Rapid prototyping to volume CNC machining services

Machining Services

CNC milling

CNC turning

cnc 5 axis

Surface treatment

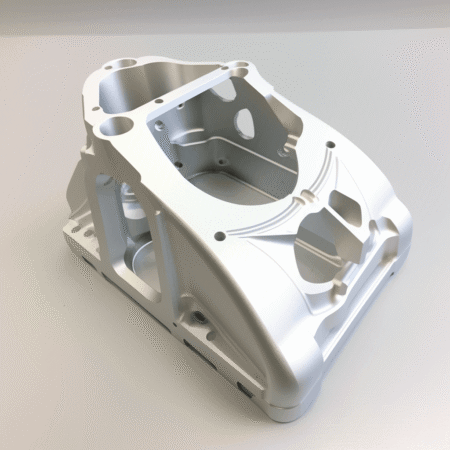

At LY-Machining, we pride ourselves on delivering high-precision CNC machining services for the most demanding and critical applications. This case study highlights our successful partnership with a leading developer of advanced optical testing instruments, providing them with essential structural components that meet stringent requirements for stability, accuracy, and durability. Our unwavering commitment to quality control, efficient production workflows, and reliable on-time delivery underpins client success.

The Client’s Critical Need: Stable Optical Frameworks

Our client, an innovator in the field of sophisticated optical testing instruments, faced a significant challenge: sourcing structural parts that offered exceptional dimensional stability, intricate feature accuracy, and robust mechanical integrity. These components form the backbone of their precision instruments, directly impacting measurement accuracy and long-term reliability.

Their primary concerns revolved around:

- Structural Integrity and Stability: The optical instrument structural parts needed to provide a rock-solid foundation, free from vibration or deformation, critical for precise optical alignment.

- Dimensional Precision and Repeatability: Extremely tight tolerances were required to ensure the accurate positioning of optical elements and sensor arrays.

- Surface Finish and Material Purity: The components needed to be free from defects that could affect optical paths or instrument longevity.

- Timely Project Completion: Delays in component delivery could significantly impact their instrument assembly schedules and market launch.

- Cost Efficiency: Balancing the need for ultra-high quality with a competitive cost structure was essential for their overall project viability.

Our Comprehensive Solution: Advanced CNC Machining for Optics

We approached this project with a strategic, all-encompassing plan, leveraging our advanced CNC machining capabilities and the deep expertise of our engineering team. Our objective was to not only meet but unequivocally surpass the client’s exacting expectations for their optical testing instrument components.

Meticulous Process Control for CNC Accuracy

Our solution began with an in-depth process control methodology. We developed a highly detailed manufacturing plan, from initial CAD/CAM programming and material selection to rigorous final inspection protocols. This meticulous approach ensures that every single stage contributes positively to the overall quality and performance of the CNC machined structural part.

Rigorous Quality Assurance in CNC Production

Quality is of paramount importance in the fabrication of optical instrument components. We implemented a multi-faceted quality control system that includes continuous in-process measurements and comprehensive final dimensional verification using advanced metrology equipment. This guarantees the precision machining and integrity of each structural component.

Reliable Delivery and Proactive Project Management

Understanding the client’s critical need for prompt delivery, we established clear and achievable production timelines. Our dedicated project management team closely monitored every phase of the project, ensuring all deadlines for these custom machined parts were consistently met without any compromise on quality.

Optimized Cost-Effectiveness Through Manufacturing Expertise

By continuously optimizing our CNC machining processes, minimizing material waste, and leveraging efficient production techniques, we delivered a highly cost-effective solution. This enabled the client to maintain their budget while still receiving superior precision machined components for their optical instruments.

Achieving Excellence: Tangible Outcomes

Our collaborative partnership resulted in the successful production and delivery of numerous optical testing instrument structural parts, consistently meeting and often exceeding the client’s rigorous specifications.

Unwavering Structural Integrity and Flawless Finish

The CNC machined structural parts exhibited exceptional rigidity and stability, along with an impeccable surface finish, free from any defects. This provided the essential robust framework required for the client’s high-precision optical instruments.

Uncompromising Precision and Adherence to Tight Tolerances

Every single structural component underwent and passed stringent quality checks. We consistently maintained ultra-tight tolerances, which were absolutely critical for the accurate assembly and optical performance of their testing devices. This powerfully demonstrated our commitment to precision CNC machining in optical applications.

Consistent On-Time Delivery, Every Time

We achieved a 100% on-time delivery record, ensuring the client’s instrument assembly line operated seamlessly and without interruption. Our efficiency in CNC manufacturing directly contributed to preventing costly project delays.

Exceptional Value and High Client Satisfaction

The client expressed profound satisfaction with both the exceptional quality of the CNC machined parts and the comprehensive value we provided. Our efficient processes were instrumental in the success and timely completion of their instrument development project.

Client Endorsement

“LY-Machining proved to be an indispensable partner for our optical testing instrument structural components. Their precision CNC machining capabilities, coupled with their unwavering dedication to quality control and reliable on-time delivery, truly set them apart. The structural parts they produced were flawless, meticulously meeting our extremely tight specifications for stability and accuracy. We wholeheartedly recommend their CNC services for any demanding precision machining needs in the optical industry.”

Why Choose LY-Machining for Your Precision CNC Needs?

When your project demands precision CNC machining, LY-Machining offers unparalleled expertise and unwavering reliability. We are your ideal partner for custom CNC parts, whether for optical instruments, scientific equipment, aerospace components, or complex medical devices.

Profound Expertise in Precision Metal Machining

We excel in machining a wide range of metals, including aluminum, stainless steel, and other alloys, perfectly suited for optical instrument structural parts. Our extensive capabilities ensure we can meet diverse project requirements for CNC components with optimal material selection.

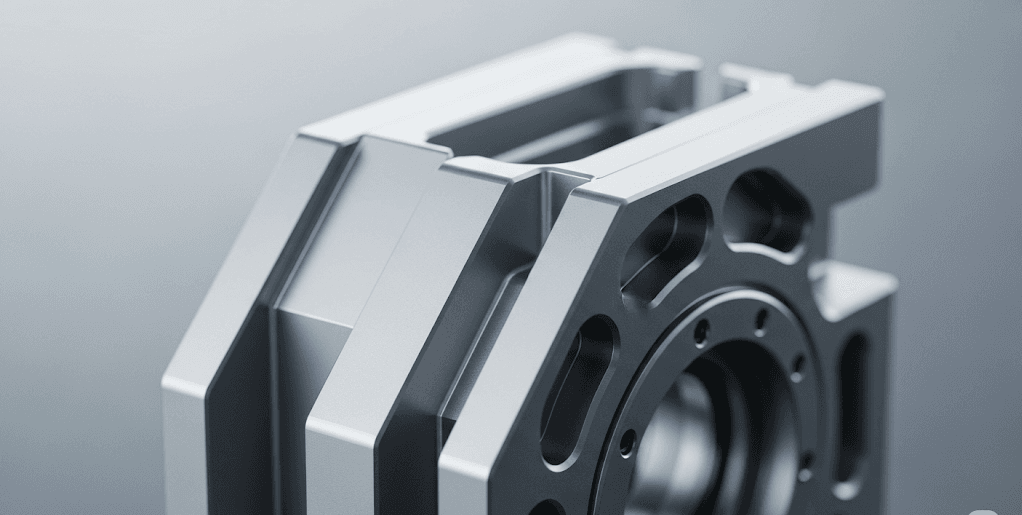

State-of-the-Art CNC Machining Facilities

Our facility is equipped with cutting-edge multi-axis CNC machines, including 5-axis capabilities. This empowers us to expertly handle highly complex geometries and consistently achieve superior machining accuracy for all precision parts, ensuring critical flatness and parallelism.

Dedicated Quality Assurance in CNC Manufacturing

Our comprehensive quality management system ensures that every single CNC machined part leaving our facility strictly adheres to the highest industry standards. We firmly believe in proactive quality control throughout the entire manufacturing process, from raw material inspection to final dimensional verification using CMM.

Streamlined Project Management for Custom Components

From the initial consultation and design review to the final delivery, our experienced project managers ensure seamless communication and highly efficient execution. We strive to make the CNC machining process exceptionally smooth and completely transparent for our clients, providing regular updates.

Commitment to Continuous Innovation in Precision Machining

We consistently invest in pioneering technologies, advanced tooling, and ongoing training for our skilled machinists to remain at the forefront of CNC machining advancements. This enables us to offer innovative solutions and maintain our competitive edge in precision manufacturing for critical applications.

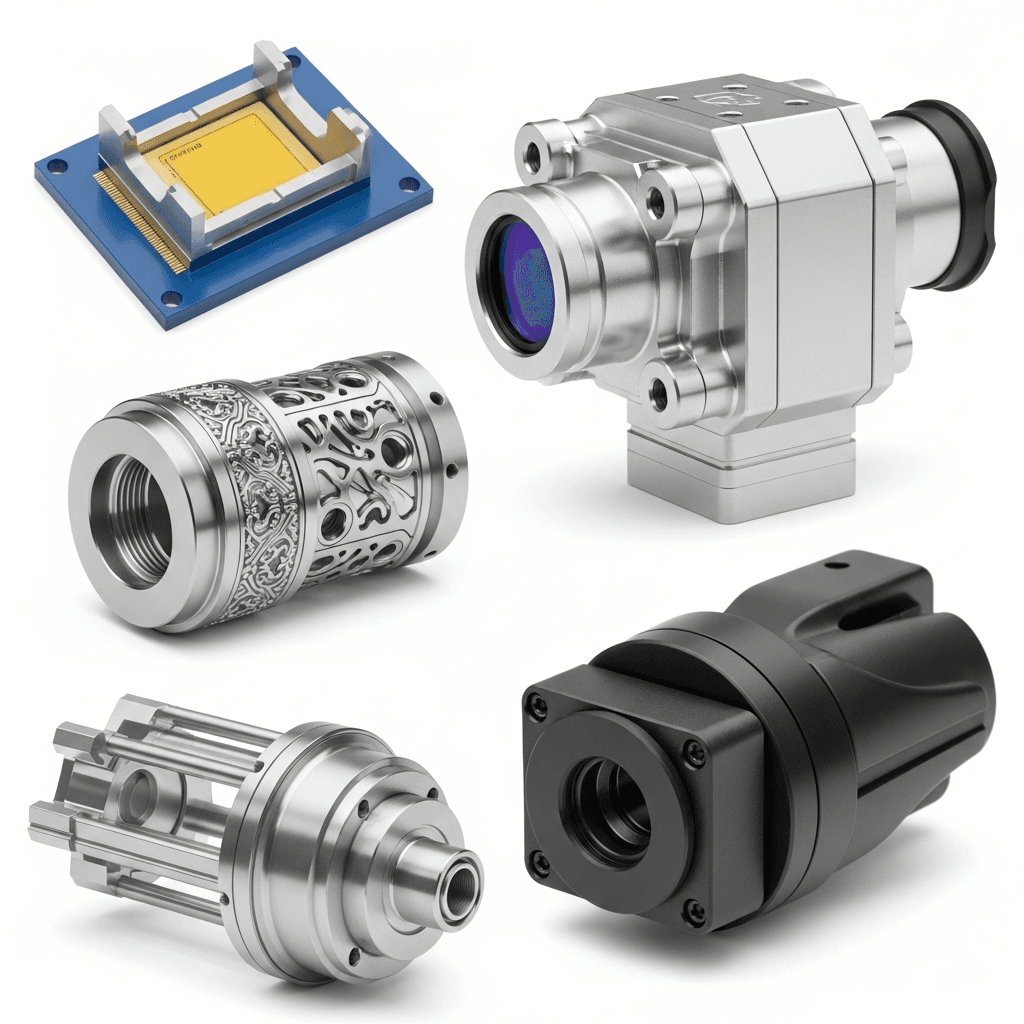

Beyond Structural Parts: Our Extensive CNC Machining Capabilities

While this case study focuses specifically on optical testing instrument structural components, our expertise spans a wide and diverse range of CNC machining applications.

Custom Component Manufacturing for Diverse High-Tech Industries

We regularly produce highly custom components for the semiconductor, defense, medical imaging, and robotics industries, among others. Each project benefits from our meticulous attention to detail and unparalleled precision engineering.

From Rapid Prototyping to High-Volume Production Runs

Whether you require a single rapid prototype part for design validation or thousands of production components for scaled manufacturing, we seamlessly scale our operations to precisely meet your volume requirements. Our flexible approach provides comprehensive support for your project from its early development to mass production.

Advanced Surface Finishing and Post-Machining Processes

Beyond the core machining process, we offer an array of advanced surface finishing options, including precision anodizing, blackening, electroless nickel plating, and specialized polishing. These processes significantly enhance both the functional performance (e.g., corrosion resistance, light absorption) and the aesthetic appeal of your CNC machined parts.

Handling Complex Geometries and Achieving Ultra-Tight Tolerances

Our highly skilled machinists, combined with our cutting-edge equipment, are exceptionally adept at handling complex geometries, thin walls, and consistently achieving ultra-tight tolerances (e.g., to microns). This capability is absolutely crucial for high-performance applications where extreme precision and repeatability are paramount.

Partner with LY-Machining for Your Next Precision Project

If you are actively seeking a reliable and expert partner for precision CNC machining of critical components, look no further than LY-Machining. We are passionately dedicated to providing high-quality, cost-effective, and timely solutions for your most intricate and challenging manufacturing needs.

Contact us today to discuss your next CNC machining project and experience the LY-Machining difference firsthand!

We are resolutely committed to delivering unrivaled precision, exceptional quality, and steadfast reliability in every single CNC machined component we produce.

Related products

- Aluminum

Tobacco grinder aluminum machining

- Aluminum

Aluminum CNC Turning Parts

- Aluminum

Aluminum CNC machining parts