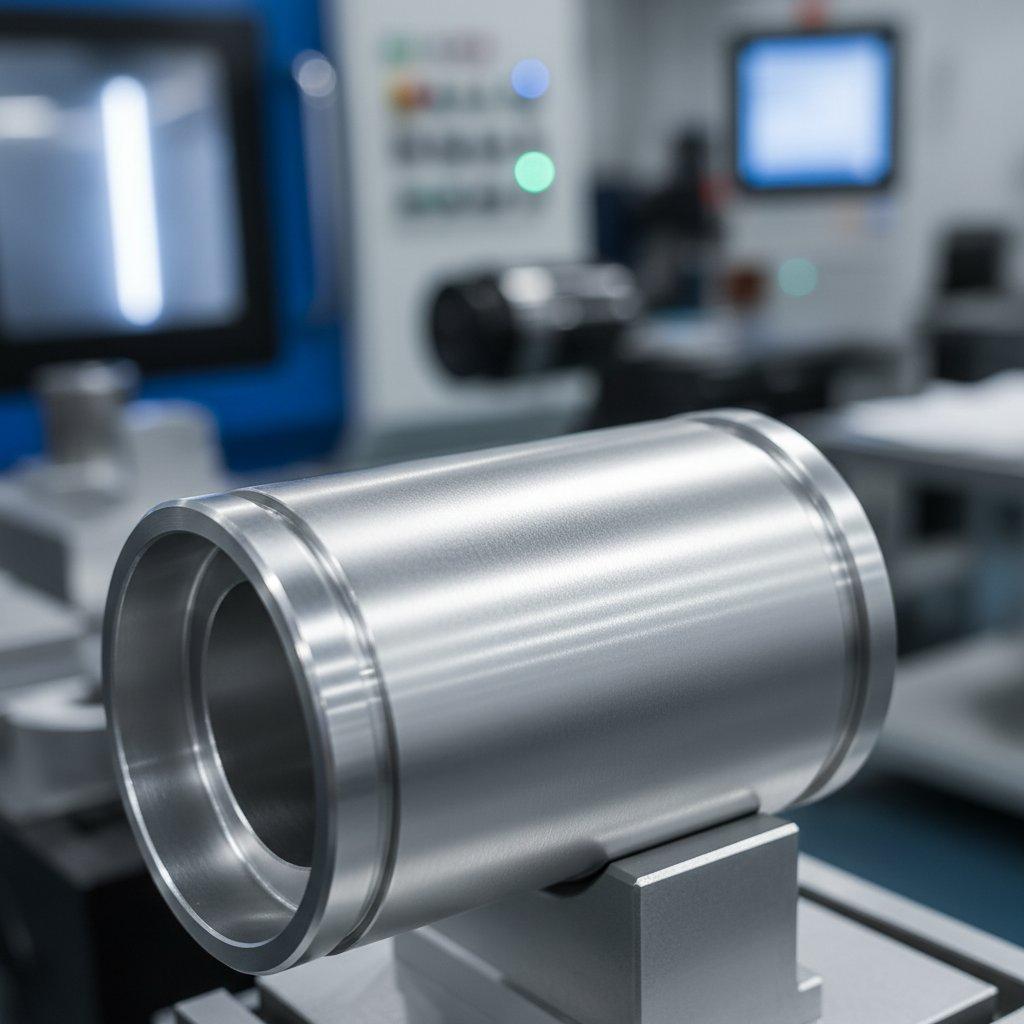

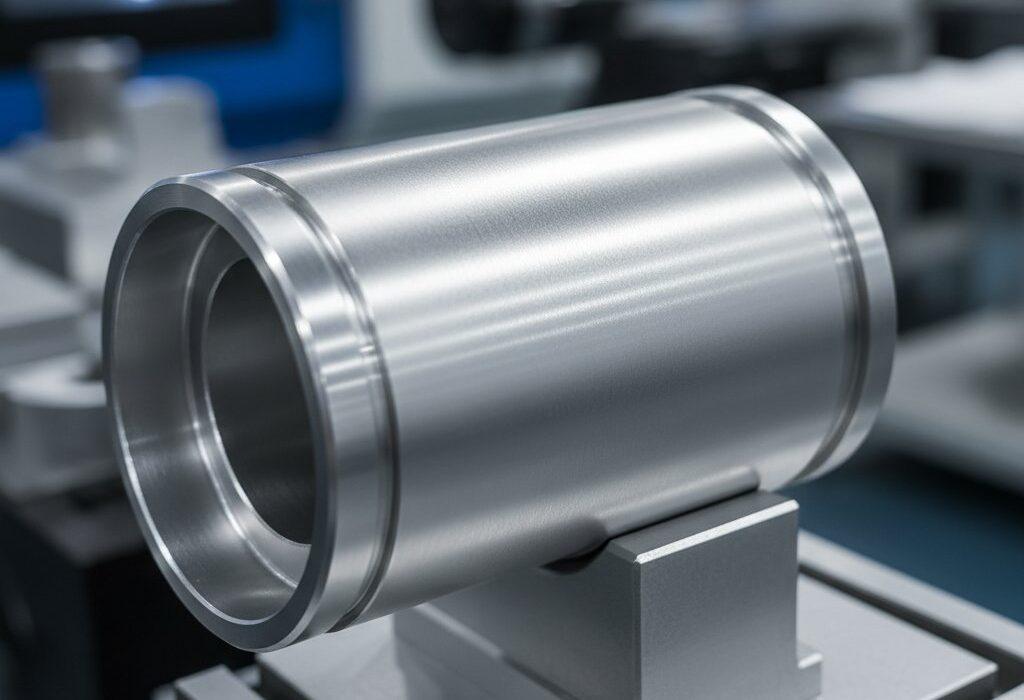

Precision CNC Machining Companies: Custom Optical Instrument Components with Ra0.2 Surface

Precision CNC machining companies, like ly-machining, deliver custom optical instrument components with Ra0.2 surface finishes by integrating advanced CNC parts manufacturing services, specialized tooling, and rigorous quality control for unparalleled optical performance.

Achieving superior optical performance in modern instruments hinges entirely on the precision of their internal components. Inconsistent surface finishes on critical optical parts can compromise an instrument’s function, leading to light scattering, optical aberrations, and ultimately, product failure. For demanding applications, an ultra-fine Ra0.2 surface finish isn’t just an aspiration; it’s a non-negotiable requirement for true optical clarity and unwavering precision.

This article will delve into the technical challenges and expert solutions ly-machining provides for manufacturing high-precision optical instrument components. ly-machining’s deep technical expertise as a leading provider of custom CNC machined components ensures that even the most stringent specifications, such as Ra0.2 surface roughness, are consistently met. Discover how partnering with an experienced source manufacturer can accelerate your product development and elevate your optical instrument’s capabilities.

The Challenge of Optical Instrument Parts

Optical instruments demand components engineered to tolerances far beyond standard mechanical parts. The unique environment within a telescope, microscope, or specialized sensor requires every element to contribute positively to optical performance. Any compromise in dimensional accuracy or surface finish can degrade the final image or data quality.

Why Precision CNC Machining is Critical for Optics

Precision CNC machining is the bedrock of modern optical instrument manufacturing. It allows for the creation of complex geometries and features with micron-level accuracy, essential for optical alignment and function. ly-machining leverages state-of-the-art CNC machining to produce parts where every detail matters.

The interplay of multiple optical elements requires extreme concentricity, perpendicularity, and parallelism of mechanical components. ly-machining’s computer numerical control services are specifically tailored to achieve these intricate relationships. This ensures that lens barrels and housing units maintain precise optical axes.

Overcoming Tolerance Demands in Custom Components

Optical components often require extremely tight dimensional tolerances, sometimes down to a few microns. Achieving these on custom CNC machined components demands not only advanced machinery but also profound engineering knowledge. ly-machining addresses these challenges through meticulous process planning and continuous in-process measurement.

Maintaining concentricity for bore diameters over varying lengths is particularly challenging for lens barrels. ly-machining’s experience in manufacturing these critical parts involves sophisticated fixturing and multi-axis CNC machining centers. This approach minimizes runout and ensures perfect optical alignment.

Achieving Surface Ra0.2 Control in Lens Barrels

The Ra0.2 surface finish specification for optical instrument components is exceptionally stringent, crucial for preventing light scattering and maintaining signal integrity. This level of smoothness requires a holistic approach, starting from material selection and extending through advanced machining and finishing.

Material Selection for CNC Parts Manufacturing Services

The choice of material is foundational for achieving an Ra0.2 surface finish. Different alloys possess varying machinability characteristics, affecting chip formation and surface integrity. ly-machining guides clients through material selection to optimize for both optical performance and machinability.

Common materials for optical components include various grades of aluminum, stainless steel, and specialty alloys. Each has distinct properties that influence the machining parameters required to achieve ultra-fine finishes. ly-machining’s expertise ensures the right material is chosen for the specific application.

| Material Type | Common Grade | Key Advantage | Suitability for Ra0.2 |

|---|---|---|---|

| Aluminum | 6061-T6 | Lightweight, Machinable | Good |

| Aluminum | 7075-T6 | High Strength, Wear Resistance | Good |

| Stainless Steel | 303, 304 | Corrosion Resistance | Moderate |

| Specialty | Titanium | Strength, Biocompatible | Moderate |

Advanced CNC Machining Techniques for Ra0.2

Achieving an Ra0.2 surface is not simply about using the sharpest tool; it involves a symphony of advanced CNC machining techniques. ly-machining employs multi-axis machining, optimized tool paths, and specific cutting parameters to minimize surface imperfections directly during the machining phase.

High-speed machining (HSM) with specialized diamond-tipped or polished carbide tools plays a crucial role. Precise spindle speeds, feed rates, and depth of cut are fine-tuned for each material. ly-machining’s skilled technicians continually monitor and adjust these parameters to achieve the desired surface quality.

| Technique | Description | Impact on Ra0.2 |

|---|---|---|

| Multi-Axis Machining | Simultaneous movement of multiple axes for complex geometries. | Improved part rigidity, better surface integrity. |

| Optimized Tool Paths | Smooth, continuous tool engagement to minimize chatter. | Reduced surface defects, uniform finish. |

| High-Speed Machining | Very high spindle speeds with light cuts. | Produces mirror-like finishes, less tool wear. |

| Precision Tooling | Polished carbide, diamond-tipped inserts. | Minimizes micro-scratches and burrs. |

Post-Processing for Precision CNC Machining Companies

Even with superior CNC machining, post-processing is often essential to achieve and verify an Ra0.2 surface. Precision CNC machining companies utilize various finishing techniques to refine the surface further and remove any microscopic irregularities left by cutting tools.

Techniques such as precision micro-polishing, vibratory finishing, or specialized deburring can enhance the surface quality. ly-machining meticulously selects the appropriate post-processing method to ensure the Ra0.2 specification is met without compromising dimensional accuracy.

Our Expertise in High-Precision CNC Machining Parts

ly-machining stands out as a leader in providing high-precision CNC machining parts for the optical industry. ly-machining’s comprehensive capabilities and unwavering commitment to quality set the standard for custom optical component manufacturing. ly-machining understands that optical precision requires mechanical excellence.

As Source CNC Machining Manufacturers of Parts

As direct CNC machining manufacturers of parts, ly-machining offers unparalleled control over the entire production process. From initial design consultation and material sourcing to final inspection and delivery, ly-machining manages every step. This integrated approach ensures consistent quality and efficient lead times.

Clients benefit from ly-machining’s transparent communication and direct access to engineers. ly-machining’s role as a source manufacturer means fewer intermediaries and greater accountability. This translates into reliable, high-quality CNC parts manufacturing services tailored to specific optical applications.

Quality Assurance in Custom CNC Machined Components

Quality assurance at ly-machining is not just a final check; it’s an integral part of every stage of production. For custom CNC machined components requiring an Ra0.2 surface, ly-machining employs advanced metrology equipment and stringent inspection protocols. This ensures every part adheres to the exact specifications.

ly-machining utilizes non-contact optical profilometers, surface roughness testers, and high-precision CMMs to verify surface finish and dimensional accuracy. Adherence to ISO 9001 and AS9100 standards underpins ly-machining’s quality management system, providing complete traceability and reliability.

Transparent Pricing for CNC Parts Manufacturing Services

ly-machining believes in clear and transparent pricing for all CNC parts manufacturing services. ly-machining provides detailed quotes that break down costs, ensuring clients understand the investment required for high-precision components like those demanding an Ra0.2 finish. No hidden fees or unexpected charges disrupt project budgets.

ly-machining’s efficiency as a source manufacturer often results in competitive pricing without compromising quality. ly-machining strives to be a long-term partner, offering cost-effective solutions that deliver exceptional value. This fosters trust and enables long-term collaboration.

Benefits of Partnering for Optical Parts

Choosing the right precision CNC machining companies can significantly impact the success of your optical instrument project. Partnering with a specialist like ly-machining offers distinct advantages, from accelerated development to mitigated risks. ly-machining acts as an extension of your R&D and manufacturing teams.

Accelerating Your Development with Precision CNC Machining

Streamlined project timelines are critical in today’s fast-paced market. ly-machining’s expertise in precision CNC machining allows for rapid prototyping and efficient production of complex optical components. This accelerates your product development cycle, getting your innovations to market faster.

ly-machining’s design for manufacturability (DFM) guidance helps optimize designs for precision and cost-effectiveness from the outset. By identifying potential manufacturing challenges early, ly-machining helps prevent costly delays and reworks, ensuring smooth project execution.

Reducing Risks with Expert CNC Machining Companies

The risks associated with unreliable suppliers can be substantial, including project delays, quality failures, and reputational damage. By partnering with reputable precision CNC machining companies like ly-machining, you significantly reduce these risks. ly-machining’s proven track record and rigorous quality systems provide peace of mind.

ly-machining’s comprehensive quality control, adherence to industry standards, and financial stability ensure a dependable supply chain. This minimizes the risk of component failure in your final optical instruments. ly-machining is a trusted partner committed to your success.

Get Your High-Precision Lens Barrel Quote Today

Elevate your optical instrument’s performance and accelerate your development cycle by partnering with ly-machining. ly-machining specializes in delivering the most demanding custom CNC machined components, including those requiring an exacting Ra0.2 surface finish. ly-machining is ready to address your complex challenges.

Consult Our Experts for Custom CNC Machined Components

ly-machining invites you to consult ly-machining’s deep technical experts today for a transparent quote. ly-machining offers a free consultation on your high-precision lens barrel or custom optical component requirements. Discover the difference of partnering with a source manufacturer.

ly-machining is committed to Ra0.2 excellence and precision. ly-machining’s team is eager to discuss how ly-machining’s advanced CNC machining capabilities can bring your most ambitious optical instrument designs to life. Reach out now to start a conversation.

FAQ Section

What is Ra0.2 surface finish?

An Ra0.2 surface finish refers to an average roughness of 0.2 micrometers. It is an extremely fine and smooth surface, crucial for applications where minimizing friction, wear, and light scattering is critical.

Achieving this level of finish requires specialized machining techniques. It also demands meticulous post-processing, and rigorous inspection processes.

Why is Ra0.2 important for optical parts?

For optical instrument components, an Ra0.2 surface finish is vital to prevent light scattering and unwanted reflections. Any microscopic imperfections can diffract or scatter light. This degrades the instrument’s image quality and overall performance.

It ensures that the mechanical components do not negatively impact the optical path. It supports the precision required for high-fidelity optical systems.

How does ly-machining ensure Ra0.2?

ly-machining ensures Ra0.2 by combining advanced multi-axis CNC machining, optimized tool paths, and specialized cutting tools. ly-machining carefully selects materials with excellent machinability.

Additionally, ly-machining employs precision post-processing techniques. ly-machining uses non-contact optical profilometers for stringent quality verification and adherence to industry standards like ISO 9001.