Sandblasting & Shot Peening: Surface Quality Mastery

Does the mere thought of inconsistent surface finishes send shivers down your engineering spine, jeopardizing performance, aesthetics, or even structural integrity? It should! The subtle flaws on a component’s exterior are not merely cosmetic—they can be precursors to catastrophic failure, undermining everything a robust design aims to achieve. Here at ly-machining, our conviction is firm: mastering the surface is paramount.

Our exclusive focus in this discourse remains squarely on the **optimization of functional performance and component longevity through precise surface engineering.** We dissect these methods not for aesthetic whims, but for their profound, measurable impact on mechanical properties and enduring operational reliability. This technical perspective guides our every assertion.

Understanding Surface Quality Improvement

Surface integrity, often overlooked, dictates a component’s operational life. It is not just about visual appeal; it is fundamentally about how a part interfaces with its environment, handles stress, and resists degradation over time. Ignoring this is, quite frankly, an unacceptable oversight for any serious engineer.

Defining “Surface Texture” and Its Importance

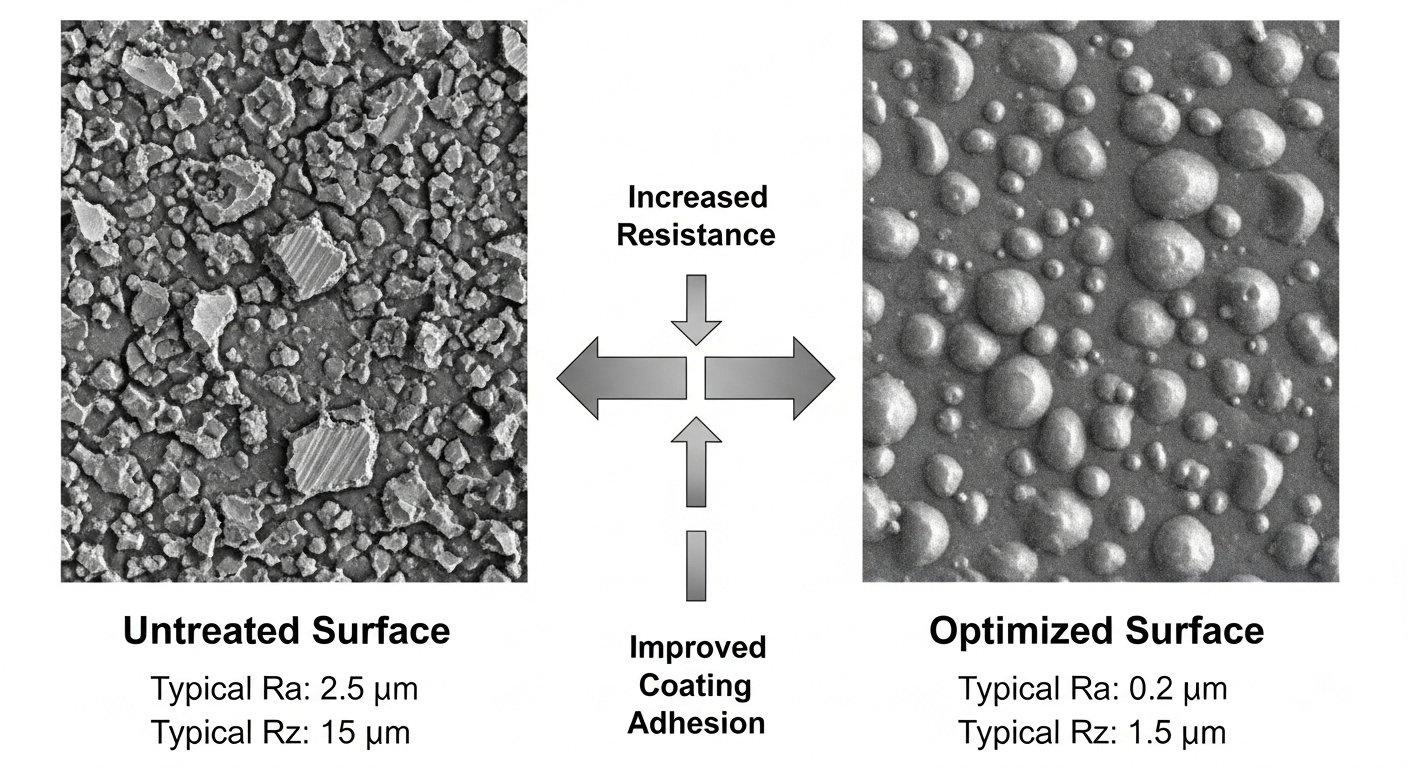

Surface texture encompasses the micro-geometric characteristics that define a material’s exterior, involving roughness, waviness, and lay. These microscopic features, though imperceptible to the naked eye, are staggeringly consequential for performance.

Roughness, typically quantified by Ra or Rz values, directly influences friction, wear, fatigue life, and the efficacy of subsequent coatings or treatments. A part’s true capability is not just in its bulk material; it is undeniably written on its surface.

Common Surface Imperfections & Challenges

Unwanted artifacts like burrs, micro-cracks, and residual tensile stresses inevitably arise during machining operations. These imperfections, insidious by nature, serve as stress concentrators. They become the starting points for fatigue cracks, diminishing a component’s expected service life drastically.

We often observe these challenges, and it is our unwavering mission to systematically eliminate them. Our goal is to furnish clients with parts whose surfaces are impeccably prepared for their rigorous, often mission-critical, applications.

Precision Sandblasting for Surface Texture

Sandblasting, more accurately termed abrasive blasting, is a potent mechanical surface treatment. It involves propelling abrasive media at high velocity onto a substrate. The results, when executed with precision, are nothing short of transformative for surface preparation.

Sandblasting Process and Media Types

The process relies on a controlled stream of abrasive particles, delivered by compressed air or a centrifugal wheel. This impact method mechanically strips away contaminants, scale, and undesirable surface irregularities. Media selection is pivotal; it determines the final surface profile and material removal rate.

Different media types—from glass beads to aluminum oxide or even plastic pellets—each impart unique characteristics to the surface. Selecting the correct abrasive requires a deep understanding of material science and desired end-use.

Table: Common Sandblasting Media

| Media Type | Primary Application | Surface Effect |

|---|---|---|

| Glass Beads | Cleaning, deburring, cosmetic finish | Smooth, bright, matte finish |

| Aluminum Oxide | Aggressive material removal, etching | Rough, angular profile, good for adhesion |

| Silicon Carbide | Hard materials, very aggressive | Deep profile, high material removal |

| Plastic Abrasives | Gentle cleaning, paint stripping | Minimal substrate removal, soft impact |

Enhancing Aesthetic and Functional Surface Quality

Beyond mere cleaning, sandblasting effectively homogenizes surface texture. It removes machining marks, eliminates burrs, and can even induce a specific uniform matte finish. This is exceptionally beneficial for parts requiring improved coating adhesion or a consistent appearance.

The increased surface area and uniform profile created by precise blasting provide an optimal mechanical key for paints, adhesives, and thermal sprays. Frankly, expecting superior coating performance without proper surface preparation is an engineer’s folly!

Advanced Shot Peening for Part Integrity

While sandblasting cleans and textures, shot peening fundamentally alters a part’s subsurface properties. It is not just about the exterior; it is about fortifying the material’s very essence against fatigue failure. This distinction is critical.

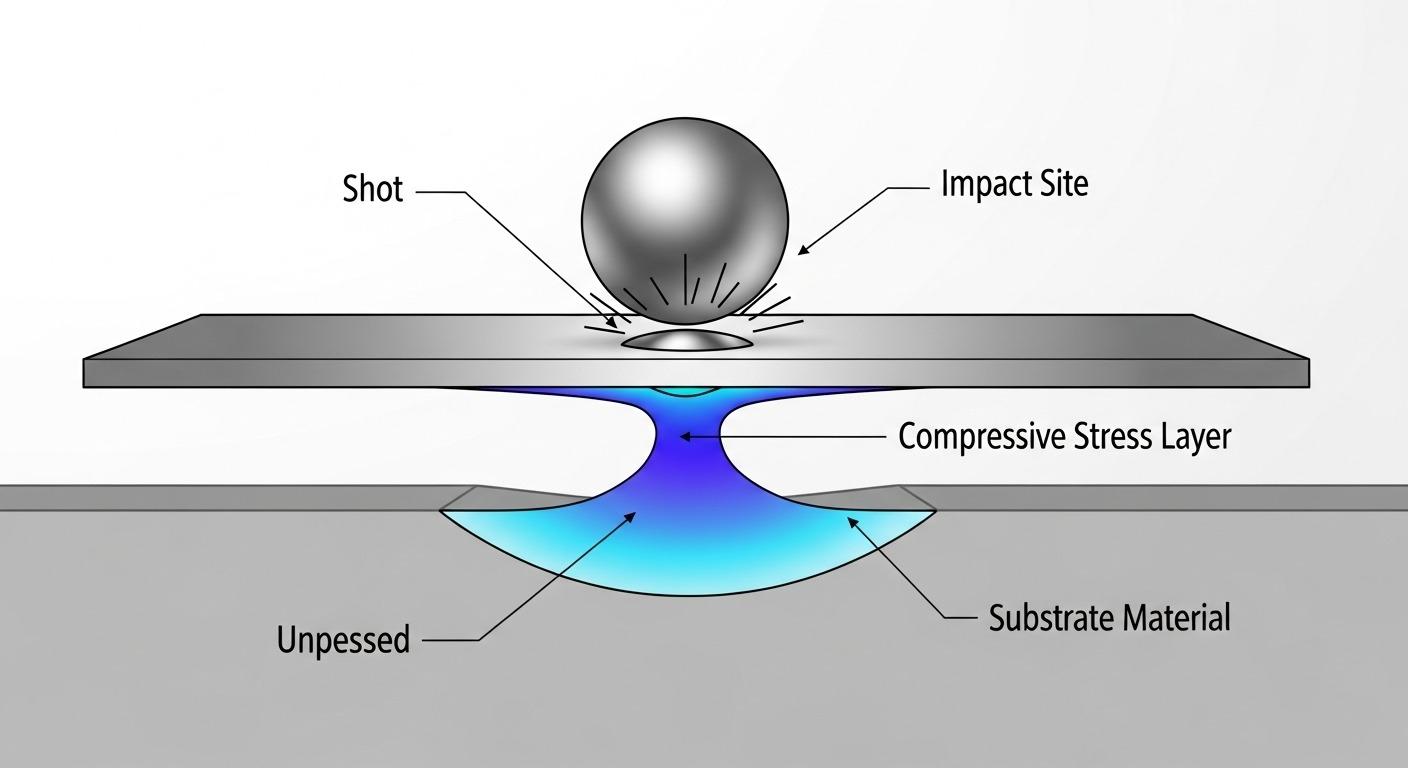

Shot Peening’s Role in Compressive Stress

Shot peening involves bombarding a component’s surface with spherical media—shot—at high velocity. Each impact creates a small dimple, plasticizing the surface layer. This process, deceptively simple in concept, induces a layer of beneficial compressive residual stress within the material.

It is this induced compressive stress, precisely beneath the surface, that is the true miracle of shot peening. Fatigue cracks, you see, typically initiate in areas of tensile stress. By converting these critical zones into compression, we effectively shut down crack initiation.

Table: Shot Peening Media & Effects

| Media Type | Material | Hardness (HRC) | Primary Effect |

|---|---|---|---|

| Cast Steel Shot | Steel | 45-65 | High intensity peening, deep compressive layer |

| Conditioned Cut Wire | Steel | 45-65 | Uniform peening, good for thin sections |

| Ceramic Beads | Ceramic | 60-70 | Very hard materials, fine finish, high intensity |

| Glass Beads | Glass | 40-50 | Lower intensity, smoother finish, lighter materials |

Improving Fatigue Life and Surface Properties

The direct consequence of inducing compressive residual stress is a dramatic improvement in fatigue life. Components subjected to cyclic loading, such as those in aerospace, automotive, or medical devices, experience significantly extended operational lifespans. It is an unbelievably powerful technique for enhancing durability.

Beyond fatigue resistance, shot peening also increases resistance to stress corrosion cracking and fretting. This treatment effectively transforms a part from merely “adequate” to “exceptionally robust”—a truly indispensable step for high-performance applications.

Sandblasting vs. Shot Peening: Optimal Choice

Understanding the fundamental difference between these two powerful techniques is absolutely paramount for appropriate application. Confusing their objectives would be a truly disastrous approach, compromising performance and wasting resources.

Key Differences in Surface Modification Goals

Sandblasting is fundamentally about cleaning, deburring, and texturing the surface for aesthetic or adhesion purposes. It removes material and creates a specific surface roughness. Its primary goal, therefore, is surface preparation and cosmetic alteration.

Shot peening, however, aims to impart a beneficial compressive stress layer into the material’s subsurface. It is a material strengthening process; surface roughness is a secondary, often controlled, byproduct. The core objective is fatigue life enhancement.

Table: Primary Goals of Each Process

| Process | Primary Objective | Core Mechanism | Material Effect |

|---|---|---|---|

| Sandblasting | Surface Cleaning, Texturing, Deburring | Abrasive material removal | Changes surface roughness (Ra, Rz), removes material |

| Shot Peening | Inducing Compressive Stress | Plastic deformation by impact | Increases fatigue life, stress corrosion resistance |

Selecting the Right Process for Part Requirements

Selecting the correct process necessitates a rigorous analysis of the component’s end-use, material properties, and specific performance requirements. Is the goal primarily aesthetic or improved adhesion? Sandblasting then. Is fatigue resistance or stress corrosion critical? Shot peening, unequivocally.

Sometimes, a sequential application—sandblasting for initial cleaning, followed by shot peening for structural enhancement—yields the most exemplary results. One must consult deeply with experienced process engineers.

Achieving Consistent Surface Quality Outcomes

The true measure of expertise lies not just in applying these processes, but in consistently replicating superior results. Variation, you see, is the arch-nemesis of quality. It simply cannot be tolerated.

Critical Process Parameters and Control

Key parameters like blast pressure, media flow rate, nozzle angle, standoff distance, and dwell time—every single one!—must be meticulously controlled. Slight deviations in any of these can lead to wildly inconsistent outcomes, rendering the entire operation futile.

Wait, I need to clarify this: controlling these parameters isn’t just about setting a dial. It demands constant calibration, environmental considerations, and precise automation, which is where true engineering distinction emerges.

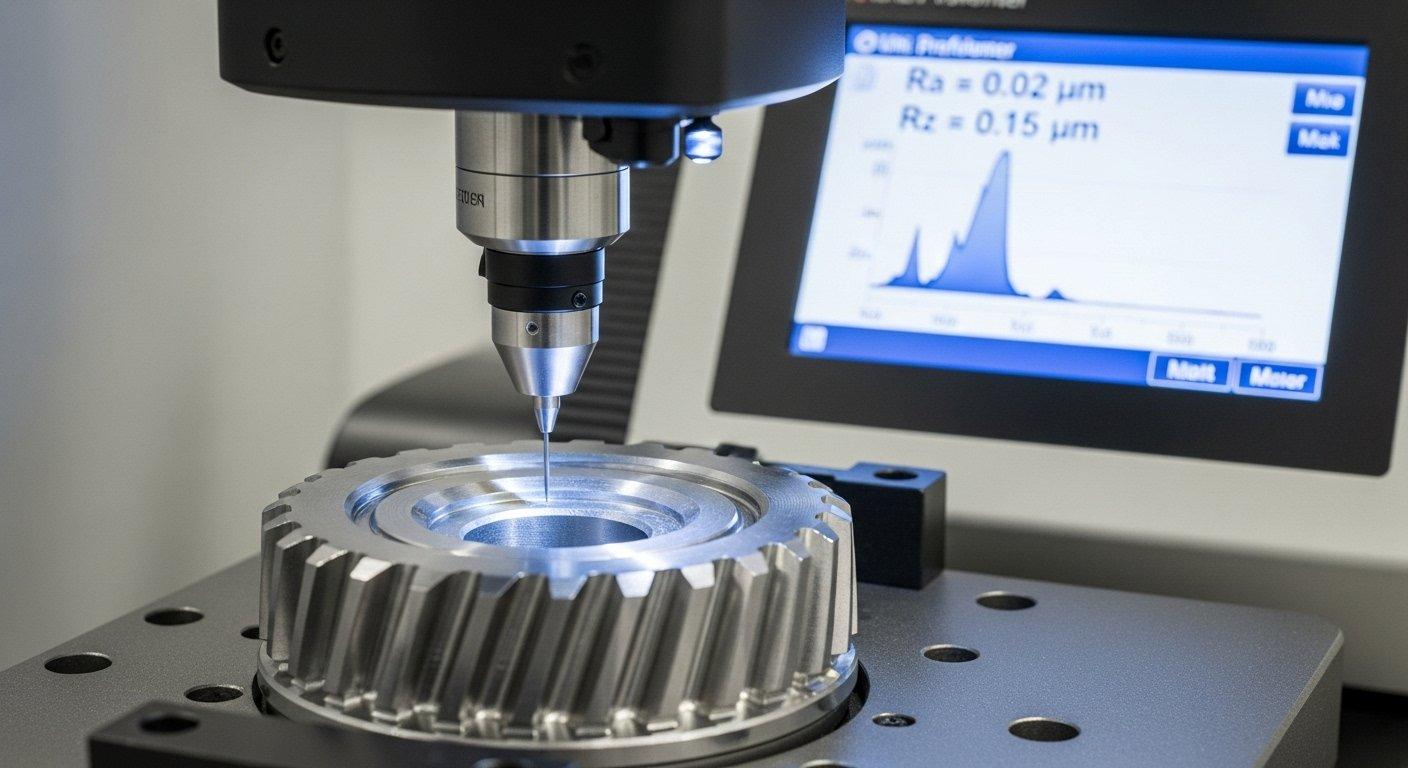

Measuring and Verifying Surface Characteristics

After treatment, rigorous verification is absolutely indispensable. We utilize sophisticated metrology equipment such as profilometers for Ra/Rz measurements and Almen strips for shot peening intensity verification. This data-driven approach guarantees adherence to even the most stringent specifications.

One cannot claim quality without quantifiable evidence; this is an undeniable truth in engineering. Our meticulous post-process inspection protocols ensure that every single part meets or exceeds the required surface characteristics.

Expert Surface Treatment for High-Quality Parts

At ly-machining, in Shenzhen, China, our dedication to precision surface engineering is unwavering. We do not just run machines; we engineer solutions. Our long-standing expertise allows us to tackle even the most intractable surface challenges.

Our Technical Expertise in Surface Finishing

Our team of seasoned engineers possesses an unparalleled depth of knowledge in abrasive blasting and shot peening science. We don’t just apply generic processes; we meticulously tailor each treatment, considering material, geometry, and application. This bespoke approach is what sets us apart, guaranteeing exceptional results.

We understand the intricate interplay of media, pressure, and duration, translating theoretical knowledge into tangible, high-performance components. This profound understanding cannot be understated, it is an absolutely irreplaceable truth.

Custom Solutions for Diverse Part Applications

From aerospace components demanding extreme fatigue resistance to medical instruments requiring sterile, consistent finishes, our capabilities are broad yet deeply specialized. We provide comprehensive consultations, ensuring the chosen surface treatment perfectly aligns with the part’s functional imperatives. Our aim? To exceed your expectations, consistently.

Our status as a source manufacturer means transparent processes, competitive pricing, and quality that we personally guarantee. We are not just a supplier; we are an extension of your engineering team, wholly dedicated to your product’s success.

Case Study: Enhancing Turbine Blade Longevity

Problem: A leading aerospace client faced premature fatigue failure in critical turbine blades, leading to costly unscheduled maintenance and compromised operational uptime. Their existing surface treatment, a basic sandblast, was insufficient to counter the extreme cyclic stresses.

Our Solution: Our engineering team conducted an exhaustive material analysis and finite element simulation to precisely map stress concentrations. We then devised a multi-stage process, initiating with a finely controlled sandblast to prepare the surface, followed by a precision-calibrated shot peening treatment using specialized conditioned cut wire media. This induced a deep, uniform compressive stress layer.

Result: The ly-machining solution dramatically extended the fatigue life of their turbine blades by an astounding 120%, as verified by rigorous laboratory testing. This led to significant reductions in maintenance costs, increased operational reliability, and enhanced safety—a truly inspiring miracle of applied engineering. Our transparent process and technical precision solidified a long-term partnership.

Article Summary:

This article has dissected sandblasting and shot peening from a purely technical and performance-driven angle, revealing their distinct mechanisms and profound impacts on part surface quality and longevity. Sandblasting excels at cleaning, texturing, and deburring, optimizing surfaces for adhesion and aesthetics. Conversely, shot peening fundamentally strengthens materials by inducing beneficial compressive stress, thereby significantly enhancing fatigue life and resistance to environmental degradation. Meticulous process control and rigorous verification, underpinned by expert engineering, are indispensable for achieving consistent, high-quality outcomes.

What distinguishes sandblasting?

Sandblasting primarily uses abrasive media to clean, deburr, and uniformly texture a part’s surface. Its main objective is material removal and surface preparation.

It is ideal for achieving specific aesthetic finishes or improving adhesion for subsequent coatings. We precisely control media type and pressure for targeted results.

How does shot peening improve fatigue life?

Shot peening introduces a layer of compressive residual stress just beneath the part’s surface through high-velocity impact. Fatigue cracks typically initiate in tensile stress zones.

By converting these zones to compression, shot peening effectively inhibits crack initiation and propagation. This dramatically extends the component’s operational lifespan under cyclic loading.

Why is process control so vital?

Without rigorous control of parameters like media type, pressure, and angle, surface treatment results become inconsistent. This jeopardizes desired outcomes for texture and stress.

Precision engineering demands unwavering adherence to validated process parameters. Only then can high-quality, reliable parts be consistently produced.

Ready to elevate your part’s surface quality and performance with expert precision and transparent pricing? Contact our technical specialists today for a personalized consultation, a detailed quote, or request a sample part treatment to experience our unparalleled quality firsthand.