Precision Quality Control for Drone Parts CNC Machining

Rigorous quality control in CNC machining ensures mission-critical drone components achieve micron-level precision and peak performance, safeguarding reliability from concept to flight.

In the rapidly evolving world of drone technology, the difference between groundbreaking innovation and costly failure often lies hidden within a single micron. Every mission, every flight, every data point hinges on the unseen quality of your drone’s components. What if a single manufacturing defect could ground your entire operation?

This article will delve into how unwavering quality control in CNC machining safeguards your drone’s success. We will explore the critical principles, advanced techniques, and the unique advantages a source manufacturer like ly-machining brings to this highly specialized field.

Why Precision Matters in Drone Component Manufacturing

The High Stakes of Drone Parts: Failure Costs

Drone parts are inherently mission-critical. Any component failure can lead to catastrophic losses, including equipment damage, mission failure, or even safety hazards. The reliability of each custom drone part is paramount.

In ly-machining’s experience, even minute deviations in a CNC machined part can compromise the drone’s structural integrity or aerodynamic performance. This ripple effect underscores the absolute necessity for precision drone machining.

Essential Qualities for Custom Drone Parts CNC

The successful operation of a drone depends on components that exhibit exceptional strength-to-weight ratios and resistance to environmental factors. Precision is not just a preference; it is a fundamental requirement.

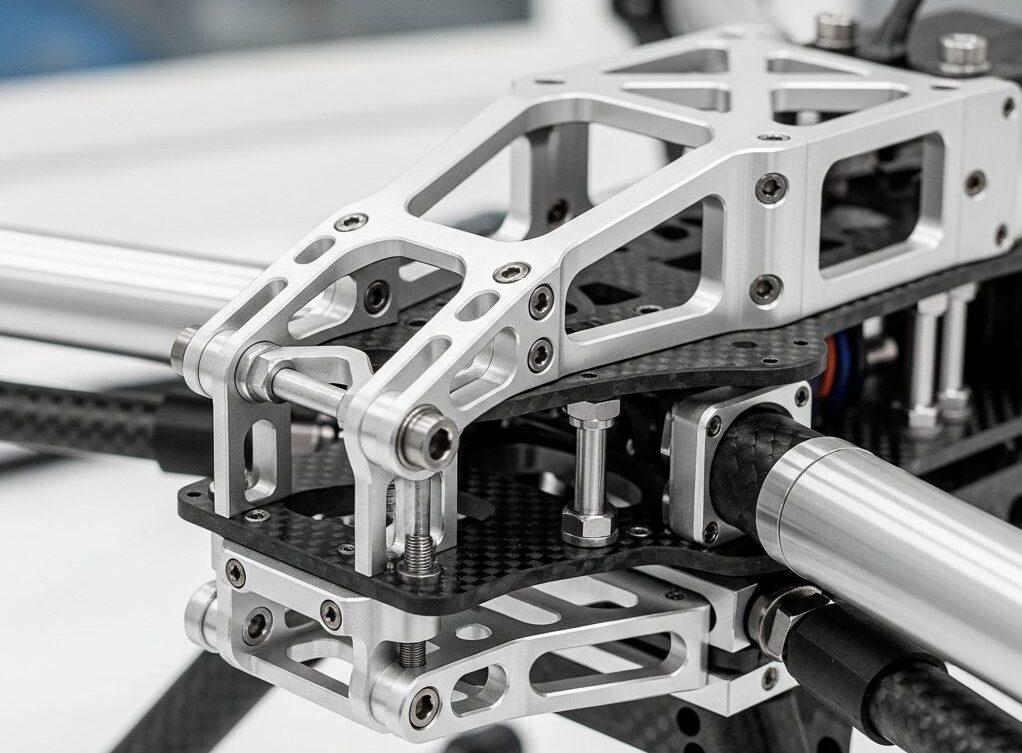

Custom drone parts CNC processing demands tight tolerances, superior surface finishes, and consistent material properties. These qualities ensure seamless assembly and reliable performance under dynamic flight conditions.

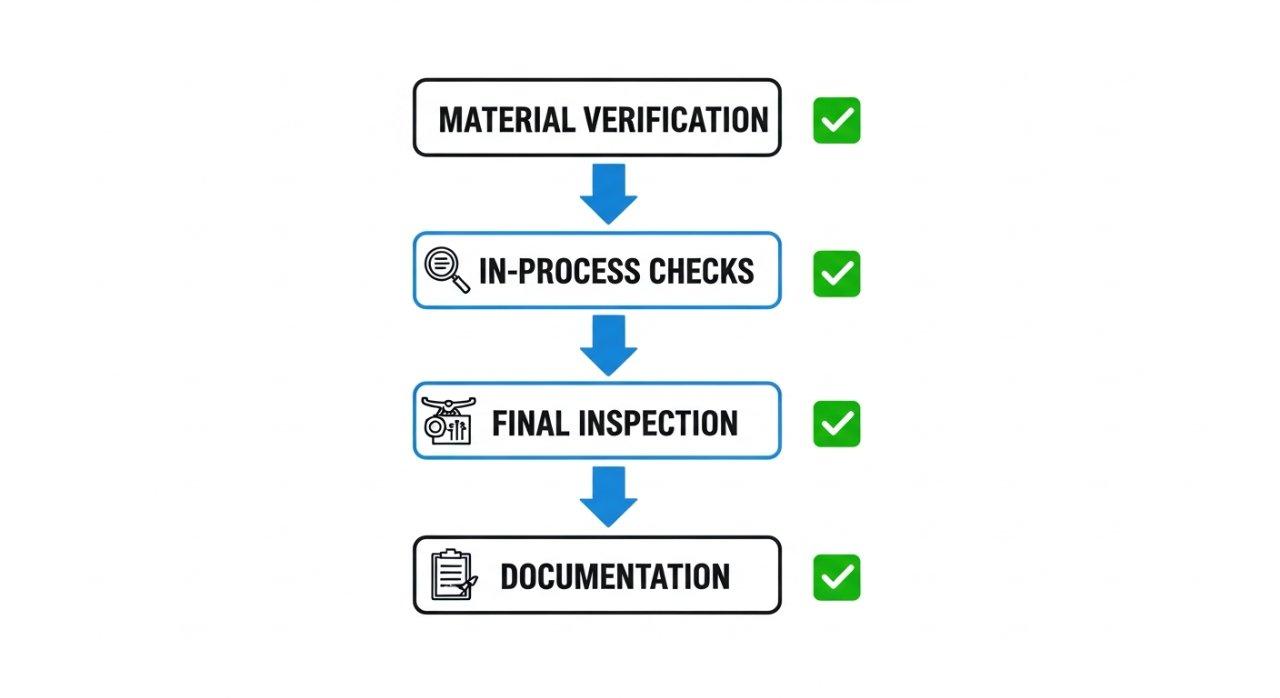

Core Principles of CNC Machining Quality Control

Material Selection and Verification for Drone Parts

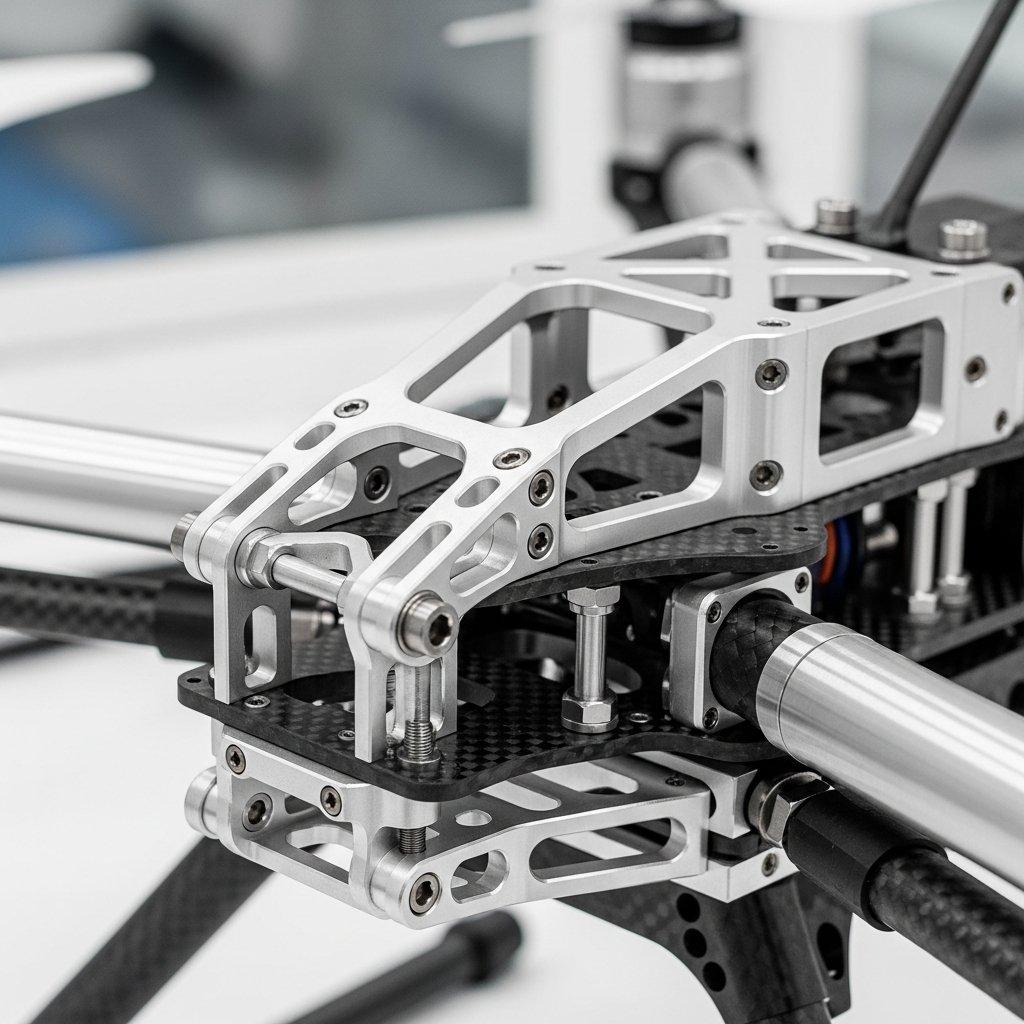

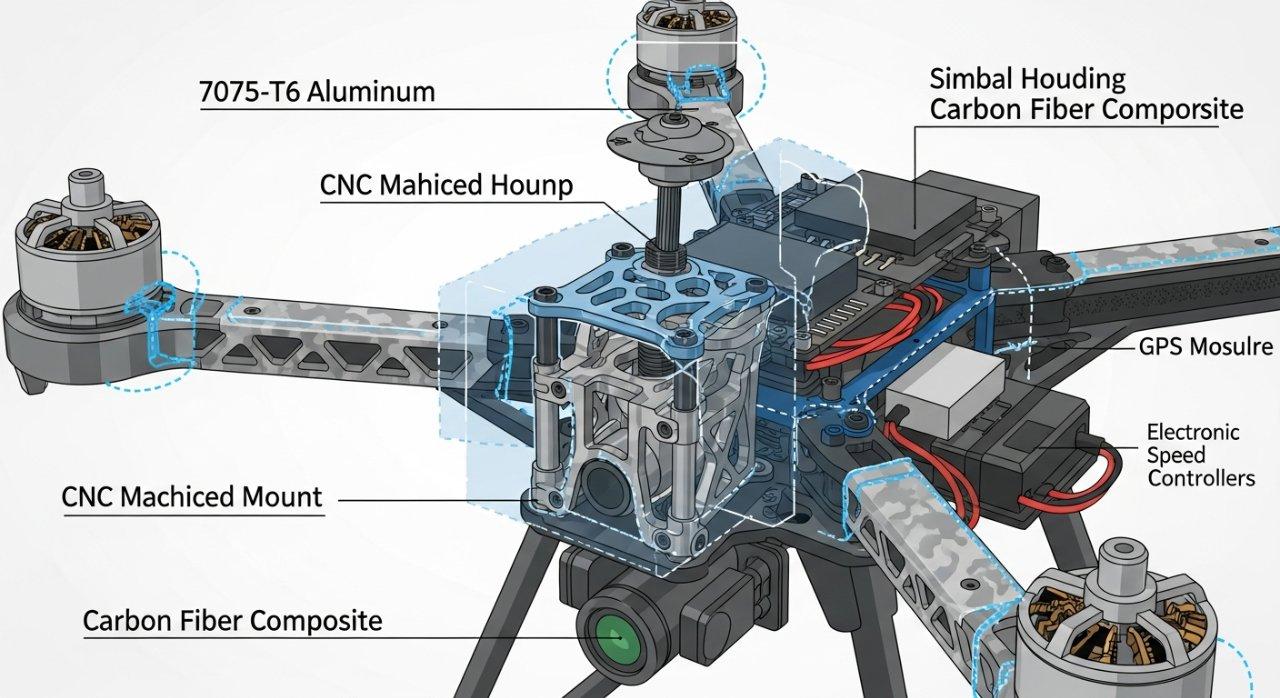

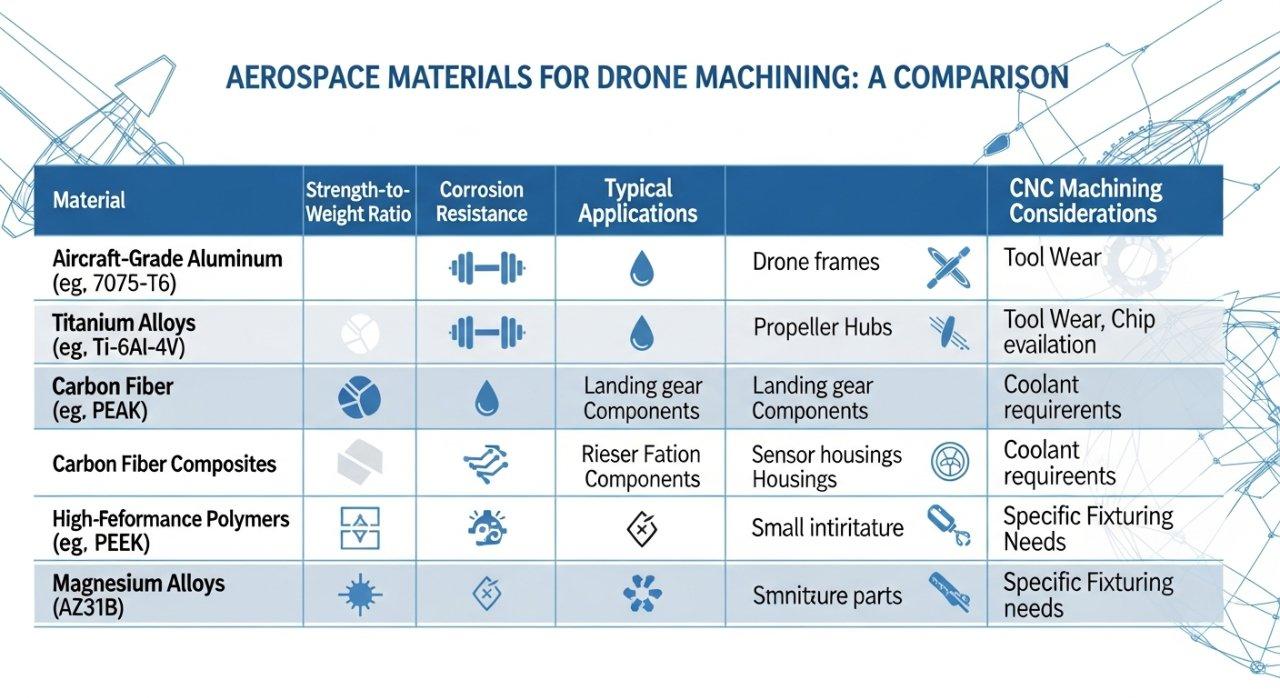

The journey to a high-quality drone part begins with meticulous material selection. For custom drone parts CNC, common choices include aerospace-grade aluminum alloys, titanium, and carbon fiber composites.

ly-machining ensures that all raw materials undergo stringent incoming quality inspection (IQC). This includes verification of material certifications (MTCs) and, when necessary, independent lab analysis to confirm chemical composition and mechanical properties.

Design for Manufacturability (DFM) in Precision Drone Machining

Effective DFM is a cornerstone of preventing quality issues before they arise. ly-machining collaborates closely with clients during the design phase to optimize drone component manufacturing.

Our engineering team provides detailed DFM reports, identifying potential challenges related to tolerances, material stress, or machining processes. This proactive approach minimizes rework and accelerates production timelines for custom drone parts CNC.

In-Process Monitoring for Consistent CNC Machining

Quality control is not merely an end-of-line activity; it’s integrated throughout the entire CNC machining process. Real-time monitoring is essential for maintaining consistency.

During production, ly-machining utilizes statistical process control (SPC) and in-situ probing to detect deviations immediately. This allows for prompt adjustments, preventing the production of non-conforming parts and upholding the highest standards in drone component manufacturing.

Advanced QC Techniques for Drone Parts Machining

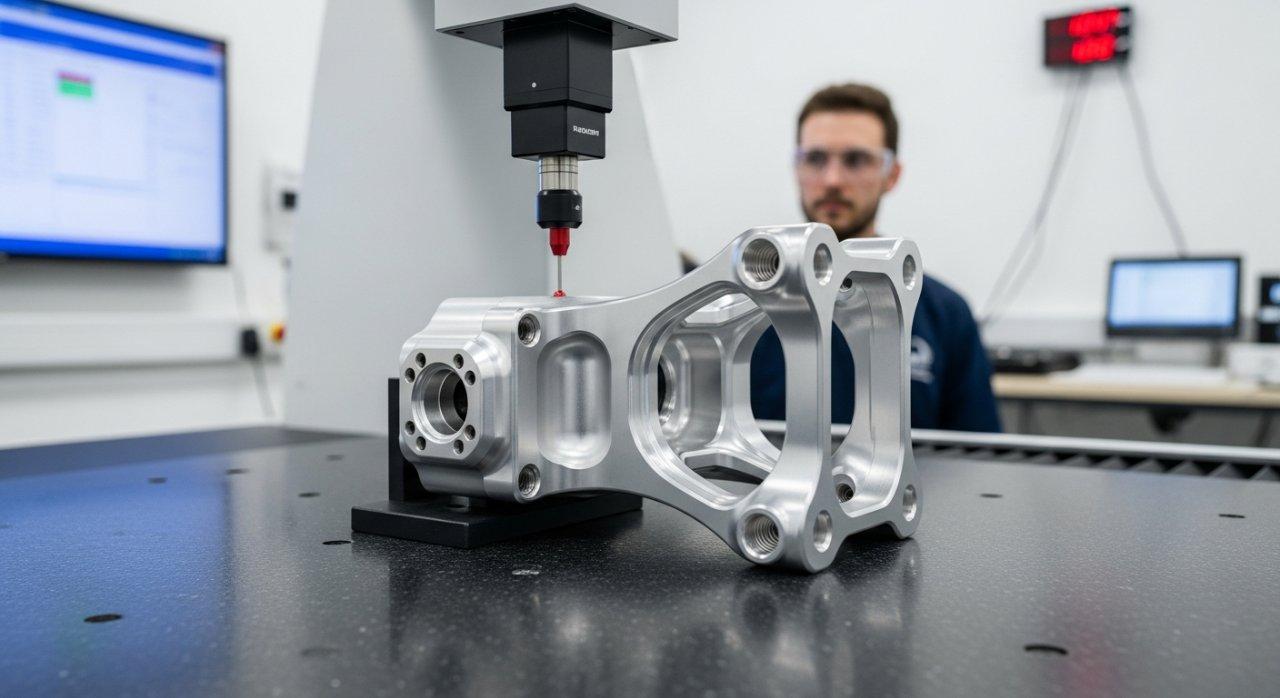

Metrology and Inspection for CNC Machined Drone Parts

Precision drone machining relies heavily on advanced metrology equipment to verify exact dimensions and geometries. Post-machining inspection is critical for certifying parts.

ly-machining employs a suite of high-precision tools, including CMMs (Coordinate Measuring Machines), optical comparators, and laser scanners. These instruments ensure that every CNC machined drone part meets specified geometric dimensioning and tolerancing (GD&T) requirements.

Non-Destructive Testing for Drone Component Manufacturing

For certain mission-critical drone parts, non-destructive testing (NDT) provides crucial insights into material integrity without causing damage. This is particularly vital for detecting subsurface flaws.

In our expertise, techniques such as penetrant testing, magnetic particle inspection, or eddy current testing are employed for custom drone parts CNC where material integrity is paramount. This ensures hidden defects are identified.

Surface Finish & Post-Processing for Custom Drone Parts CNC

The final surface finish and any post-processing treatments significantly impact a drone component’s performance and durability. Precision is required even in these final stages.

ly-machining offers various post-processing options, including anodizing, chemical conversion coating, and passivation, tailored to the specific application of the drone part. Strict quality checks ensure uniformity and adherence to aesthetic and functional specifications.

Our Factory’s QC Advantage in Drone CNC Machining

Source Manufacturer Edge: Quality in CNC Machining

As a source manufacturer, ly-machining exercises complete control over the entire production chain, from raw material sourcing to final inspection. This eliminates intermediaries and ensures unparalleled quality.

Our comprehensive, in-house capabilities for CNC machining of drone parts mean consistent processes and accountable results. This direct approach fosters trust and reliability for demanding projects.

Transparent Pricing for Custom Drone Parts CNC

ly-machining offers transparent, factory-direct pricing without hidden costs. Our clients benefit from direct communication and a clear understanding of the investment in their high-quality components.

This model not only provides cost-efficiency but also reinforces trust, allowing clients to make informed decisions for their custom drone parts CNC projects. We focus on delivering value through superior quality and efficiency.

Deep Technical Expertise in Precision Drone Machining

With years of hands-on experience in manufacturing complex components for demanding industries, ly-machining’s technical expertise is second to none. We excel at challenging projects involving tight tolerances and exotic materials.

Our team provides invaluable DFM insights, rapid prototyping (often within 24 hours), and sophisticated solutions for 5-axis machining. This ensures even the most complex drone designs are accurately realized.

Certifications for Drone Component Manufacturing

Adherence to international quality standards is non-negotiable for drone component manufacturing. ly-machining is proud to hold ISO9001 and IATF16949 certifications.

These certifications demonstrate our commitment to world-class quality management systems, providing clients with the confidence that their critical drone parts are produced under the most stringent controls.

Choosing a Partner for Drone Parts CNC Machining

Key Questions for Suppliers of Custom Drone Parts CNC

When selecting a manufacturing partner for custom drone parts CNC, inquire about their specific experience with aerospace-grade materials and complex geometries. Ask for examples of their quality documentation.

It is crucial to understand their quality control protocols, from material verification to final inspection. A reliable partner will offer full transparency and detailed answers regarding their processes.

| Aspect of Inquiry | Detail to Seek from Supplier |

|---|---|

| **Material Sourcing** | MTCs, traceability, vendor qualification |

| **Quality System** | Certifications (ISO9001, AS9100), audit results |

| **Machining Capability** | Machine types (5-axis), smallest feature size |

| **Inspection Tools** | CMM models, optical scanners, calibration records |

Value of Comprehensive Quality Control in CNC Machining

Investing in a manufacturing partner with comprehensive quality control minimizes risks and reduces total project costs in the long run. It prevents costly failures and rework.

This commitment to quality assurance ensures that every CNC machined part contributes positively to the drone’s overall performance and mission success, delivering peace of mind.

Elevate Drone Performance with Quality Parts

Partner for Precision Drone Machining Success

For drone manufacturers, partnering with a precision CNC machining expert is a strategic decision. It ensures that innovative designs are transformed into flawless, high-performance physical components.

ly-machining stands as your trusted partner, combining deep technical expertise, advanced quality control, and the efficiency of a source manufacturer. We are dedicated to the success of your drone component manufacturing projects.

| ly-machining Advantage | Client Benefit |

|---|---|

| **Source Manufacturer** | Direct control, transparent pricing |

| **DFM & 5-axis Expertise** | Complex designs realized, rapid prototyping |

| **ISO/IATF Certified QC** | Uncompromising reliability, risk mitigation |

| **Advanced Metrology** | Micron-level precision, verifiable quality |

Ready to elevate your drone’s performance with components built for absolute reliability? Contact our technical experts today for a transparent consultation and a custom quote that reflects ly-machining’s commitment to precision and your success.

Can ly-machining handle complex drone part geometries?

Absolutely. ly-machining specializes in complex structure processing, including advanced 5-axis CNC machining capabilities.

This allows us to produce intricate geometries and tight tolerances essential for modern drone designs. Our DFM expertise further ensures manufacturability.

How does ly-machining ensure material quality?

ly-machining implements rigorous incoming quality inspection (IQC) for all raw materials.

We verify material certifications (MTCs) and conduct independent lab analyses as needed, ensuring only the highest-grade materials are used for your drone components.

What certifications does ly-machining hold for quality?

ly-machining is proud to be ISO9001 and IATF16949 certified.

These global standards underscore our commitment to robust quality management systems and continuous improvement in all aspects of CNC machining.