Nylon parts are commonly used across various industries due to their durability, flexibility, and wear resistance. At LY-Machining, we specialize in the CNC turning and milling machining of high-quality nylon parts. Our advanced machining techniques ensure precision and reliability, making us the preferred partner for businesses requiring top-tier nylon components.

Why Choose Nylon for CNC Machining

Nylon, a versatile thermoplastic material, offers a variety of benefits for machining. Its lightweight nature, combined with excellent mechanical properties, makes it ideal for applications requiring strength, wear resistance, and low friction.

Durability: Nylon is known for its high impact strength, which ensures parts last longer and perform reliably.

Wear Resistance: The material resists abrasion and friction, making it suitable for moving parts in machinery and equipment.

Lightweight: With its low density, nylon parts help reduce overall weight in products without compromising strength or functionality.

CNC Turning and Milling for Nylon Parts

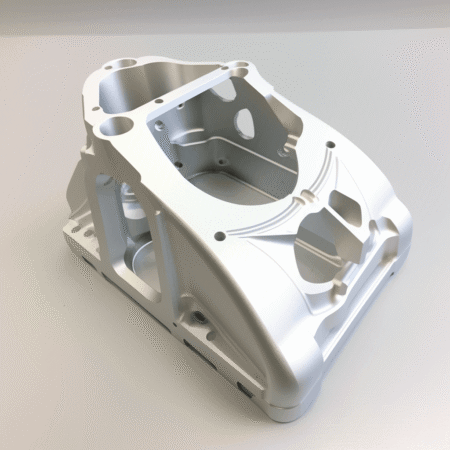

At LY-Machining, we utilize state-of-the-art CNC turning and milling machines to produce nylon parts with exceptional precision. Our technology allows us to work with intricate designs and complex geometries, ensuring that each part meets stringent specifications.

CNC Turning: This process is perfect for producing cylindrical nylon parts such as shafts, bearings, and bushings. It ensures smooth surfaces and exact tolerances.

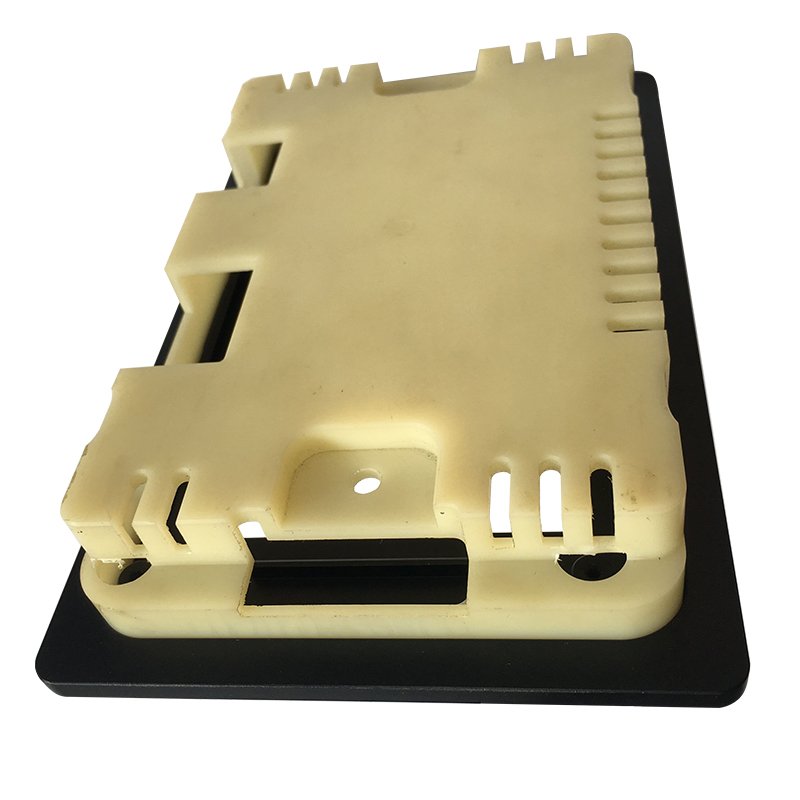

CNC Milling: Our milling process enables the creation of detailed nylon components with a wide range of shapes and sizes. Whether it’s drilling, slotting, or cutting, CNC milling provides the flexibility to meet various design needs.

Key Benefits of CNC Machining for Nylon Parts

CNC machining is the preferred method for producing nylon parts due to its precision, efficiency, and ability to handle complex designs. Here are some key benefits of CNC machining for nylon:

High Precision: Our CNC machines offer unparalleled precision, ensuring that every nylon part is made to exact specifications.

Complex Geometries: CNC machining is ideal for producing nylon parts with intricate shapes, such as custom fittings, gears, or housings.

Consistent Quality: With automated processes, we guarantee uniformity across all parts, reducing the likelihood of defects and ensuring high-quality production.

Industries That Benefit from Nylon Parts

Nylon is widely used in several industries due to its strength, flexibility, and resistance to wear. Some of the main industries that rely on nylon parts include:

Automotive: Nylon is commonly used in the automotive industry for components like gears, bearings, and fuel system parts due to its ability to withstand harsh conditions.

Electronics: Nylon’s electrical insulating properties make it a popular choice for components such as connectors, switches, and housings.

Industrial: In manufacturing, nylon is used for a wide range of parts, from rollers and pulleys to bushings and bearings, providing both performance and durability.

Consumer Goods: Nylon parts are also found in everyday items, such as toothbrush heads, power tool components, and kitchen equipment, due to their reliability and versatility.

Why LY-Machining is Your Trusted Partner for Nylon CNC Machining

When you partner with LY-Machining, you can expect the highest quality nylon parts, delivered on time and at competitive prices. Here’s why we are the right choice for your nylon machining needs:

Expertise in Nylon Machining: Our team has extensive experience in CNC machining for nylon, ensuring that we can handle even the most complex parts with ease.

Advanced CNC Technology: We invest in the latest CNC turning and milling equipment to provide precise and consistent results on every part.

Timely Delivery: We understand the importance of deadlines and ensure quick turnaround times for both small and large-scale production runs.

Cost-effective Solutions: We offer competitive pricing, helping you get high-quality nylon parts without exceeding your budget.

Frequently Asked Questions

Q: What are the benefits of using nylon in CNC machining?

Nylon is durable, wear-resistant, lightweight, and offers excellent mechanical properties, making it ideal for a wide range of applications in various industries.

Q: How accurate is CNC machining for nylon parts?

CNC machining provides high precision, ensuring that nylon parts are produced to exact tolerances and meet design specifications consistently.

Q: What types of parts can be made from nylon?

Nylon can be used to create a variety of parts, including bearings, gears, bushings, shafts, and custom components for industries such as automotive, electronics, and manufacturing.

Q: How long does it take to produce nylon parts using CNC machining?

The time it takes to machine nylon parts depends on the complexity and quantity of the parts. At LY-Machining, we prioritize fast turnaround times without compromising on quality.

Get High-Quality Nylon Parts Today

If you’re looking for precise, durable, and cost-effective nylon parts, LY-Machining is here to help. Our CNC turning and milling services are tailored to meet your exact needs, ensuring that you receive top-quality parts for your project. Contact us today to learn more about how we can support your nylon part production needs!