Rapid Prototyping CNC: 5 Key Benefits

Rapid prototyping CNC machining offers critical advantages, including accelerated product launch, unmatched precision, and cost-effectiveness for custom CNC prototyping and prototype machining services.

In today’s relentless product development landscape, is the pace of your innovation being held back by slow, costly prototyping? Imagine a process that accelerates your time-to-market, drastically cuts iteration expenses, and delivers flawless precision on demand. Welcome to the world of rapid prototyping CNC machining – a game-changer you can’t afford to overlook.

As a source manufacturer, we understand the immense pressure to innovate faster while maintaining uncompromised quality and managing budgets. This comprehensive guide reveals how computer numerical control services provide a definitive solution.

We will explore the five core advantages that empower engineers and product designers to bring their most ambitious visions to life with unmatched speed and accuracy.

Why Rapid Prototyping?

The Accelerating Pace of Product Development

In our experience, the demand for quicker product cycles has never been higher. Markets are evolving at an unprecedented rate, pushing R&D engineers and product designers to validate concepts and designs with extreme agility.

Delayed product launches can lead to significant competitive disadvantages and lost revenue opportunities. The ability to react swiftly to market feedback is now a core requirement for success.

This intense pressure makes the traditional, slow-paced development cycles unsustainable for modern product innovation.

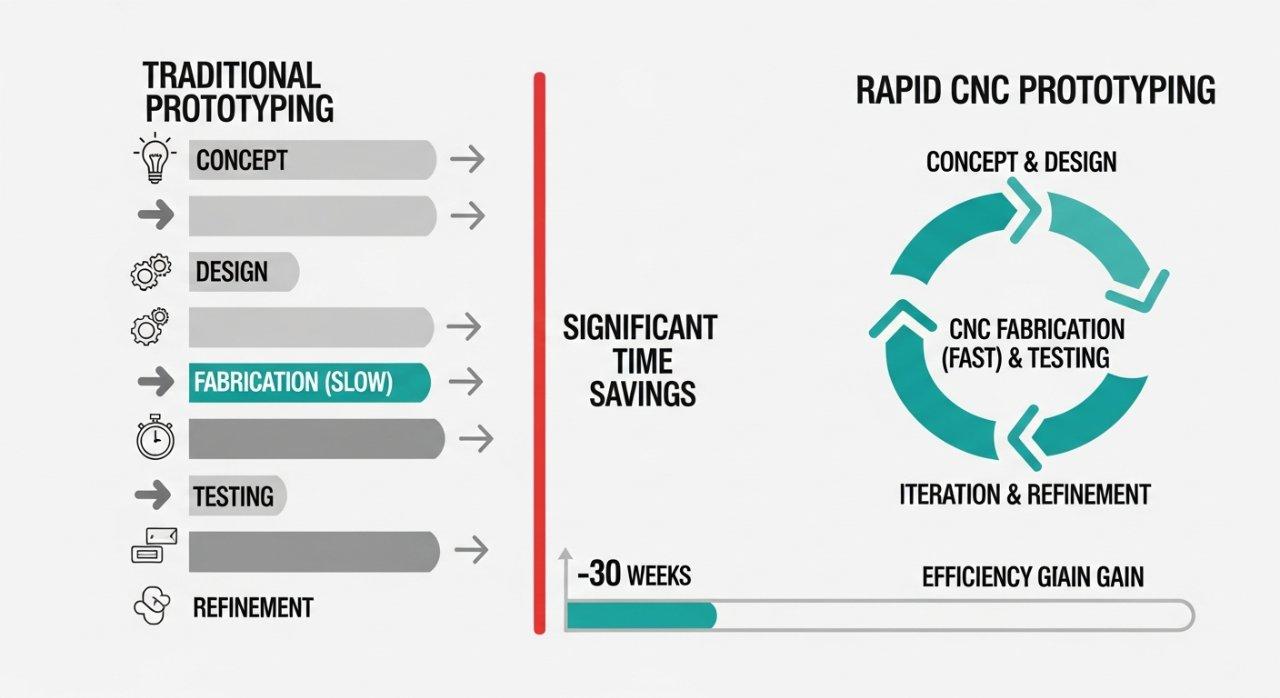

Overcoming Traditional Prototyping Bottlenecks

Traditional prototyping methods often involve lengthy lead times, especially when relying on manual processes or outsourced, non-specialized services. High tooling costs for injection molding, even for initial prototypes, present a major barrier.

A common issue we see is the inability to achieve the exact material properties and surface finishes needed for realistic functional testing. This often leads to compromises in validation.

These bottlenecks create significant delays and inflate overall development costs, hindering innovation.

The Strategic Imperative of Rapid CNC

Rapid prototyping CNC machining is no longer just a convenience; it’s a strategic imperative. It directly addresses these pain points by offering a method that is both fast and incredibly precise.

For project managers and procurement teams, this means better control over timelines and budgets. For engineers, it offers the freedom to iterate designs with confidence.

Embracing `rapid prototyping CNC` provides a critical competitive edge, ensuring products meet market demands faster and more reliably.

Accelerate Product Launch with Rapid CNC

Drastically Reduced Lead Times

One of the most compelling advantages of `CNC rapid prototyping` is the dramatic reduction in lead times. Unlike methods requiring extensive tooling, CNC machining can begin directly from a CAD file.

This direct manufacturing approach bypasses lengthy mold fabrication stages, allowing for parts to be produced in days, not weeks or months. Such speed is crucial for meeting aggressive project deadlines.

In our factory, optimized workflows and advanced machinery ensure quick turnaround times, getting prototypes into your hands faster.

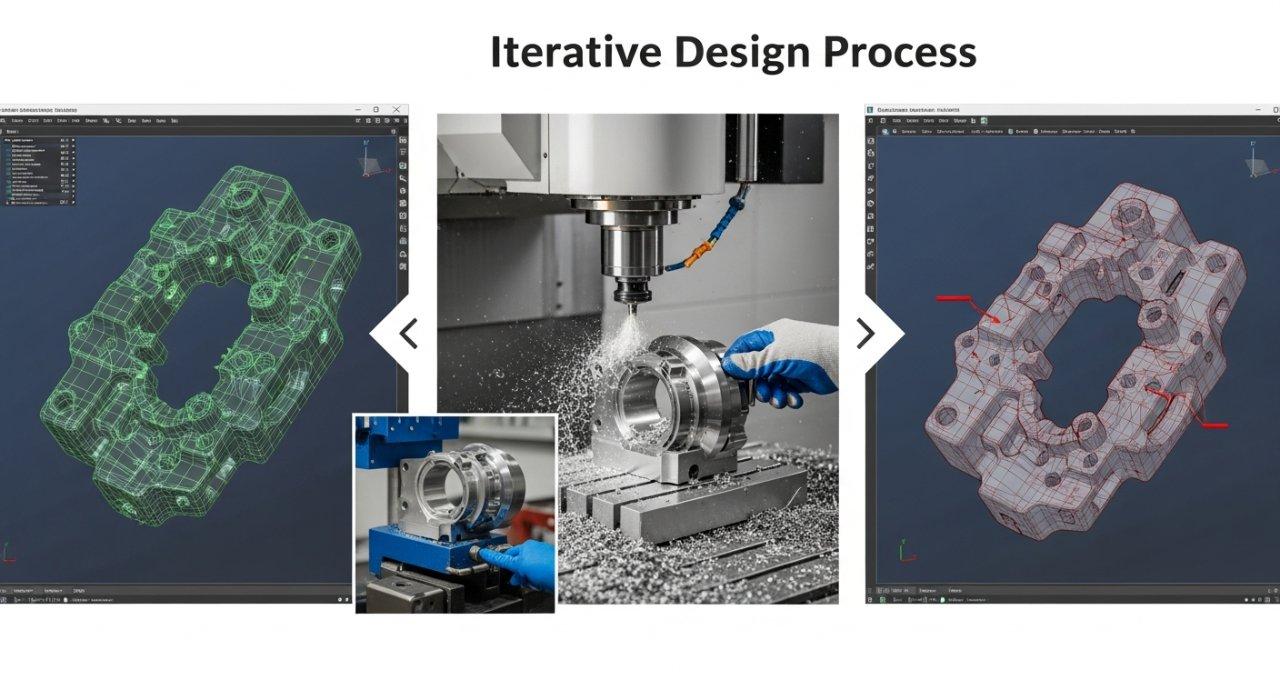

Streamlining Design Iteration Cycles

The ability to quickly produce physical prototypes enables engineers to test design concepts, gather immediate feedback, and implement refinements without significant delays. This creates an agile development loop.

Multiple design iterations can be executed within a fraction of the time required by traditional methods. This iterative process is vital for identifying and correcting design flaws early.

Accelerated iteration cycles mean design teams can explore more options, leading to more robust and optimized final products.

Gaining a Critical Market Advantage

Bringing a product to market quickly is often the difference between success and missed opportunities. `Rapid prototyping CNC` directly contributes to a first-mover advantage.

By validating designs faster, companies can shorten their overall time-to-market, beating competitors to launch. This can secure vital market share and establish brand leadership.

Our `prototype machining services` empower businesses to respond to trends and customer needs with unprecedented speed.

Unmatched Precision in CNC Prototyping

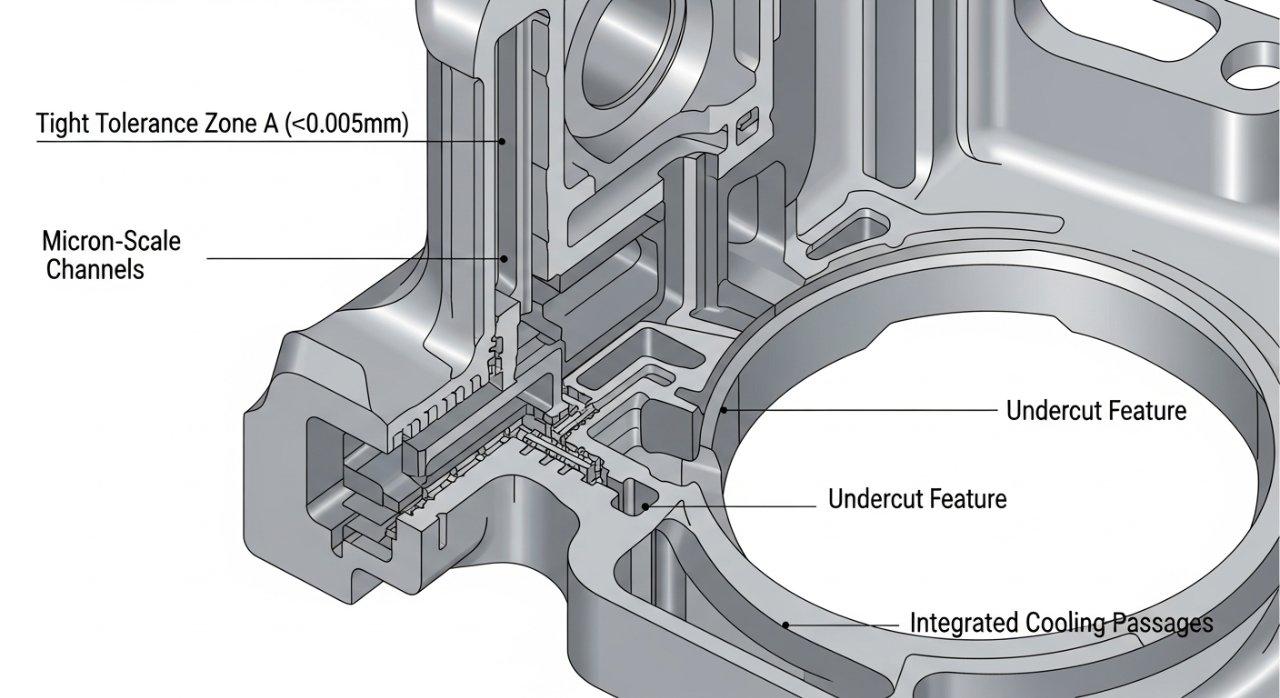

Achieving Strict Tolerances and Complex Geometries

Modern `CNC rapid prototyping` machines are capable of exceptionally high precision, routinely achieving tight tolerances down to 0.001 inches (0.025 mm) or less. This level of accuracy is essential for functional components.

Complex geometries, intricate internal features, and precise surface contours that are difficult or impossible with other methods are readily achievable. Multi-axis machining allows for highly detailed and accurate parts.

Table 1: Typical CNC Prototyping Tolerances (General)

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | +/- 0.005 inches | +/- 0.002 inches |

| Holes & Bores | +/- 0.003 inches | +/- 0.001 inches |

| Flatness | 0.005 inches / inch | 0.002 inches / inch |

Ensuring Functional Accuracy for Testing

Precision directly translates to functional accuracy. Prototypes machined with high precision will behave in testing exactly as the final production part is intended, providing reliable data.

This reliability is crucial for engineering validation, ensuring that performance tests accurately reflect product capabilities. It helps prevent costly design changes later in the product lifecycle.

When the prototype matches the design intent precisely, engineers can trust their test results.

Advanced CNC Technology for Superior Results

At ‘ly-machining’, we invest in state-of-the-art CNC machinery, including multi-axis milling and turning centers. These machines are integrated with sophisticated CAD/CAM software.

This combination allows for highly optimized tool paths and precise material removal, resulting in superior surface finishes and dimensional accuracy. Our skilled engineers oversee every detail.

Such advanced `computer numerical control services` ensure that every prototype meets the most stringent quality requirements.

Cost-Effective Rapid Prototyping

Reducing Upfront Tooling and Setup Costs

One of the significant financial burdens of traditional manufacturing is the high upfront cost of tooling, such as molds for injection molding. `Custom CNC prototyping` largely eliminates this expense.

CNC machining directly subtracts material from a raw block, requiring minimal setup and no dedicated tooling. This makes it incredibly cost-effective for low-volume production and one-off prototypes.

This reduction in initial investment allows companies to allocate resources more efficiently, focusing on innovation rather than fixed costs.

Minimizing Rework and Design Flaws

By enabling rapid iteration and early functional testing, `rapid prototyping CNC` helps identify design flaws and performance issues at an early stage. Addressing these problems early is always less expensive.

Correcting errors in the prototype phase is significantly cheaper than redesigning after tooling has been created or, worse, after mass production has begun. It mitigates the risk of costly recalls.

This proactive approach minimizes rework, saving both time and substantial financial resources throughout the development cycle.

Transparent Pricing for Optimal Value

As a source manufacturer, ‘ly-machining’ is committed to transparent pricing for all `prototype machining services`. We provide clear quotes with no hidden fees, allowing for accurate budget planning.

Our efficient processes and direct manufacturing capabilities translate into competitive pricing for high-quality parts. We focus on delivering maximum value.

This transparency and efficiency ensure you receive optimal value for your investment in precision prototyping.

Design Freedom via CNC Machining

Exploring Diverse Materials and Finishes

`CNC rapid prototyping` offers unparalleled versatility in material selection. Designers are not limited by the availability of molds or specific manufacturing processes.

We can work with a wide array of engineering-grade plastics and metals, including aluminum, stainless steel, brass, ABS, Nylon, Polycarbonate, and PEEK. This allows for realistic material testing.

Additionally, various surface finishes, such as polished, bead-blasted, anodized, or painted, can be applied to mimic the final product’s aesthetic and functional properties.

Table 2: Common Materials for CNC Rapid Prototyping

| Material Type | Examples | Key Characteristics |

|---|---|---|

| Metals | Aluminum, Stainless | High strength, thermal stability, machinability |

| Plastics | ABS, Nylon, Polycarb | Lightweight, electrical insulation, impact resist. |

| Engineering Resins | PEEK, Delrin | High performance, wear resistance, chemical resist. |

Bringing Complex Visions to Life

The subtractive nature of CNC machining allows for the creation of incredibly complex geometries, intricate features, and fine details. Designs that might be challenging for additive manufacturing or impossible for molding are often achievable.

Engineers have the freedom to push the boundaries of their designs, knowing that their complex visions can be accurately translated into a physical prototype. This fosters greater innovation.

It supports the exploration of advanced ergonomic, aesthetic, and functional considerations without manufacturing limitations.

Expert Technical Guidance for Manufacturability

Our team of experienced engineers provides invaluable technical guidance, offering design for manufacturability (DFM) insights. We ensure that your complex designs are not only prototyped but also optimized for future mass production.

This collaborative approach helps anticipate and resolve potential manufacturing challenges early in the design phase. It ensures efficiency and cost-effectiveness.

We partner with you to turn ambitious concepts into manufacturable realities.

Rapid Prototype Validation & Iteration

Early Performance Testing and Feedback Loops

`Rapid prototyping CNC` facilitates the creation of fully functional prototypes that can undergo rigorous performance testing under real-world conditions. This provides critical data and feedback.

These early tests allow engineers to evaluate functionality, ergonomics, assembly, and user experience. Any issues can be quickly identified and addressed.

The rapid turnaround of prototypes supports a continuous feedback loop, where insights from testing directly inform the next design iteration.

Reducing Risks Before Mass Production

Thorough validation during the prototyping phase is crucial for mitigating risks. By identifying and resolving potential design flaws or manufacturing challenges early, companies can avoid costly problems later.

This includes preventing expensive tooling modifications, reducing the likelihood of product failures in the field, and ensuring compliance with regulatory standards. It builds confidence in the final product.

Robust prototyping minimizes the overall risk associated with launching a new product.

Optimizing Designs for Scalability

Through iterative prototyping and testing, designs can be refined not just for performance, but also for optimal manufacturability at scale. This involves streamlining part designs and assembly processes.

Our DFM expertise, gained from extensive experience as a source manufacturer, ensures that prototypes are developed with an eye towards efficient mass production. This proactive approach saves time and money.

The final prototype is a blueprint that is ready for a smooth transition to high-volume manufacturing.

Benefits of a Source CNC Manufacturer

Guaranteed Quality and Process Control

As a dedicated source manufacturer, ‘ly-machining’ maintains complete control over every aspect of the `custom CNC prototyping` process, from material selection to final inspection. This guarantees consistent, high-quality output.

We adhere to stringent quality management systems, including standards like ISO 9001, ensuring every part meets precise specifications. Our internal QC processes are rigorous and thorough.

This vertical integration provides unparalleled reliability and quality assurance for your projects.

Direct Communication and Dedicated Support

Working directly with a source manufacturer means streamlined communication channels. You interact directly with our technical experts and project managers, eliminating intermediaries.

This direct line of communication ensures that your specific needs and design nuances are fully understood and accurately implemented. Our team provides dedicated support and expert advice throughout the project.

We believe in fostering a true partnership built on clear communication and mutual understanding.

Unbeatable Value and Service Efficiency

Our direct manufacturing model allows us to offer `prototype machining services` at highly competitive prices without compromising quality. We optimize efficiency to deliver exceptional value.

By cutting out unnecessary overheads and maintaining a lean operation, we pass those savings directly to our clients. Our focus is on long-term partnerships.

This results in a superior overall experience, combining top-tier quality with cost-effectiveness and speed.

Case Study: Accelerating a Medical Device Launch

A client specializing in advanced medical devices faced significant delays and escalating costs with their previous prototyping supplier. Their complex, multi-component design required extremely tight tolerances and specialized material testing. The slow iteration cycle was pushing back their crucial FDA approval timeline.

Our solution involved implementing our `rapid prototyping CNC` services, focusing on simultaneous manufacturing of multiple design iterations using medical-grade plastics and stainless steel. Our DFM experts worked closely with their engineers to optimize the design for both performance and eventual mass production. We delivered a series of fully functional prototypes within 7 days per iteration.

The result was transformative: the client reduced their prototype cycle time by 40% and, through early defect identification, avoided a costly redesign that would have added months to their project. They secured FDA approval three months ahead of schedule, enabling an earlier market entry and a significant competitive advantage. This partnership underscored the power of speed, precision, and expert collaboration in `custom CNC prototyping`.

Conclusion: The Future of Rapid CNC

Recap of Core Advantages for Innovation

The advantages of `rapid prototyping CNC` are clear: it dramatically accelerates product launch, delivers unmatched precision, ensures cost-effectiveness, grants unparalleled design freedom, and enables robust validation. These benefits collectively revolutionize product development.

For businesses navigating today’s competitive landscape, embracing advanced `CNC rapid prototyping` is essential for sustained innovation and market leadership. It is an investment that pays dividends.

Empowering Your Product Development Journey

By leveraging the capabilities of `prototype machining services`, you empower your engineering and design teams to innovate more boldly and efficiently. This accelerates your time-to-market.

Partnering with an experienced source manufacturer like ‘ly-machining’ ensures that your journey from concept to final product is smooth, precise, and highly successful.

Transform Your Product Development

Request Your Transparent Quote Today

Ready to transform your product development cycle with speed, precision, and cost-efficiency? Contact our expert team today for a transparent, no-obligation quote on your next `custom CNC prototyping` project.

Partner with Our CNC Machining Experts

Let us bring our deep technical expertise and state-of-the-art facilities to your next project. We are here to help you build innovation together.

What is rapid prototyping CNC?

Rapid prototyping CNC is an advanced manufacturing process using computer numerical control machines to quickly produce physical parts directly from digital designs. It’s ideal for creating functional prototypes with high precision and accuracy.

This method allows for rapid design iteration and testing, significantly accelerating product development cycles. It leverages subtractive manufacturing to create parts from various materials.

How does it save costs?

It saves costs by eliminating the need for expensive upfront tooling, such as molds or dies, making it highly efficient for low-volume production. Early detection of design flaws minimizes expensive rework.

The speed of `CNC rapid prototyping` reduces overall project timelines, which translates into lower labor costs and faster market entry. Our transparent pricing also ensures budget predictability.

What materials can be used?

A wide range of engineering-grade materials can be used, including various metals like aluminum, stainless steel, and brass, as well as plastics such as ABS, Nylon, and Polycarbonate. This versatility allows for functional testing.

Specialized engineering resins like PEEK and Delrin are also commonly machined. This broad material compatibility ensures prototypes closely match the properties of the final production part.