A robust CNC quality control system is paramount for delivering precision CNC parts, ensuring custom CNC machining meets exacting specifications and providing unwavering machining quality assurance from start to finish.

In custom CNC machining, is ‘good enough’ truly good enough, or are hidden quality issues costing your project valuable time and money? We understand the critical importance of impeccable quality in every component. Our uncompromising quality control system transforms uncertainty into predictable precision, delivering peace of mind.

As a leading source manufacturer, ‘ly-machining’ leverages deep technical expertise and transparent processes to guarantee superior results. This guide will detail how our rigorous quality assurance framework ensures every precision CNC part we produce meets the highest standards. Discover how our proven approach safeguards your investment and empowers your innovation.

Why CNC Quality Control is Critical

The hidden costs of poor quality

Poor quality in custom CNC machining can lead to significant, often underestimated, costs beyond initial rework. In our experience, these include costly assembly line interruptions, increased scrap rates, and severe warranty claims. Such issues erode profit margins and delay product launches significantly.

These hidden expenses far outweigh any perceived savings from inadequate quality control systems. Investing in rigorous machining quality assurance upfront prevents these downstream financial drains. It ensures every precision CNC part meets requirements from the first run.

Protecting your project timeline

Non-conforming parts are a major cause of project delays, directly impacting critical production schedules. Late delivery of key components can halt entire manufacturing processes. This creates a ripple effect of missed deadlines and increased pressure.

A meticulously managed CNC quality control system acts as a shield against such disruptions. It guarantees components are delivered on time and to specification, maintaining project momentum. This reliability is vital for fast-paced industries relying on custom CNC machining.

Reputation and client trust

Consistently high-quality precision CNC parts are the cornerstone of any strong client relationship. Delivering unreliable or inconsistent components quickly damages a manufacturer’s reputation. Trust, once lost, is incredibly difficult to regain.

Our commitment to a stringent CNC quality control system builds lasting confidence with our partners. We aim to be a dependable extension of your team, providing machining quality assurance you can consistently rely on for your custom CNC machining needs.

Meeting strict industry standards

Many industries, such as aerospace, medical, and automotive, operate under extremely strict regulatory and quality standards. Adherence to these, like ISO 9001 and AS9100, is not optional but mandatory. Our quality control system is built upon these foundations.

We ensure every custom CNC machining project complies with the necessary certifications and client-specific requirements. This rigorous approach demonstrates our authoritativeness and commitment to delivering the highest level of machining quality assurance.

Pillars of Our CNC Quality System

Source manufacturer advantage

As a direct source manufacturer, we maintain complete control over the entire custom CNC machining process. This means absolute oversight from raw material procurement to final inspection and delivery. There are no hidden third-party variables.

This integrated approach allows us to implement our comprehensive CNC quality control system directly at every stage. It fosters unmatched consistency and precision in every precision CNC part we produce.

Deep technical expertise in QC

Our quality control team comprises highly certified engineers and experienced technicians with specialized knowledge in precision metrology. They undergo continuous training in the latest quality assurance methodologies. This ensures we stay at the forefront of the industry.

This deep expertise is fundamental to our machining quality assurance, allowing us to interpret complex GD&T requirements and anticipate potential quality challenges. Our proactive approach is a hallmark of our custom CNC machining services.

Transparent processes guarantee

Transparency is integral to our CNC quality control system. We believe in open communication regarding our processes, inspection reports, and corrective actions. Clients are welcome to audit our facilities and documentation.

This openness builds trustworthiness and ensures our partners fully understand the measures we take to guarantee machining quality assurance. It provides a clear, verifiable chain of quality for every custom CNC machining project.

Preventing defects, not just detecting

Our philosophy is centered on defect prevention, not merely detection after the fact. We integrate Design for Manufacturability (DFM) principles and Failure Mode and Effects Analysis (FMEA) at the design review stage. This identifies and mitigates risks proactively.

By implementing robust process controls and leveraging data analysis, we establish stable and predictable manufacturing operations. This proactive stance significantly reduces the likelihood of non-conformances in our precision CNC parts.

Stages of Our Custom CNC QC System

Design and engineering review

Every custom CNC machining project begins with a thorough design and engineering review. Our team scrutinizes client specifications, CAD models, and blueprints, analyzing GD&T requirements. We identify potential manufacturing challenges.

This collaborative review ensures all design intent is fully understood and technically feasible. It forms the bedrock of the entire CNC quality control system, preventing issues before production even begins.

Material inspection and traceability

Incoming raw materials are subjected to stringent inspection upon arrival. We verify material certifications (MTRs) against order specifications. Physical properties are often checked through destructive or non-destructive testing.

Each batch of material is assigned a unique identifier for complete traceability throughout the manufacturing process. This ensures that the provenance and quality of every precision CNC part can be verified.

| Material Property | Inspection Method | Standard Reference |

|---|---|---|

| Chemical Composition | XRF, Spectrometry | ASTM E1476 |

| Mechanical Properties | Tensile, Hardness | ASTM E8, ASTM E18 |

| Dimensional | Calipers, Micrometers | ISO 286 |

| Surface Integrity | Visual Inspection | Internal SOP |

In-process checks and monitoring

During custom CNC machining, continuous in-process checks are performed by our skilled operators and dedicated QC staff. This includes first-off article inspection (FAI) before batch production commences. Operators utilize precision measuring tools at regular intervals.

Statistical Process Control (SPC) is employed to monitor critical dimensions and process parameters. This real-time data allows for immediate adjustments, ensuring consistent machining quality assurance throughout the production run.

Post-machining inspection and FAI

After the machining process is complete, every precision CNC part undergoes a comprehensive final inspection. This includes 100% dimensional verification for critical features using advanced CMMs. First Article Inspection reports (FAI) are generated for new parts.

These detailed reports provide comprehensive documentation of dimensional compliance, crucial for machining quality assurance. Where applicable, we also prepare Production Part Approval Process (PPAP) documentation for automotive and related industries.

Surface finish and cosmetic checks

Surface finish is a critical parameter, particularly for functional and aesthetic precision CNC parts. We utilize profilometers and advanced vision systems to objectively measure surface roughness (Ra, Rz values). Visual inspections are conducted for any cosmetic defects.

This includes checking for burrs, scratches, pits, and tool marks that fall outside specified limits. Our rigorous approach ensures the surface integrity of every custom CNC machining component meets or exceeds client expectations.

| Surface Finish Parameter | Description | Common Methods | Standard Unit |

|---|---|---|---|

| Ra (Roughness Average) | Arithmetic mean deviation | Stylus Profilometry | µm (micro-meter) |

| Rz (Mean Peak-to-Valley) | Average of ten highest peaks and ten deepest valleys | Stylus Profilometry | µm (micro-meter) |

| Visual Inspection | Absence of cosmetic defects | Human Eye, Magnifier | N/A |

Packaging and shipping integrity

The final step in our CNC quality control system ensures that precision CNC parts arrive at your facility in perfect condition. We employ appropriate packaging methods tailored to the part’s fragility and material. This protects against damage during transit.

Proper labeling, part identification, and protective wrapping are meticulously applied. This attention to detail guarantees that the integrity of our custom CNC machining quality is maintained right through to your receiving dock.

Key Technologies in CNC Quality Control

CMM and precision measurement

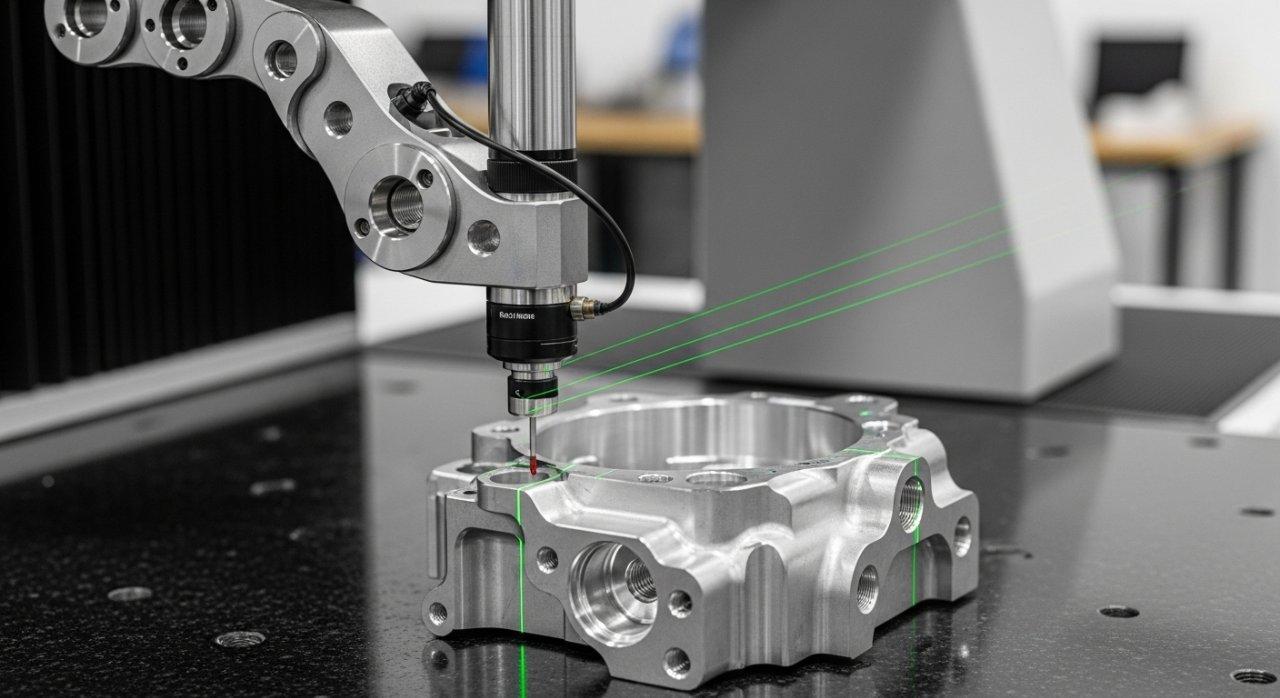

Our inspection labs are equipped with state-of-the-art Coordinate Measuring Machines (CMMs). These advanced systems allow for highly accurate, three-dimensional measurement of complex geometries and tight tolerances. Our multi-axis CMMs can measure features down to sub-micron levels.

This technology is indispensable for verifying the dimensional accuracy of precision CNC parts against CAD models. It provides comprehensive and repeatable measurement data, foundational to our machining quality assurance.

Statistical process control (SPC)

Statistical Process Control (SPC) is a proactive methodology we integrate into our CNC quality control system. By collecting and analyzing real-time data from production processes, we can identify trends and potential deviations. This allows for timely intervention.

SPC charts help us maintain consistent process stability and capability. This data-driven approach is critical for predicting and preventing quality issues, ensuring continuous improvement in our custom CNC machining operations.

Advanced non-contact inspection

For delicate parts, intricate features, or high-volume inspection, we utilize advanced non-contact inspection technologies. These include optical comparators, vision systems, and laser scanners. They provide rapid, highly accurate measurements without touching the part.

These tools are particularly effective for surface profile analysis, edge detection, and measuring small, complex geometries. They complement our traditional contact measurement methods, enhancing our overall machining quality assurance capabilities.

Calibration and equipment upkeep

The accuracy of our measurement equipment is fundamental to our CNC quality control system. All inspection tools, from calipers to CMMs, undergo rigorous, regularly scheduled calibration. This adheres to international standards.

Detailed maintenance logs and calibration certificates ensure full traceability and compliance. This commitment to equipment upkeep guarantees the integrity of every measurement taken on our precision CNC parts.

Ensuring Custom CNC Part Precision

Custom tolerance management

We understand that different custom CNC machining projects demand varying levels of precision. Our engineers work closely with clients to define and manage custom tolerance requirements. We offer expertise in achieving exceptionally tight tolerances.

Our process considers material properties, machining capabilities, and application-specific needs. This collaborative approach ensures that every precision CNC part meets your exact specifications efficiently and reliably.

| Tolerance Grade | Description | Application Examples | Achievability |

|---|---|---|---|

| Coarse (IT16-18) | Loose tolerances | Non-critical components, rough fits | Easily Achieved |

| Medium (IT10-14) | General machining | Standard mechanical parts | Standard |

| Fine (IT6-9) | Precision fits | Bearings, gear shafts | Requires Control |

| Very Fine (IT01-5) | High precision, aerospace | Medical implants, optics | Advanced QC Required |

Complex geometry verification

Verifying complex geometries, especially for multi-axis machined parts, presents unique challenges. Our advanced metrology equipment and expert team are adept at navigating these complexities. We utilize CAD-to-part comparison software.

This ensures that intricate contours, complex curves, and precise angles are accurately measured and verified. This capability is vital for delivering the advanced precision CNC parts demanded by cutting-edge industries.

Collaborative quality planning

We believe that successful machining quality assurance is a collaborative effort. From project inception, we engage with our clients in quality planning. This involves defining critical-to-quality (CTQ) features and inspection points.

This partnership ensures alignment on quality expectations and methodology. It’s a proactive step in our CNC quality control system, minimizing surprises and maximizing satisfaction for every custom CNC machining order.

Continuous improvement cycles

Our commitment to excellence drives a culture of continuous improvement, central to our CNC quality control system. We regularly review our processes, analyze performance data, and implement corrective and preventative actions (CAPA). This is based on feedback and internal audits.

Utilizing methodologies like PDCA (Plan-Do-Check-Act), we constantly refine our custom CNC machining processes. This ensures our machining quality assurance evolves, consistently delivering better precision CNC parts.

Partnering for Reliable CNC Parts

Transparent pricing, clear value

Our transparent pricing model clearly reflects the value added by our robust CNC quality control system. We provide detailed quotes that itemize costs, ensuring you understand where your investment goes. The reliability and precision we guarantee ultimately reduce your overall project costs.

By mitigating risks of rework and delays, our machining quality assurance translates into predictable project outcomes. This clarity ensures you receive superior precision CNC parts without hidden expenses.

Certifications and compliance

‘ly-machining’ proudly holds industry-recognized certifications, including ISO 9001, demonstrating our commitment to quality management. We also comply with specific industry standards such as AS9100 for aerospace applications. This underlines our capabilities for highly demanding custom CNC machining.

These certifications provide independent verification of our rigorous CNC quality control system. They give our clients confidence in our processes and our ability to consistently deliver compliant, high-quality precision CNC parts.

Our commitment to excellence

Our unwavering commitment to excellence is embodied in every precision CNC part we produce. From initial design review to final delivery, our entire team is dedicated to upholding the highest standards of machining quality assurance. This drives our custom CNC machining processes.

We view every project as an opportunity to demonstrate our expertise and reliability. Partnering with ‘ly-machining’ means choosing a manufacturer dedicated to your success, powered by an industry-leading CNC quality control system.

Unlock Flawless Custom CNC Parts

Case Study: Ensuring Critical Accuracy for a Robotics Innovator

**Problem:** A robotics client approached ‘ly-machining’ after experiencing repeated failures with a previous supplier. Their crucial robotic arm components, requiring extremely tight positional tolerances and specific surface finishes, consistently arrived out of spec, leading to assembly issues and significant project delays. The previous supplier’s quality control system was insufficient.

**Our Solution:** Our team immediately engaged in a thorough Design for Manufacturability (DFM) review, identifying subtle design features that contributed to manufacturing difficulties. We implemented a rigorous First Article Inspection (FAI) plan for the initial batch, utilizing our 5-axis CMM to verify all critical dimensions down to micron levels. During production, real-time Statistical Process Control (SPC) monitored key machining parameters. This ensured consistency throughout the custom CNC machining process.

**Result:** ‘ly-machining’ successfully delivered 500 precision CNC parts within the agreed timeframe, all verified to be within the specified tolerances and surface finish requirements. The client reported zero assembly issues and significantly improved robot performance. This robust machining quality assurance allowed their project to resume on schedule, cementing ‘ly-machining’ as their trusted, long-term partner for complex precision components.

Ready to elevate your custom CNC projects with guaranteed precision and unparalleled reliability? Contact our expert team today for a no-obligation consultation and discover how our robust quality control system can safeguard your investment.

What is CNC quality control?

CNC quality control is a systematic process. It ensures that custom CNC machined parts consistently meet all specified design requirements and tolerances. This involves checks at every stage, from material selection to final inspection.

It uses advanced tools and methodologies like CMMs, SPC, and FAI. The goal is to prevent defects, ensure dimensional accuracy, and deliver reliable precision CNC parts.

How do you ensure tight tolerances?

We ensure tight tolerances through a multi-faceted approach. This includes meticulous design review, precise machine calibration, and rigorous in-process monitoring using SPC. Our operators are highly skilled.

Advanced metrology equipment, such as 5-axis CMMs, performs post-machining verification. This combines with a culture of continuous improvement.

What certifications do you hold?

‘ly-machining’ holds critical industry certifications. This includes ISO 9001 for quality management systems. These demonstrate our commitment to global quality standards.

We also comply with specific sector requirements, such as AS9100 for aerospace projects. These certifications underscore our dedication to top-tier machining quality assurance.