Struggling to specify the right surface finish on your CNC machining drawings? Misinterpreting Ra and Rz values can lead to costly errors, project delays, and parts that fail quality checks, ultimately impacting your bottom line. You need a clear, reliable way to define and verify surface texture to ensure your components function as intended.

This guide deciphers the complexities of Ra and Rz, empowering you to make informed decisions for your CNC milling projects. By understanding these critical parameters, you can confidently choose the appropriate surface finish, communicate effectively with your manufacturing partner, and receive parts that meet your exact specifications. At ly-machining, we prioritize precision from drawing to delivery.

Understanding surface roughness is crucial for ensuring the quality and functionality of CNC machined parts. While there are many parameters, Ra and Rz are two of the most frequently specified on engineering drawings. Therefore, knowing the distinction between them is essential for designers, engineers, and anyone involved in the CNC milling process. This knowledge not only ensures clear communication but also helps in achieving the desired performance and longevity of the final product. Consequently, a deeper dive into these parameters will clarify how they impact your project’s success.

Understanding Ra: The Arithmetic Average

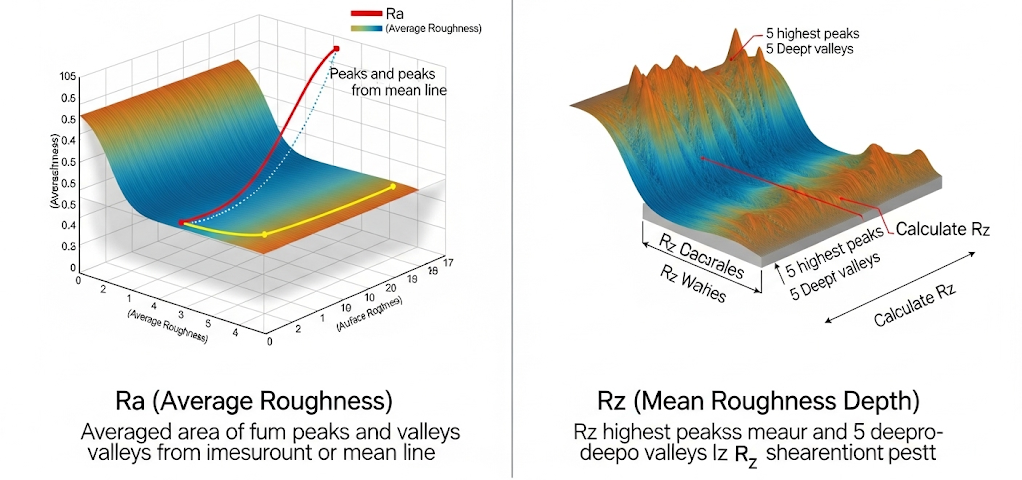

Ra, or Roughness Average, is the most widely used surface roughness parameter globally. It represents the arithmetic average of the absolute values of the profile deviations from the mean line within the evaluation length. Think of it as a general overview of the surface texture.

Because it calculates an average, Ra provides a stable and repeatable measurement. This makes it an excellent general-purpose indicator for many CNC machining applications. It effectively controls the overall texture, ensuring consistency across production runs. However, it can sometimes mask individual high peaks or deep valleys that might be critical for specific functions.

For most standard CNC milling projects, specifying an Ra value is sufficient to achieve the desired surface quality. It’s a straightforward parameter that manufacturing partners like ly-machining understand well, ensuring your requirements are met without ambiguity.

Decoding Rz: The Ten-Point Mean Roughness

Rz offers a more detailed assessment of surface roughness. It is calculated by averaging the height of the five highest peaks and the depth of the five deepest valleys over the evaluation length. This method provides a more sensitive measure of surface irregularities.

Unlike Ra, Rz is particularly effective at identifying isolated surface defects such as deep scratches or high burrs that could compromise a part’s function, especially in sealing or bearing applications. When your component requires a flawless surface for optimal performance, specifying an Rz value is often the better choice.

Choosing Rz in your CNC machining drawings signals that extreme peaks and valleys are a primary concern. This tells your manufacturing partner to pay closer attention to finishing processes to eliminate any potential outliers that the Ra measurement might miss.

Ra vs. Rz: A Practical Comparison

The primary distinction between Ra and Rz lies in what they measure. Ra provides a general, averaged smoothness, while Rz focuses on the extremes—the highest peaks and lowest valleys. This difference is critical when selecting the right parameter for your CNC milling project.

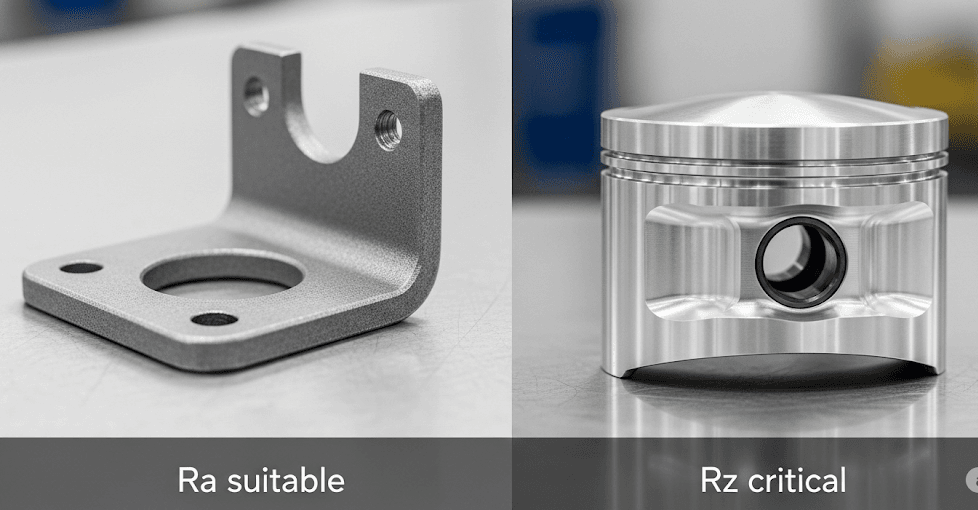

Consider the application of your part. If it’s a non-critical component where general smoothness is adequate, Ra is typically the go-to choice for its simplicity and reliability. It communicates the general expectation for the surface quality effectively.

However, if the part is used for a high-performance application, such as a hydraulic seal or a precision bearing surface, Rz becomes much more relevant. Here, a single deep scratch (a valley) could cause a leak or premature failure. Rz ensures these critical defects are controlled.

To help you decide, we’ve created a simple comparison:

| Parameter | Measures | Best For | CNC Machining Implication |

| Ra | Arithmetic average of profile deviations | General purpose applications, overall texture control | Standard finishing processes, consistent results |

| Rz | Average of the 5 highest peaks and 5 deepest valleys | High-performance parts, detecting isolated defects | Requires more meticulous finishing and inspection |

Using the correct parameter on your CNC drawings from the start prevents miscommunication and ensures the functional requirements of your parts are met precisely. At ly-machining, our experts can help you select the most appropriate callout for your specific needs.

How Surface Finish Affects Your CNC Project

The choice of surface finish directly impacts the manufacturing process, cost, and lead time of your CNC machining project. A finer finish, indicated by a lower Ra or Rz value, requires more processing steps, such as additional finishing passes, grinding, or polishing.

These extra steps naturally increase the machining time and, therefore, the overall cost. For this reason, it is crucial to avoid over-specifying the surface roughness. Specify only what is functionally necessary for your part’s application. Our team at ly-machining often collaborates with clients to find the perfect balance between performance and cost-effectiveness.

Furthermore, achieving a very fine surface finish might influence the choice of material and tooling. Some materials are inherently more difficult to machine to a smooth finish. By discussing your CNC milling requirements with us early on, we can provide guidance on material selection and design for manufacturability (DFM) to optimize the outcome.

Frequently Asked Questions

1. Can I convert Ra to Rz? While some conversion charts and formulas exist, they are only approximations. The relationship between Ra and Rz is not linear and depends heavily on the machining process and material. For critical applications, it is always best to specify the exact parameter (either Ra or Rz) required rather than relying on a conversion.

2. What is a standard surface finish for CNC machining? A common “as-milled” surface finish achieved through CNC milling is typically around Ra 3.2 μm (125 μin). For general-purpose parts, an Ra of 1.6 μm (63 μin) is often specified. Finer finishes below Ra 0.8 μm (32 μin) usually require secondary processes like grinding or lapping.

3. How does ly-machining ensure the specified surface finish is met? At ly-machining, we use calibrated surface profilometers to measure and verify the roughness of every part against the specifications on your CNC drawing. Our quality control process ensures that whether you specify Ra or Rz, your components will meet the required standard before they are shipped.