Future-proofing your needs with an aluminum CNC machining supplier

Partnering with an aluminum CNC machining supplier that embraces collaborative robotics ensures your projects are future-proof. These adaptable systems can scale with evolving production demands and design complexities.

ly-machining’s investment in collaborative technology signifies our commitment to continuous improvement and advanced capabilities. We are equipped to handle the next generation of intricate custom aluminum enclosures and precision components.

Mastering Complex Cavity CNC Machining Processes

Multi-axis capabilities for challenging custom aluminum enclosures

Mastering complex cavity machining for custom aluminum enclosures is impossible without multi-axis CNC capabilities. ly-machining leverages 5-axis simultaneous machining to access intricate features from various angles in a single setup.

This eliminates the need for multiple re-fixturing operations, which reduces setup time and accumulation of errors. The result is higher precision, better surface finish, and greater design freedom for our clients’ demanding applications.

Achieving superior surface finish in aluminum parts manufacturing services

Achieving a superior surface finish within complex aluminum cavities is a hallmark of quality aluminum parts manufacturing services. ly-machining employs specialized cutting tools, optimized feed rates, and high-pressure coolant systems.

Our expert machinists and engineers fine-tune every parameter to minimize tool marks and achieve desired surface roughness values. This meticulous attention ensures both functional performance and aesthetic excellence for every part.

Table: Common Aluminum Alloys and Their Machinability

| Aluminum Alloy | Typical Applications | Machinability Rating (0-10) |

|---|---|---|

| 6061 | Structural, general | 8 |

| 7075 | Aerospace, high-stress | 6 |

| 2024 | Aircraft, fasteners | 7 |

| 5052 | Marine, electronics | 6 |

Quality control and inspection for intricate CNC machining

Rigorous quality control and inspection protocols are fundamental to ly-machining’s intricate CNC machining processes. Every custom aluminum enclosure undergoes comprehensive checks at various stages.

ly-machining utilizes advanced metrology equipment, including CMMs (Coordinate Measuring Machines) and optical scanners, to verify critical dimensions and tolerances. This ensures that every part conforms precisely to design specifications, guaranteeing reliability for our aluminum parts manufacturing services.

Table: Quality Control Checkpoints

| Phase | Inspection Method | Focus Areas |

|---|---|---|

| Raw Material | Material Certification | Alloy composition, hardness |

| In-Process | Vision Systems, Probes | Tool wear, dimensional drift |

| Post-Machining | CMM, Optical Scan | Final dimensions, GD&T, surface |

Your Expert Aluminum Shell CNC Machining Partner

Why choose a source aluminum shell CNC machining manufacturer

Choosing a source aluminum shell CNC machining manufacturer like ly-machining means working directly with the experts who design and execute the manufacturing process. This eliminates intermediaries, enhancing communication and transparency.

It also ensures greater control over quality, lead times, and cost, providing a more reliable supply chain. ly-machining offers unparalleled expertise from initial design consultation through final production, supporting your custom aluminum enclosures needs.

Transparent pricing and unparalleled aluminum parts manufacturing services

ly-machining is committed to transparent pricing without hidden fees, a core principle of our aluminum parts manufacturing services. We provide detailed quotes that break down costs, allowing clients to understand the value proposition clearly.

Our dedication to efficiency and quality allows us to offer competitive pricing for even the most complex CNC machining projects. This commitment builds long-term trust and fosters strong client relationships.

Partnering for success in custom aluminum enclosures projects

Partnering with ly-machining means collaborating with a team deeply invested in your success. Our engineers provide valuable Design for Manufacturability (DFM) insights, optimizing designs for cost-effectiveness and performance.

We work closely with clients to understand their specific requirements and challenges for custom aluminum enclosures. This collaborative approach ensures that our aluminum parts manufacturing services deliver solutions that perfectly align with project goals.

Ready for Precision? Contact Our CNC Machining Experts

Get a consultation from a leading aluminum CNC machining supplier

If you’re seeking an aluminum CNC machining supplier capable of tackling the most challenging aluminum shell CNC machining projects, ly-machining is your ideal partner. Our expertise in robotic and collaborative arm control for complex cavity machining sets us apart.

Let ly-machining’s technical team review your design and provide expert recommendations. We are dedicated to delivering precision, efficiency, and exceptional value for your next generation of custom aluminum enclosures and intricate components.

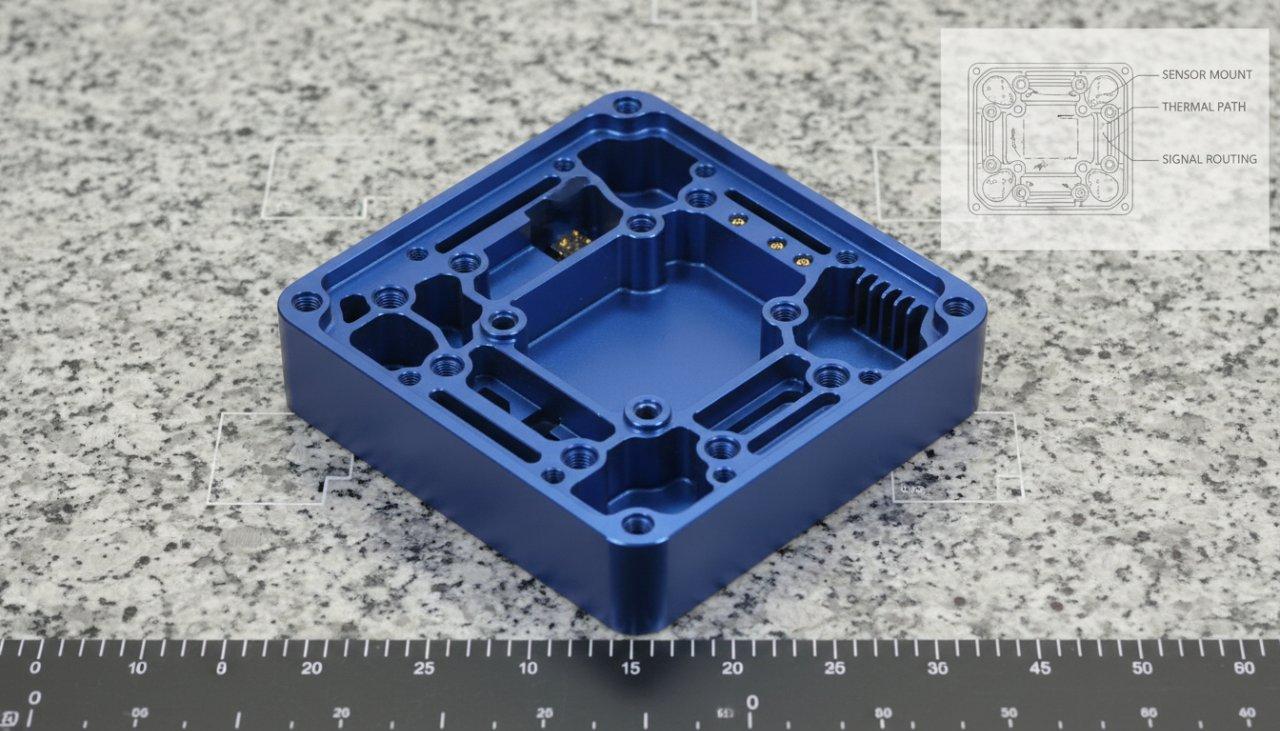

Case Study: Revolutionizing a Robotics Sensor Housing

Problem: A client approached ly-machining with a new robotics sensor housing requiring an incredibly complex internal cavity for optical components, demanding sub-micron tolerances and a pristine surface finish in 7075 aluminum. Their previous aluminum shell CNC machining manufacturer struggled with repeatability and maintaining acceptable yields due to the intricate geometry and material properties. This bottleneck delayed their product launch.

Solution: ly-machining implemented a specialized 5-axis CNC machining program, fully integrated with collaborative robotic arm part loading and unloading. This automation ensured consistent positioning and reduced human interaction, minimizing errors. Our engineers developed custom fixturing and optimized tool paths, leveraging high-speed precision milling techniques and real-time adaptive control to maintain the tight tolerances and superior surface finish within the complex cavity.

Result: By partnering with ly-machining, the client achieved a 98% yield rate, far exceeding their previous supplier’s capabilities. Production cycle times were reduced by 30%, accelerating their market entry. The consistent quality and precision of the custom aluminum enclosures allowed them to confidently scale production, establishing ly-machining as their trusted aluminum CNC machining supplier for future projects.

Ready to elevate your complex aluminum enclosure projects with unparalleled precision and efficiency? Contact ly-machining’s technical experts today for a personalized consultation and a transparent quote. Let’s transform your most ambitious designs into flawless reality.

How does ly-machining ensure precision for complex cavities?

ly-machining ensures precision through a combination of advanced technologies. We utilize 5-axis CNC machining, enabling access to intricate features in a single setup. This minimizes errors and achieves superior geometric accuracy.

Our processes are further enhanced by robotic automation for consistent part handling. We also employ rigorous metrology, including CMMs, to verify every critical dimension.

What are the benefits of collaborative robotics for my project?

Collaborative robotics offers significant benefits for your custom aluminum enclosures. They improve production efficiency by automating repetitive tasks like loading and unloading, reducing cycle times.

They also enhance consistency and quality by minimizing human error. Moreover, these systems offer flexible deployment, allowing for adaptable manufacturing solutions that can scale with your project needs.

Can ly-machining help with Design for Manufacturability (DFM)?

Yes, ly-machining provides comprehensive DFM support for custom aluminum enclosures. Our expert engineers collaborate with your design team from conception.

We offer insights to optimize designs for precision, cost-effectiveness, and efficient production processes. This proactive approach ensures your designs are manufacturable with the highest quality.