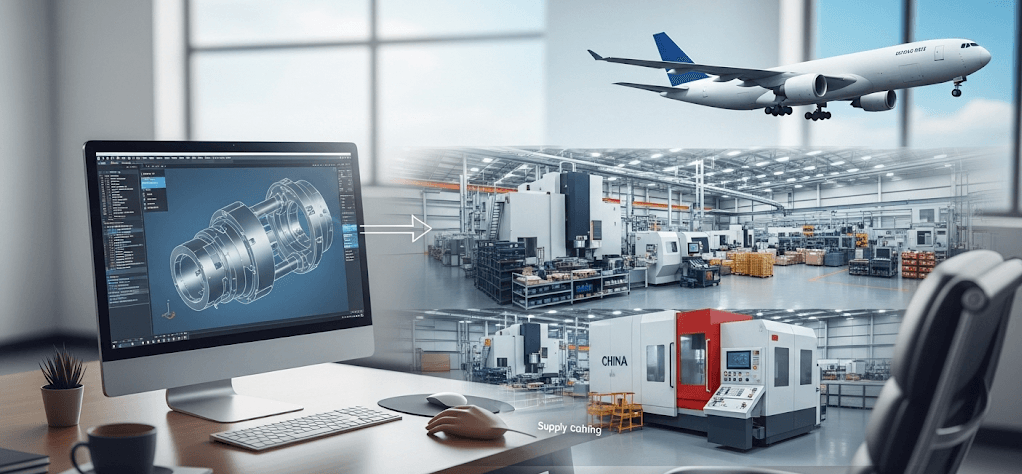

Sourcing custom CNC parts from China offers immense potential for cost savings and access to vast manufacturing capacity. However, navigating the landscape of suppliers can be overwhelming, leaving you uncertain about which manufacturer can truly meet your quality and reliability standards. How do you identify a top-tier partner from thousands of options?

This uncertainty can lead to significant risks: receiving low-quality CNC parts, experiencing costly production delays, or facing communication barriers that derail your project. Without a clear strategy, your attempt to optimize costs could result in compromised components that jeopardize your final product. You need a reliable framework for vetting and selecting a world-class CNC machining partner.

This guide provides a clear roadmap for sourcing from China’s leading CNC machining manufacturers. By focusing on key evaluation criteria—from technical capability to quality control and communication—you can confidently select a partner like [ly-machining], who embodies the quality and reliability of a premier supplier. We will help you identify a manufacturer that delivers exceptional CNC parts on time, every time.

Why Source Custom CNC Parts from China?

For decades, China has been a global hub for manufacturing, and its capabilities in high-precision CNC machining have grown impressively. Companies worldwide choose Chinese manufacturers for several compelling reasons:

- Cost-Effectiveness: Lower labor and operational costs allow Chinese suppliers to offer competitive pricing, especially for larger production runs of custom CNC parts. This enables significant budget savings without compromising on advanced manufacturing technology.

- Scalability and Capacity: Chinese CNC machining facilities often operate on a large scale with extensive numbers of machines. This provides massive capacity, allowing them to handle everything from rapid prototypes to high-volume production runs with shorter lead times than many domestic suppliers.

- Integrated Supply Chains: The manufacturing ecosystem in China is deeply integrated. A single CNC milling provider can often manage the entire production process, including sourcing raw materials, machining, finishing, and even assembly, streamlining the entire procurement process.

However, realizing these benefits depends entirely on choosing the right partner. A top manufacturer distinguishes itself through more than just price.

The Anatomy of a Premier Chinese CNC Machining Manufacturer

Identifying a leading supplier requires looking beyond surface-level promises. A truly capable CNC machining partner demonstrates excellence across several key areas. They provide not just parts, but a professional service experience. The following sections outline the critical criteria you should use to evaluate potential manufacturers.

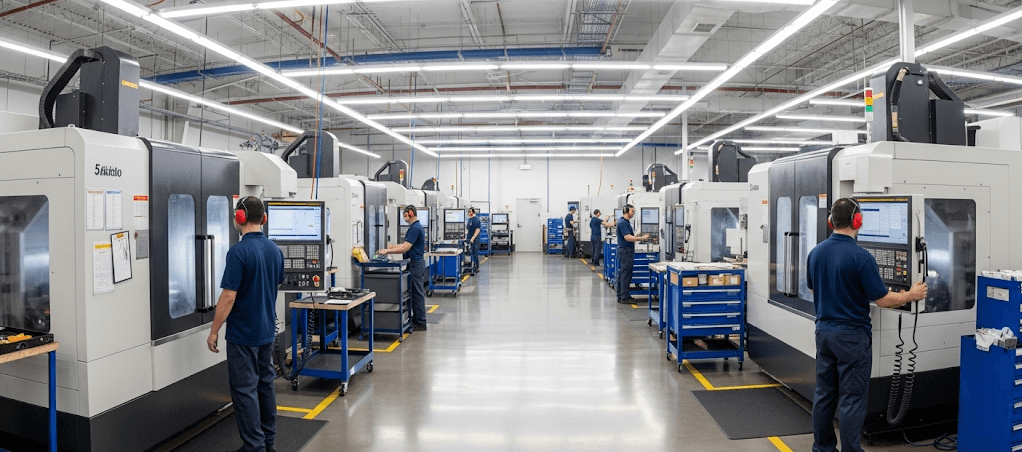

1. Advanced Technical Capabilities

A top-tier manufacturer invests in modern technology. Their capabilities directly impact the quality and complexity of the CNC parts they can produce.

- Machinery: Look for a supplier with a diverse range of well-maintained CNC machines. This should include 3-axis, 4-axis, and crucially, 5-axis CNC milling centers. 5-axis machines can produce highly complex geometries in a single setup, improving accuracy and reducing cost. They should also have high-precision CNC lathes for turning operations.

- Material Expertise: A proficient supplier has proven experience working with a wide array of materials, from standard aluminum and stainless steel to engineering plastics like PEEK and challenging metals like titanium and Inconel. Ask for case studies or examples of past projects involving your desired materials.

- Stated Tolerances: Review the manufacturer’s stated standard tolerances. A high-quality shop should be able to hold tight tolerances, often within ±0.02mm (0.0008″) or better, demonstrating their precision capabilities for custom CNC projects.

At [ly-machining], our investment in advanced 5-axis technology and our deep experience with a broad material portfolio are cornerstones of our service.

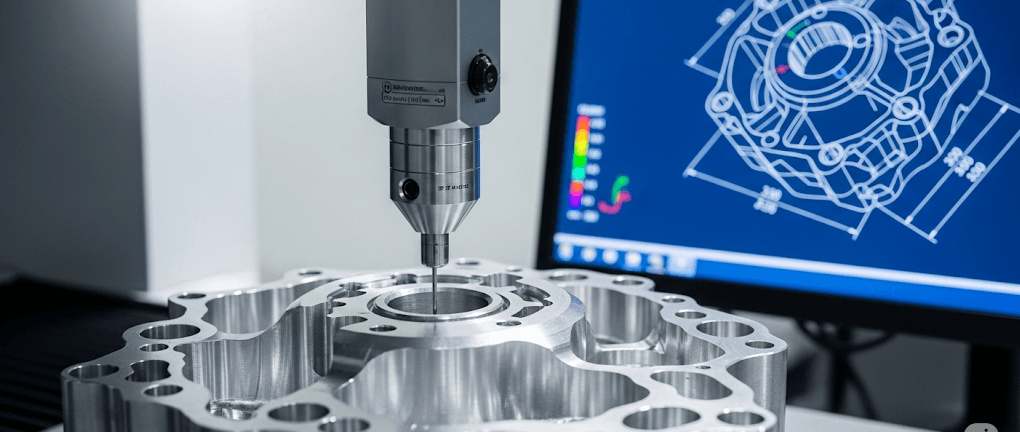

2. Robust Quality Management Systems

Consistent quality is non-negotiable. A premier manufacturer proves their commitment to quality through certified processes and rigorous inspection.

- ISO 9001 Certification: This is a fundamental requirement. ISO 9001 is the international standard for a Quality Management System (QMS). It demonstrates that the supplier has established and follows strict procedures for every aspect of their operation, from quoting to delivery.

- In-Process and Final Inspection: Ask about their quality control procedures. Top suppliers perform in-process inspections (checking parts during the CNC machining process) as well as a thorough final inspection.

- Advanced Inspection Tools: A serious commitment to quality is evident in their inspection lab. Look for advanced metrology equipment like Coordinate Measuring Machines (CMM), profilometers, and material spectrometers. A CMM is essential for verifying complex geometries and tight tolerances on CNC parts.

Our ISO 9001-certified QMS and state-of-the-art CMM inspection ensure that every part we ship meets the most stringent quality standards.

3. Clear and Proactive Communication

When sourcing internationally, clear communication is the key to a successful partnership. A top Chinese supplier will have a dedicated team of English-speaking project managers and engineers.

- Responsiveness: A professional supplier responds to inquiries (like RFQs) promptly, typically within 24 hours. Their communication should be clear, professional, and address all your questions thoroughly.

- Design for Manufacturability (DFM) Feedback: A proactive partner doesn’t just blindly manufacture a design. They provide valuable DFM feedback, suggesting minor changes to your custom CNC design that could reduce costs, improve manufacturability, or enhance the part’s function. This demonstrates their expertise and commitment to your project’s success.

- Regular Updates: For larger projects, a good manufacturer will provide regular updates on the production status without you having to ask, ensuring you are always informed.

4. Proven Project Management and Experience

Look for a manufacturer with a proven track record. Their experience and project management skills ensure your project is delivered smoothly and on time.

- Case Studies and Portfolio: Ask to see their portfolio or case studies of similar projects. This provides tangible proof of their capabilities in CNC milling and machining for industries relevant to yours (e.g., aerospace, medical, automotive).

- Client Testimonials: Reputable suppliers are proud of their work and should be able to provide references or share testimonials from satisfied international clients.

- Experience with International Logistics: A seasoned exporter understands the complexities of international shipping, customs clearance, and documentation. This expertise ensures your CNC parts arrive without unexpected delays or fees.

This sourcing guide can be summarized in a simple checklist for evaluating potential CNC machining partners:

| Evaluation Criterion | What to Look For |

| Technical Capability | 3, 4, and 5-axis CNC machines; Experience with your specific material. |

| Quality System | ISO 9001 certification; CMM and other advanced inspection tools. |

| Communication | Fluent English-speaking team; Provides DFM feedback. |

| Experience | Relevant case studies; Testimonials; International shipping expertise. |

| Lead Time & Price | Competitive pricing; Realistic and reliable lead times. |

Related Questions

How do I handle Intellectual Property (IP) protection with Chinese suppliers?

This is a valid concern. A reputable manufacturer will readily sign a Non-Disclosure Agreement (NDA) before you share sensitive design files. Top-tier suppliers like [ly-machining] understand the importance of IP protection and have strict internal protocols to safeguard your designs. Working with an established company with a strong reputation is your best defense.

What are the typical payment terms for custom CNC orders?

Payment terms can vary, but a common structure for new clients is an upfront deposit (typically 30-50%) before production begins, with the remaining balance due upon completion and before shipment. Established, long-term relationships may allow for more flexible terms. Always ensure the terms are clearly stated in your quote and purchase order.

Frequently Asked Questions

1. Is there a language barrier when working with a top CNC machining manufacturer in China?

With a premier supplier, the language barrier is minimal to non-existent. They invest in a highly proficient team of English-speaking sales engineers and project managers who can discuss complex technical details and ensure nothing is lost in translation. This is a key differentiator of a top-tier partner.

2. How are shipping and customs handled for CNC parts from China?

Experienced Chinese manufacturers have dedicated logistics departments. They can handle all aspects of shipping, including packaging, documentation, and customs declarations. They typically offer various shipping options, such as air freight for speed and sea freight for cost-savings on larger orders, and can provide a door-to-door service (DDP – Delivered Duty Paid).

3. What makes [ly-machining] a top choice for custom CNC machining?

[ly-machining] exemplifies the qualities of a premier Chinese manufacturer. We combine advanced 5-axis CNC technology and a robust, ISO 9001-certified quality system with proactive, English-speaking project management. Our focus on providing DFM feedback and our extensive experience with international clients make us a reliable partner for producing high-quality custom CNC parts.