Finding a top Shenzhen CNC machining factory means prioritizing a true source manufacturer with robust quality control, transparent pricing, and deep technical expertise for precision CNC parts.

Navigating the bustling industrial landscape of Shenzhen to find a reliable CNC machining partner can be a complex endeavor. The sheer volume of options often makes distinguishing a genuine, high-caliber factory from a mere trading company incredibly challenging for procurement managers and design engineers alike. The stakes are high, with quality, lead time, and cost directly impacting your project’s success and market competitiveness.

This guide, from an experienced manufacturer’s perspective, aims to illuminate the critical factors and provide a clear roadmap for identifying truly superior CNC machining partners in Shenzhen. We will delve into what sets the best apart, focusing on the transparency, technical prowess, and unwavering commitment to quality that defines a top-tier supplier for precision CNC parts.

Navigating Shenzhen CNC Manufacturer Choices

Why Shenzhen for Precision Machining?

Shenzhen stands as a global epicenter for manufacturing, especially for electronics and high-tech components. Its dense ecosystem supports an unparalleled concentration of skilled labor, advanced infrastructure, and a robust supply chain for materials and ancillary services.

In our experience, this concentration creates a competitive environment that fosters innovation and efficiency, allowing for rapid prototyping and economical scaling to mass production volumes. The technical capabilities found here are often at the forefront of the industry.

Table: Shenzhen’s Advantages in CNC Machining

| Advantage | Description |

|---|---|

| Supply Chain | Extensive network for materials, tools, and finishes |

| Skilled Workforce | High density of experienced CNC engineers and operators |

| Infrastructure | Modern logistics, power, and communication networks |

| Technology Adoption | Early adoption of advanced machining technologies |

Your True Cost of CNC Machining Partners

The unit price for precision CNC parts is only one component of the total cost of ownership. Factors like rework rates, delays due to poor communication, and the need for additional inspections all contribute significantly to the overall project expense.

A seemingly low upfront cost can quickly escalate if the supplier lacks robust quality control or technical support. In our view, true value comes from a partner who minimizes these hidden costs through reliability and expertise.

Finding a Reliable CNC Source Manufacturer

Distinguishing a genuine Shenzhen machining factory from a trading company is paramount. Trading companies act as intermediaries, often adding layers of communication and increasing the risk of misinterpretation or quality control issues.

A true source manufacturer, like us, directly owns and operates the machines, employs the engineers, and manages the entire production process. This direct control ensures accountability, consistent quality, and efficient problem-solving for your precision CNC parts.

Key Qualities of a Top Shenzhen CNC Factory

Uncompromising Precision & Technical Skills

Top-tier CNC manufacturers are defined by their ability to achieve and consistently hold tight tolerances across diverse materials and complex geometries. This requires not only state-of-the-art machinery but also experienced machinists and advanced programming expertise.

In our work, we find that the mastery of challenging materials and the ability to produce exceptional surface finishes are hallmarks of a factory with true technical depth. These skills are crucial for critical applications such as aerospace or medical devices.

Table: Typical Achievable Tolerances (Metals)

| Material | General Tolerance (mm) | Fine Tolerance (mm) |

|---|---|---|

| Aluminum | ±0.05 | ±0.02 |

| Stainless Steel | ±0.06 | ±0.025 |

| Titanium | ±0.07 | ±0.03 |

| Brass | ±0.04 | ±0.015 |

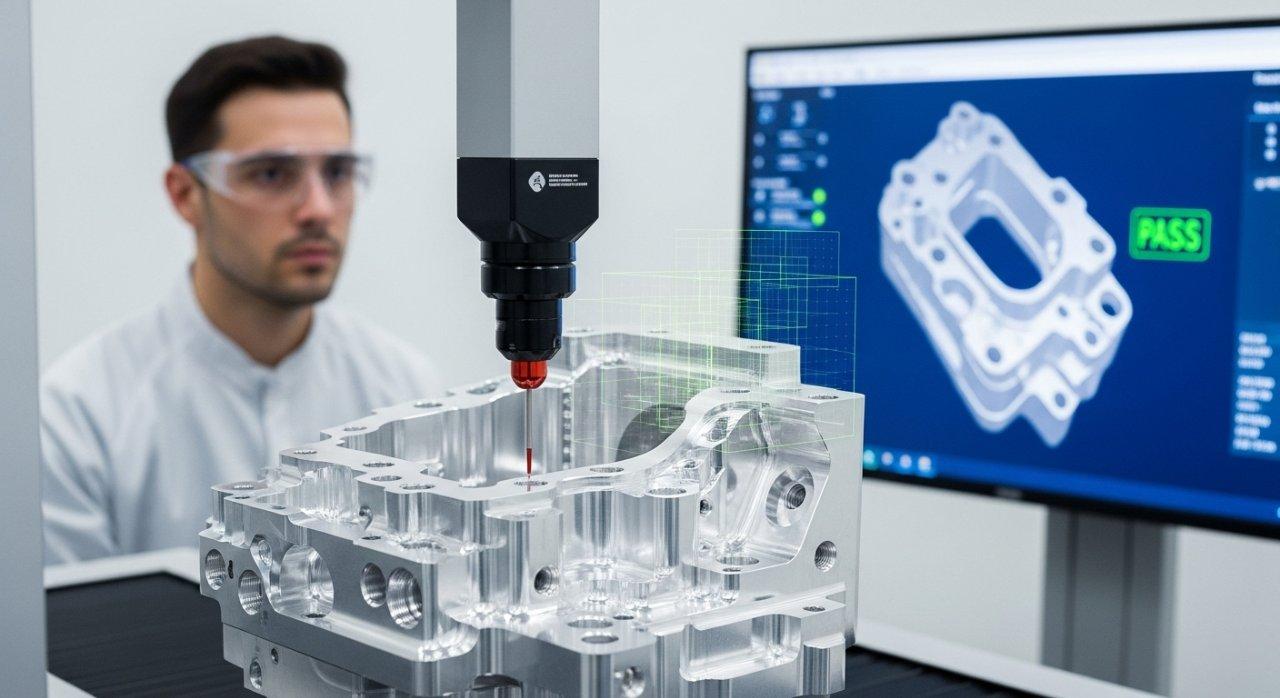

Robust Quality Control for Machined Parts

A superior Shenzhen CNC machining factory implements rigorous, multi-stage quality control. This extends from incoming material inspection, through in-process checks, to final dimensional verification using advanced equipment like CMMs.

Certifications such as ISO 9001 and AS9100 are not merely badges; they represent a systemic commitment to quality assurance and continuous improvement. We believe these standards are non-negotiable for producing reliable precision CNC parts.

Transparent Pricing and No Hidden Fees

Trustworthy partners offer clear, itemized quotes that detail material costs, machining time, surface finishes, and any secondary operations. Hidden fees for tooling or unforeseen surcharges are a common pain point we encounter from clients seeking better partners.

Our approach prioritizes transparency, ensuring clients understand the full scope of costs upfront. This fosters a relationship built on trust and predictability, crucial for long-term collaborations.

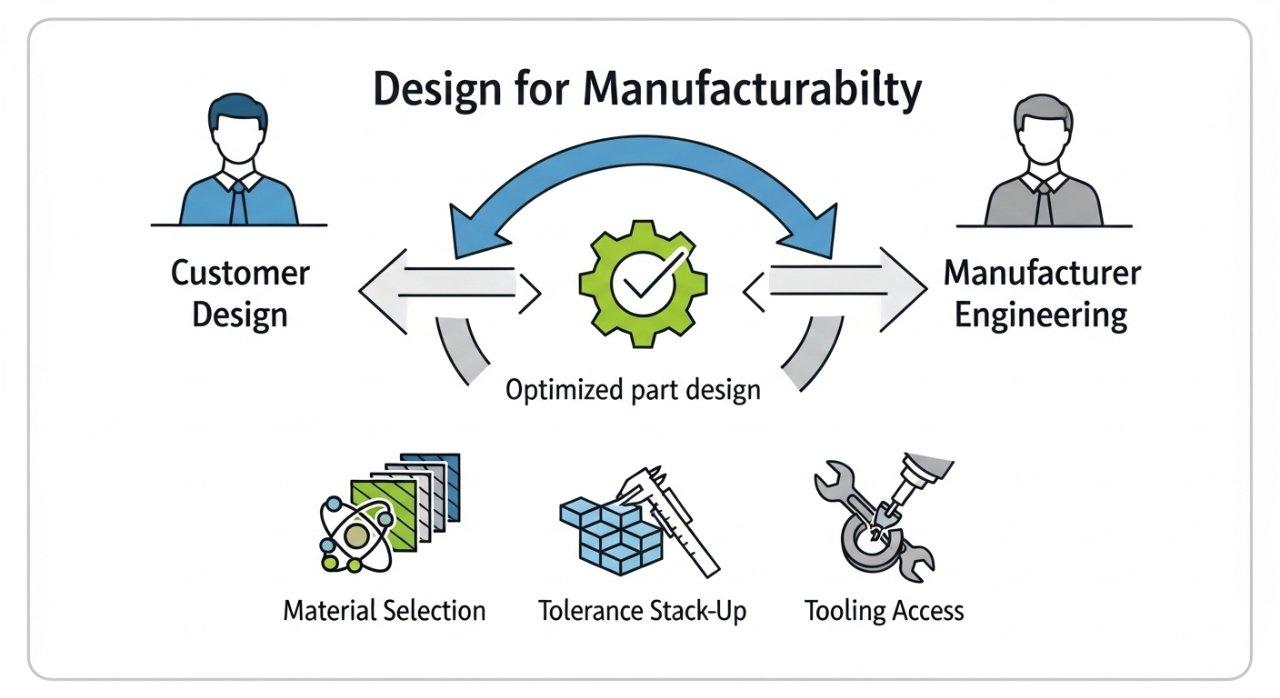

Deep Technical Expertise and DFM Support

A truly top Shenzhen machining factory provides more than just manufacturing services. They offer proactive Design for Manufacturability (DFM) support, identifying potential issues in design phase to optimize cost, lead time, and quality.

This level of engineering consultation, based on years of hands-on experience, ensures that your designs are not just produced but perfected. It’s an invaluable service that prevents costly errors and accelerates product development.

Our Edge in Shenzhen CNC Machining

As a Source Manufacturer: Our Commitment

At ly-machining, we are a dedicated source manufacturer, meaning we control every aspect of the production process. From material sourcing to final inspection and packaging, all operations are performed in our state-of-the-art Shenzhen machining factory.

This integrated approach guarantees full accountability, consistent quality control, and direct communication channels. We eliminate intermediaries, ensuring a streamlined process for delivering your precision CNC parts.

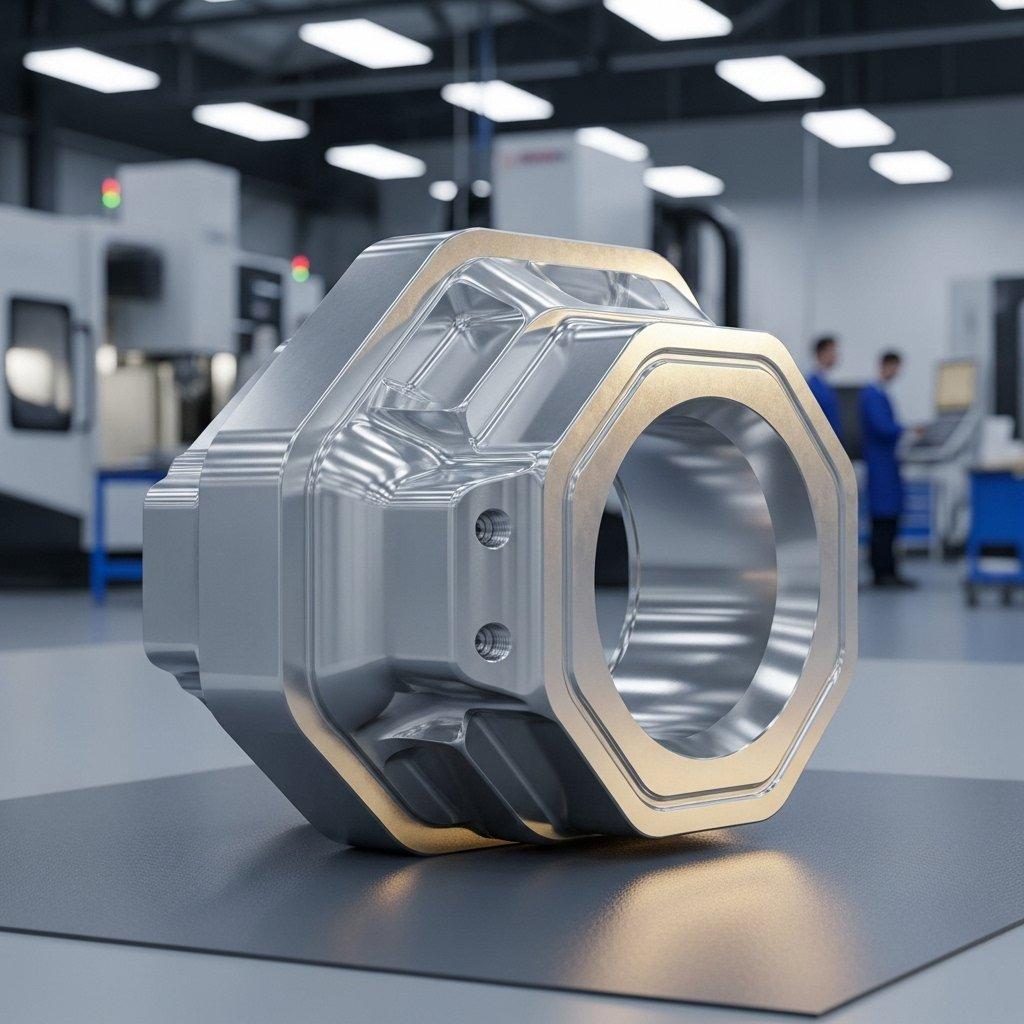

Delivering Unmatched High-Quality Parts

Our commitment to high-quality parts is evident in our meticulous material selection, advanced machining techniques, and stringent quality checks. We work with a wide range of engineering-grade materials, from aerospace aluminum alloys to medical-grade titanium.

We specialize in complex geometries and tight tolerances, consistently achieving surface finishes that exceed industry standards. This dedication ensures your components perform exactly as designed, every time.

Transparent Pricing for Clear Value

We believe in straightforward and honest pricing. Our quotes provide a detailed breakdown, explaining the cost drivers and offering potential optimizations through DFM suggestions. There are no hidden fees or unexpected charges when partnering with us.

Our aim is to build long-term relationships based on mutual trust and clear financial understanding. This transparency helps you manage your project budgets effectively, without surprises.

Our Advanced Machining Capabilities

Our Shenzhen machining factory is equipped with a comprehensive suite of modern CNC machinery, including multi-axis milling and turning centers. This allows us to handle highly complex geometries and precise machining operations with exceptional efficiency.

We continuously invest in the latest technology and our team’s training to stay at the forefront of precision manufacturing. This ensures we can meet the evolving demands for advanced precision CNC parts across various industries.

Table: ly-machining’s Core Capabilities

| Capability | Key Features | Typical Applications |

|---|---|---|

| 3, 4, 5-Axis Milling | Complex contours, deep pockets, tight tolerances | Aerospace, Medical, Robotics |

| CNC Turning | High precision for cylindrical parts, intricate details | Connectors, Shafts, Bushings |

| Material Expertise | Aluminum, Stainless Steel, Titanium, Brass, Plastics | Diverse industries, custom components |

| Surface Finishing | Anodizing, Polishing, Grinding, Bead Blasting | Aesthetics, Functionality, Durability |

How to Evaluate Shenzhen CNC Factories

Assessing CNC Machine & Facility Standards

When evaluating potential Shenzhen CNC machining factories, look beyond simple capacity. The age and maintenance of their machinery directly impact precision and reliability. Modern, well-maintained equipment is essential for consistent quality.

A clean, organized factory environment also reflects a disciplined approach to manufacturing and quality control. This visual indicator often correlates with higher operational standards and better output for precision CNC parts.

Verifying Supplier Quality Certifications

Beyond verbal assurances, request proof of certifications like ISO 9001, AS9100 (for aerospace), or ISO 13485 (for medical devices). These independently audited standards demonstrate a systematic commitment to quality.

Material certifications (MTRs) for raw stock are also crucial, particularly for demanding applications. These documents provide verifiable proof of material composition and properties, ensuring part integrity.

Understanding Project Communication Flow

Effective communication is a cornerstone of successful projects, especially across international borders. Inquire about the factory’s communication protocols, response times, and the availability of English-speaking project managers.

A clear escalation path for technical or logistical issues is also vital. In our experience, proactive and transparent communication prevents misunderstandings and keeps projects on schedule.

Success Stories: Real CNC Project Examples

Reviewing a factory’s past project examples provides tangible evidence of their capabilities and expertise. Look for projects similar in complexity, material, and required precision to your own.

A top Shenzhen CNC machining factory should be able to share relevant success stories or showcase a portfolio of precision CNC parts that demonstrate their ability to meet diverse industry standards.

Partner with a Shenzhen Machining Expert

Request a Quote for Precision CNC Parts

Choosing the right Shenzhen CNC machining partner is a critical decision that impacts your product’s quality, cost, and time to market. At ly-machining, we stand ready to demonstrate our expertise.

We invite you to experience the difference a dedicated, high-precision source manufacturer can make for your next project requiring precision CNC parts.

Consult Our Engineering Team Today

Our team of experienced engineers is available to discuss your specific project requirements, offer DFM insights, and provide a transparent quotation. We are committed to being a reliable extension of your R&D and procurement teams.

Case Study: Accelerating Medical Device Prototyping

Problem: A U.S.-based medical device startup needed rapid prototyping of a complex titanium surgical implant. The parts required extremely tight tolerances (±0.01mm) and a specific biocompatible surface finish, with a tight deadline for clinical trials. Their previous supplier struggled with consistency and lead times.

Our Solution: Our engineering team engaged in immediate DFM analysis, optimizing the CAD models for our 5-axis CNC machines and suggesting a specialized post-machining passivation process to achieve the required surface finish. We allocated dedicated machining capacity.

Result: We delivered the first batch of precision titanium implants within 10 days, meeting all stringent quality and dimensional specifications. The client successfully advanced to clinical trials on schedule, praising our technical communication and manufacturing reliability, and subsequently engaged us for mass production.

Get a free quote or technical consultation today to see how ly-machining can elevate your next precision project.

What defines a top Shenzhen CNC machining factory?

A top Shenzhen CNC machining factory is characterized by its direct manufacturing capabilities, demonstrated expertise in precision and complex parts, and a robust quality control system, often backed by ISO or AS9100 certifications. They also offer transparent pricing and strong technical support.

Their commitment to continuous improvement and investment in advanced machinery is paramount. Such factories prioritize reliable delivery and clear communication.

How does a source manufacturer impact cost and quality?

A source manufacturer directly controls the entire production process, from raw material inspection to final quality checks. This eliminates intermediary markups and communication layers, often resulting in more competitive pricing and higher quality consistency.

With a source manufacturer, there is direct accountability for every part produced. This direct oversight minimizes risks of errors and delays.

What critical documentation should I request from a Shenzhen machining factory?

You should always request quality certifications (e.g., ISO 9001, AS9100, ISO 13485 where applicable), material test reports (MTRs) for raw materials, and a detailed First Article Inspection (FAI) report for initial parts.

Additionally, a comprehensive DFM report and transparent, itemized quotations are crucial. These documents collectively verify their capabilities and commitment to quality.