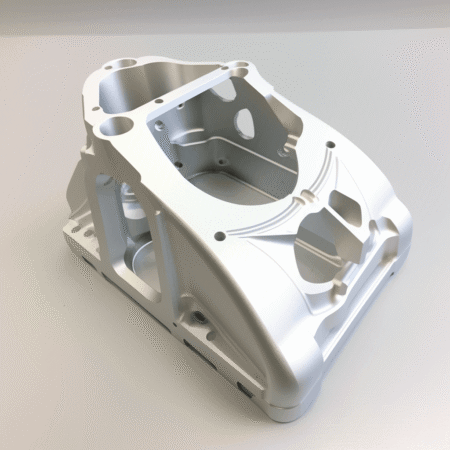

Rapid prototyping to volume CNC machining services

Machining Services

CNC milling

CNC turning

cnc 5 axis

Surface treatment

Bicycle enthusiasts and performance seekers alike know the importance of having reliable, high-quality parts for their bikes. Whether you’re looking to upgrade your current setup or build your dream machine from the ground up, bicycle modification parts made with CNC machining offer unmatched precision and durability. Ly-Machining specializes in producing custom CNC-machined bicycle parts designed to elevate your cycling experience and performance. In this article, we’ll dive into the benefits of CNC machining for bicycle modification and how these custom parts can take your bike to the next level.

What Makes CNC Machining the Best Choice for Bicycle Modification Parts?

When it comes to modifying your bike, the importance of precision and quality cannot be overstated. Traditional manufacturing methods often fall short in delivering the exact specifications and performance needed for cycling enthusiasts. CNC (Computer Numerical Control) machining, however, allows for highly accurate, repeatable production of parts, making it the go-to solution for custom bicycle components.

CNC machining works by using computer-controlled tools to shape materials with a high degree of accuracy. This technology ensures that every piece fits perfectly, resulting in optimal performance and longevity. Additionally, CNC machining allows for the production of parts from a variety of high-quality materials such as aluminum, titanium, and carbon fiber, which are essential for improving your bike’s strength, weight, and overall performance.

Key Benefits of CNC-Machined Bicycle Modification Parts

Precision and Accuracy CNC machining provides exact measurements and consistent quality, ensuring that every part is manufactured to the highest standards. This precision minimizes the risk of defects and ensures that the parts fit perfectly on your bike, contributing to enhanced performance and safety.

Customization Options One of the most significant advantages of CNC machining is its ability to produce custom designs. Whether you want to improve aerodynamics, enhance strength, or simply stand out with a unique look, CNC machining can accommodate all your specifications. Ly-Machining offers tailored solutions to meet your specific needs.

Durability and Strength CNC-machined parts are known for their superior durability. With the ability to use high-performance materials such as aluminum alloys and titanium, these parts withstand wear and tear, ensuring your bike performs optimally for years to come.

Lightweight Performance Achieving a balance between strength and weight is crucial for cycling. CNC machining allows for the precise removal of material to create lightweight parts that do not compromise on strength, contributing to faster, more agile cycling.

Transitioning to High-Performance Custom Parts

If you’re considering upgrading your bike with CNC-machined parts, the process is straightforward and highly rewarding. Start by identifying which components of your bike could benefit from modification—whether it’s the frame, wheels, handlebars, or smaller parts such as pedals and brake components.

At Ly-Machining, we offer a wide range of modification parts designed for various types of bicycles, including road bikes, mountain bikes, and performance bikes. With our state-of-the-art CNC machining process, you’ll get parts that fit perfectly, enhance your bike’s performance, and ensure a smooth, safe ride.

Why Choose Ly-Machining for Your Bicycle Modification Parts?

Ly-Machining has built a reputation for delivering top-tier CNC machining services for cycling enthusiasts. Our commitment to precision, high-quality materials, and customer satisfaction makes us the trusted choice for all your bike modification needs. By choosing Ly-Machining, you gain access to:

Advanced CNC Technology: We use the latest CNC machines for precise and efficient production.

Customization at Its Best: We can create parts tailored to your bike’s unique specifications.

Expert Craftsmanship: Our team of experienced engineers ensures that every part meets the highest standards of quality and durability.

Fast Turnaround Time: We understand that time is of the essence, and we strive to deliver your custom parts quickly without sacrificing quality.

Frequently Asked Questions (FAQs)

Q: What types of bicycle parts can be modified with CNC machining?

A: CNC machining can be used to modify a wide variety of bicycle parts, including frames, handlebars, pedals, gears, wheels, and more. Virtually any component that requires high precision and custom design can benefit from CNC machining.

Q: How does CNC machining improve the performance of my bike?

A: CNC machining ensures that your parts are made with extreme accuracy, reducing any potential weaknesses or imperfections. This leads to better-fitting parts that contribute to smoother rides, improved aerodynamics, and better durability. Custom modifications can also be made to optimize weight distribution and strength, improving overall performance.

Q: Are CNC-machined bicycle parts more expensive than standard parts?

A: While CNC-machined parts may have a higher upfront cost due to the custom nature of the process, they often provide long-term value through increased durability and performance. Additionally, the precise fit reduces the likelihood of needing replacements or repairs, making them a worthwhile investment for serious cyclists.

Q: How long does it take to get custom CNC-machined parts for my bicycle?

A: The time required for CNC machining depends on the complexity of the part and the specifications involved. At Ly-Machining, we aim to provide fast turnaround times without compromising quality, so you can enjoy your upgraded bike as soon as possible.

Q: Can CNC machining help with both aesthetics and performance?

A: Yes! CNC machining not only offers functional improvements but also allows for unique aesthetic modifications. Whether you’re looking to enhance the look of your bike with custom designs or make performance-based adjustments, CNC machining can meet both needs.

Related products

- Aluminum

Aluminum CNC machining parts