Precision CNC Manufacturer: Technical Strength Is Key

When seeking a precision CNC machining partner, technical strength is paramount for ensuring quality and reliability. The right `CNC factory recommendation` hinges on a provider’s `CNC machining expertise` to deliver `precision CNC machining` with unwavering consistency.

Are you constantly battling inconsistent part quality or delayed shipments from your CNC machining suppliers? You’re not alone. In precision manufacturing, the difference between project success and costly failure often hinges on one critical factor: the `technical strength` of your chosen manufacturer.

This guide will illuminate what true `precision CNC machining expertise` entails, offering a comprehensive framework to evaluate potential partners. We delve into how a manufacturer’s deep `technical strength` directly translates into unparalleled part quality, risk mitigation, and innovative solutions, ensuring your projects consistently exceed expectations.

The Challenge of Precision CNC Machining

Achieving exacting specifications in modern manufacturing is a continuous challenge. Components demand ever-tighter tolerances, superior surface finishes, and the ability to work with advanced materials. This complexity places immense pressure on machining operations.

Why Standard Machining Falls Short

Standard machining processes often lack the necessary precision and control for demanding applications. They may struggle with intricate geometries, specific material requirements, or the dimensional accuracy vital for mission-critical parts.

This can lead to significant issues, including excessive material waste and frequent rework. The cumulative impact of these inefficiencies often results in delayed project timelines and escalated production costs for clients.

Common Pitfalls in CNC Sourcing

A common pitfall we encounter involves clients choosing suppliers based solely on initial low bids. This approach often overlooks crucial aspects like the manufacturer’s `technical strength`, quality control, and problem-solving capabilities.

Another frequent issue is a lack of transparency regarding capabilities and pricing structures. Without clear communication, unexpected costs or limitations can emerge late in a project, causing significant disruption and frustration.

Defining True Technical Strength

True `technical strength` in `precision CNC machining` extends far beyond just owning machines. It encompasses a holistic approach involving engineering acumen, advanced technology, material mastery, and stringent quality protocols.

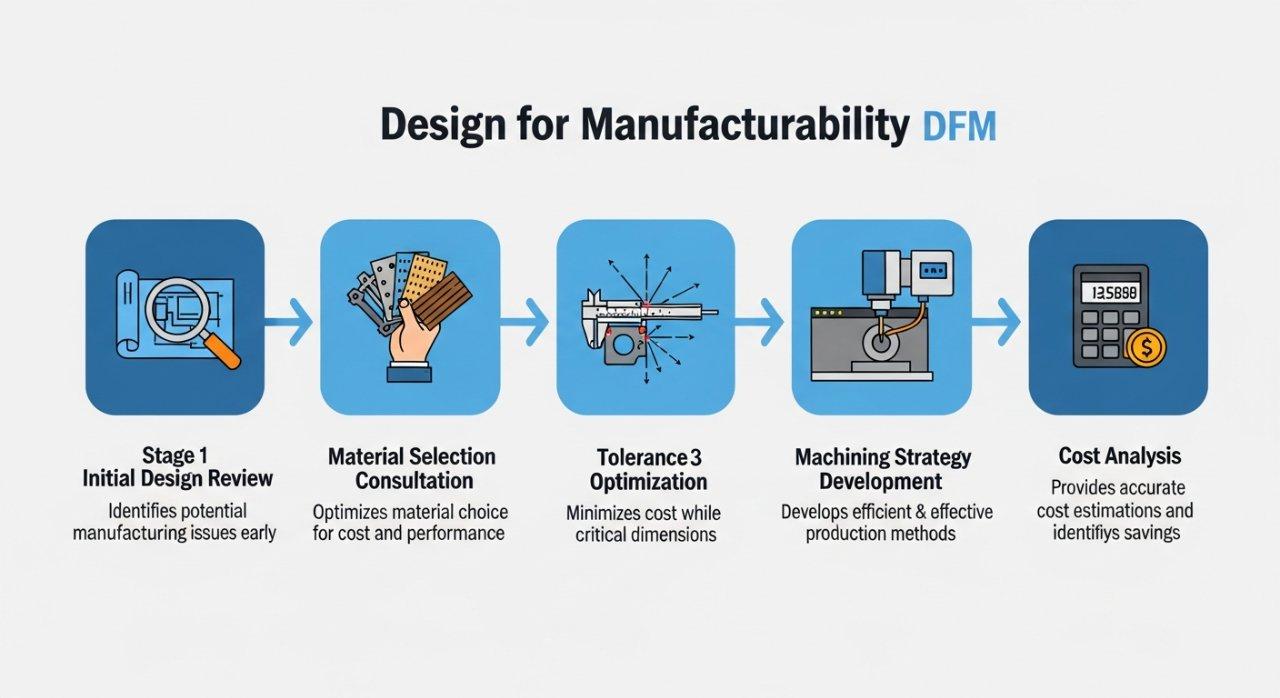

Engineering & Design for Manufacturability (DFM)

Our engineers don’t just execute designs; they actively collaborate to optimize them for production. Design for Manufacturability (DFM) is crucial for identifying potential issues early, streamlining processes, and ensuring cost-effective, high-quality outcomes.

This proactive approach minimizes design iterations and production errors. It ensures that parts are not only functional but also efficiently manufacturable, saving both time and resources in the long run.

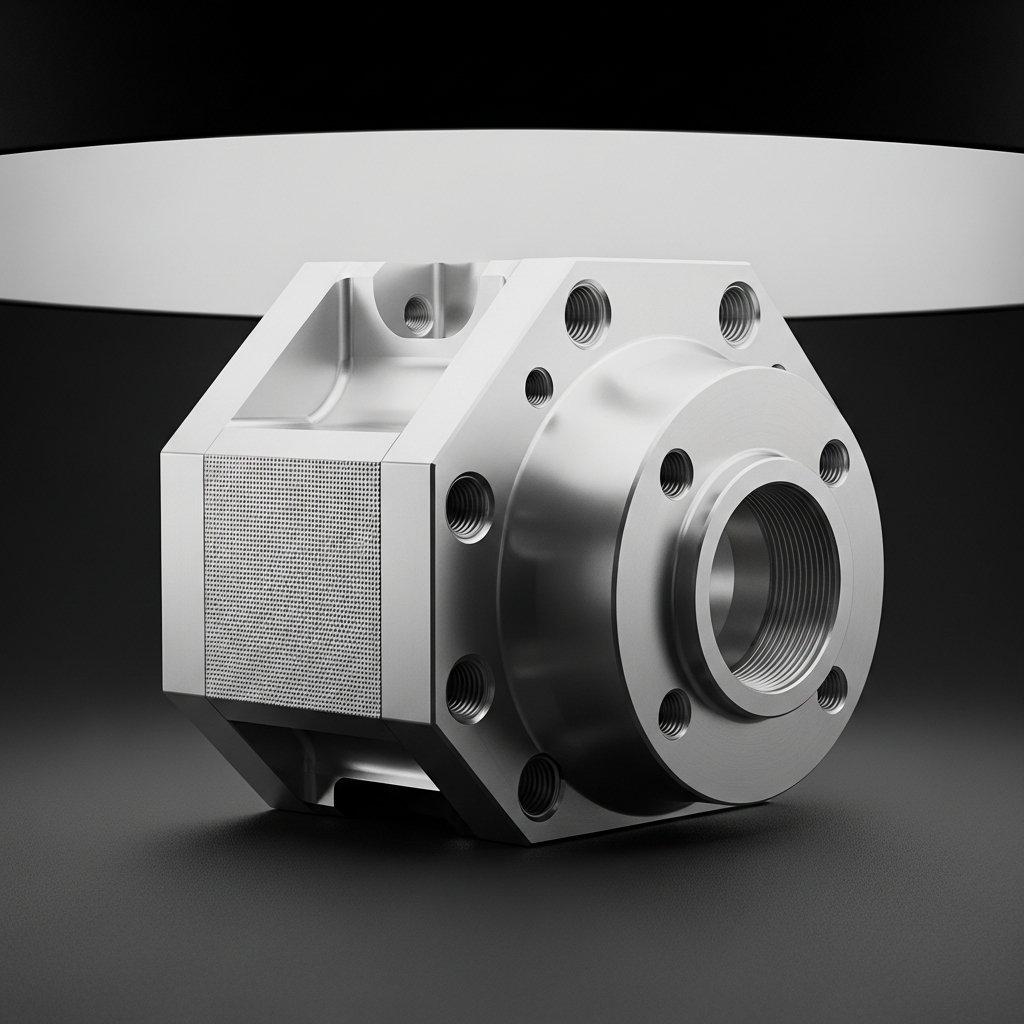

Advanced Machining Capabilities & Equipment

Our facility is equipped with state-of-the-art multi-axis CNC machines. These advanced systems enable us to produce highly complex geometries and maintain extremely tight tolerances across a wide range of materials, far exceeding conventional 3-axis limitations.

The sophisticated automation and precision offered by these machines ensure repeatable accuracy, even for the most demanding parts. This capability is foundational to delivering consistent, high-quality `precision CNC machining` services.

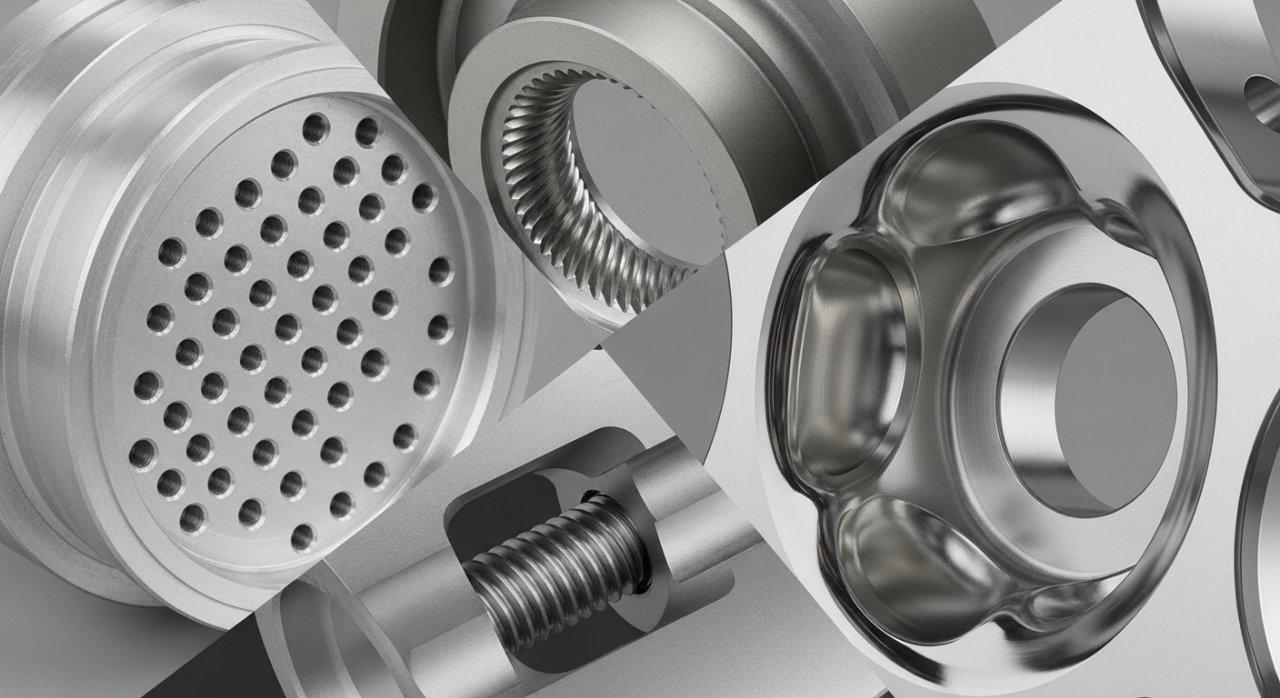

Material Science & Application Expertise

Understanding material properties is as vital as the machining itself. We possess deep expertise in working with diverse materials, including exotic alloys, high-performance plastics, and ceramics, each requiring specific machining strategies and parameters.

This knowledge ensures optimal material selection for your application, preventing common issues like material deformation or premature wear. Our proficiency in material science contributes directly to the longevity and performance of your components.

Rigorous Quality Control Systems & Inspection

Quality is not an afterthought; it’s embedded in every stage of our process. We adhere to stringent quality management systems, including ISO 9001 and AS9100 certifications, ensuring consistent adherence to the highest industry standards.

Our inspection processes utilize advanced metrology equipment, such as CMM (Coordinate Measuring Machine) and optical comparators. These tools provide precise dimensional verification, guaranteeing that every part meets or exceeds specified tolerances.

Technical Strength: Your Project’s Cornerstone

The inherent `technical strength` of a `CNC factory recommendation` directly underpins the success of your precision manufacturing projects. It transforms potential challenges into reliable outcomes.

Guaranteeing High-Quality Parts & Tolerances

Our profound `CNC machining expertise` ensures that every part we produce adheres to the strictest quality standards. We consistently achieve and maintain the tightest tolerances, often measured in microns, critical for high-performance applications.

This unwavering commitment to precision means you receive components that integrate seamlessly into your assemblies. It eliminates costly rejections and rework, guaranteeing the functionality and reliability your products demand.

Mitigating Risks & Ensuring On-Time Delivery

Leveraging our `technical strength` allows us to anticipate and resolve potential manufacturing hurdles proactively. This foresight significantly reduces production risks, preventing delays and ensuring project continuity.

Our robust processes and experienced team enable us to maintain strict production schedules, facilitating on-time delivery. We understand the critical importance of meeting deadlines in your supply chain and strive for consistent reliability.

Driving Innovation Through Collaborative Expertise

We act as an extension of your engineering team, offering collaborative `CNC machining expertise` to push design boundaries. Our technical insights can unlock new possibilities, transforming challenging concepts into manufacturable realities.

This partnership fosters innovation, allowing you to develop advanced products with confidence. We provide valuable feedback on material choices, design optimization, and machining strategies to enhance performance and reduce costs.

Transparent Pricing & Cost Efficiency Insights

Our status as a source manufacturer, combined with deep technical understanding, allows for highly transparent and accurate pricing. We provide detailed quotes that reflect the true cost of precision, avoiding hidden fees or unexpected charges.

Furthermore, our DFM expertise helps optimize designs for cost-effective production without compromising quality. We identify opportunities to streamline processes and material usage, leading to overall project cost efficiency.

How to Evaluate a CNC Factory’s Expertise

Choosing the right `precision CNC machining` partner requires a systematic evaluation of their `technical strength`. Go beyond surface-level comparisons to assess their core capabilities.

Questions to Ask Potential Manufacturers

When vetting a `CNC factory recommendation`, inquire about their specific experience with materials relevant to your project. Ask about their typical tolerance ranges and their methods for achieving and verifying them.

Probe into their quality control protocols, including their inspection equipment and certification status. Understanding their DFM capabilities and how they handle design challenges will reveal their problem-solving mindset.

Certifications & Industry Standards as Indicators

Look for certifications such as ISO 9001:2015, which signifies a commitment to quality management. For aerospace or medical applications, AS9100 or ISO 13485 are crucial indicators of specialized `technical strength` and compliance.

These certifications are not just badges; they represent audited processes and a disciplined approach to manufacturing. They serve as reliable benchmarks for a factory’s commitment to excellence and consistent performance.

Assessing Their Track Record & Case Studies

Request detailed case studies or examples of complex projects they’ve successfully completed. Pay attention to how they tackled unique challenges, their solutions, and the measurable results achieved for their clients.

A proven track record with diverse projects demonstrates versatility and depth of `CNC machining expertise`. Verifiable client testimonials or references can also provide valuable insight into their reliability and partnership approach.

Our CNC Technical Prowess

At ly-machining, our commitment to `technical strength` is the bedrock of our `precision CNC machining` services. We are dedicated to being the `CNC factory recommendation` you can trust.

As a Source Manufacturer: Our Unique Advantage

As a direct source manufacturer, we control every aspect of the `precision CNC machining` process, from material sourcing to final inspection. This direct oversight ensures unparalleled quality, consistency, and traceability for every component.

It also eliminates intermediaries, leading to more transparent communication and pricing. Our clients benefit from direct access to our engineering team, fostering a true collaborative partnership and efficient problem-solving.

Real-World Examples of Complex Solutions

We have a robust portfolio of successfully completed projects, ranging from intricate medical device components with micro-tolerances to high-stress aerospace parts crafted from exotic alloys. Our `CNC machining expertise` shines in these challenging scenarios.

Our engineering team thrives on tackling complex geometries and demanding material specifications. We transform your most ambitious designs into precisely manufactured realities, consistently exceeding expectations.

Partnership for Your Project’s Success

We believe that true partnership is built on trust, transparency, and shared goals. Our technical team works hand-in-hand with your engineers, offering insights and solutions that enhance your product’s performance and manufacturability.

Choosing ly-machining means selecting a partner committed to your success, providing not just parts, but comprehensive `CNC machining expertise` and support from concept to completion.

Unlock Your Project’s Potential Today

Ready to experience the reliability of true `technical strength` for your next `precision CNC machining` project?

**Call to Action:** Request a comprehensive technical consultation and transparent quote from our engineering team today.

What defines precision in CNC machining?

Precision in CNC machining refers to the ability to consistently produce parts with extremely tight dimensional tolerances and superior surface finishes. It involves advanced machinery, expert programming, and stringent quality control to achieve specifications often measured in microns.

How does DFM benefit my project?

Design for Manufacturability (DFM) benefits your project by identifying and resolving potential production issues early in the design phase. This proactive approach minimizes rework, reduces material waste, optimizes manufacturing processes, and ultimately lowers overall costs while maintaining high quality.

Why is a source manufacturer better?

A source manufacturer like ly-machining offers direct control over the entire production process, ensuring consistent quality, traceability, and streamlined communication. This eliminates intermediaries, leading to more transparent pricing and direct access to expert technical support, fostering a stronger partnership.