Mastering Aluminum CNC: Top 10 Cost Control Strategies

Are rising aluminum CNC machining costs silently eroding your profit margins and jeopardizing project timelines? Inconsistent quality and opaque pricing can add layers of complexity to your manufacturing challenges. Discover the industry’s top 10 proven strategies to dramatically cut expenses and boost efficiency without ever compromising on part quality.

Aluminum CNC machining cost control is crucial for project success. By implementing strategic design adjustments, advanced tooling, and optimized processes, manufacturers can significantly reduce expenses. These methods ensure superior quality parts while enhancing efficiency from initial design to final delivery.

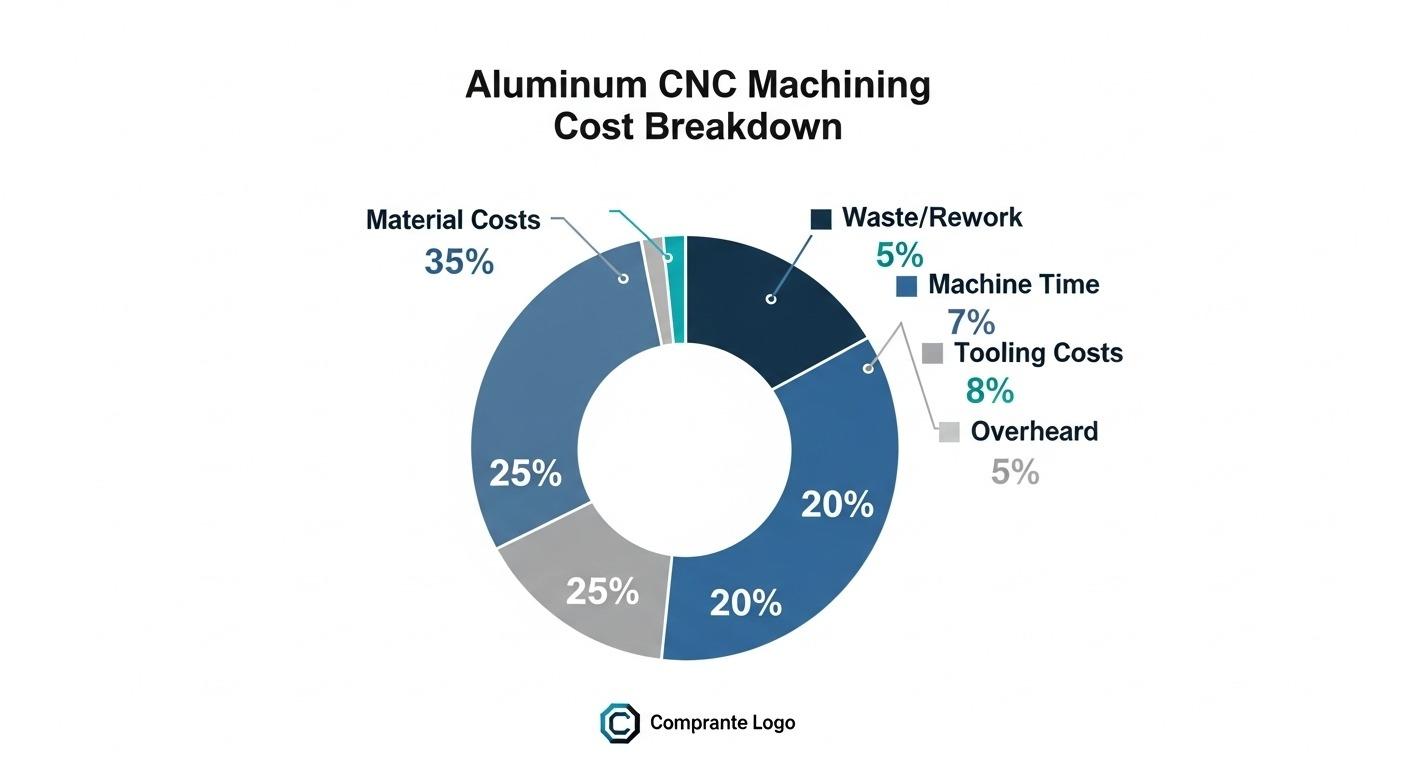

Unveiling Hidden Costs in Aluminum Machining

Understanding the true cost of aluminum CNC machining extends beyond immediate production expenses. Identifying and addressing hidden costs is fundamental to achieving significant savings. These often overlooked factors can silently inflate overall project budgets.

Indirect expenses and overhead impact

Indirect costs, such as energy consumption, machine depreciation, and facility overheads, contribute significantly to the total cost per part. Efficient factory layout and machine utilization directly impact these expenses. Optimizing workflows reduces non-value-added activities.

Material waste and procurement insights

Material waste is a major cost driver. Incorrect blank sizing, aggressive machining parameters, and design flaws lead to excessive scrap. Smart procurement practices, including bulk purchasing and negotiating with trusted suppliers, can secure better material rates and reduce lead times.

Inefficient tooling and wear factors

Suboptimal tooling choices or improper tool maintenance result in increased tool wear, frequent replacements, and costly downtime. Tooling is an investment, and its lifecycle management is key to cost control. Factors like tool coating and geometry are critical.

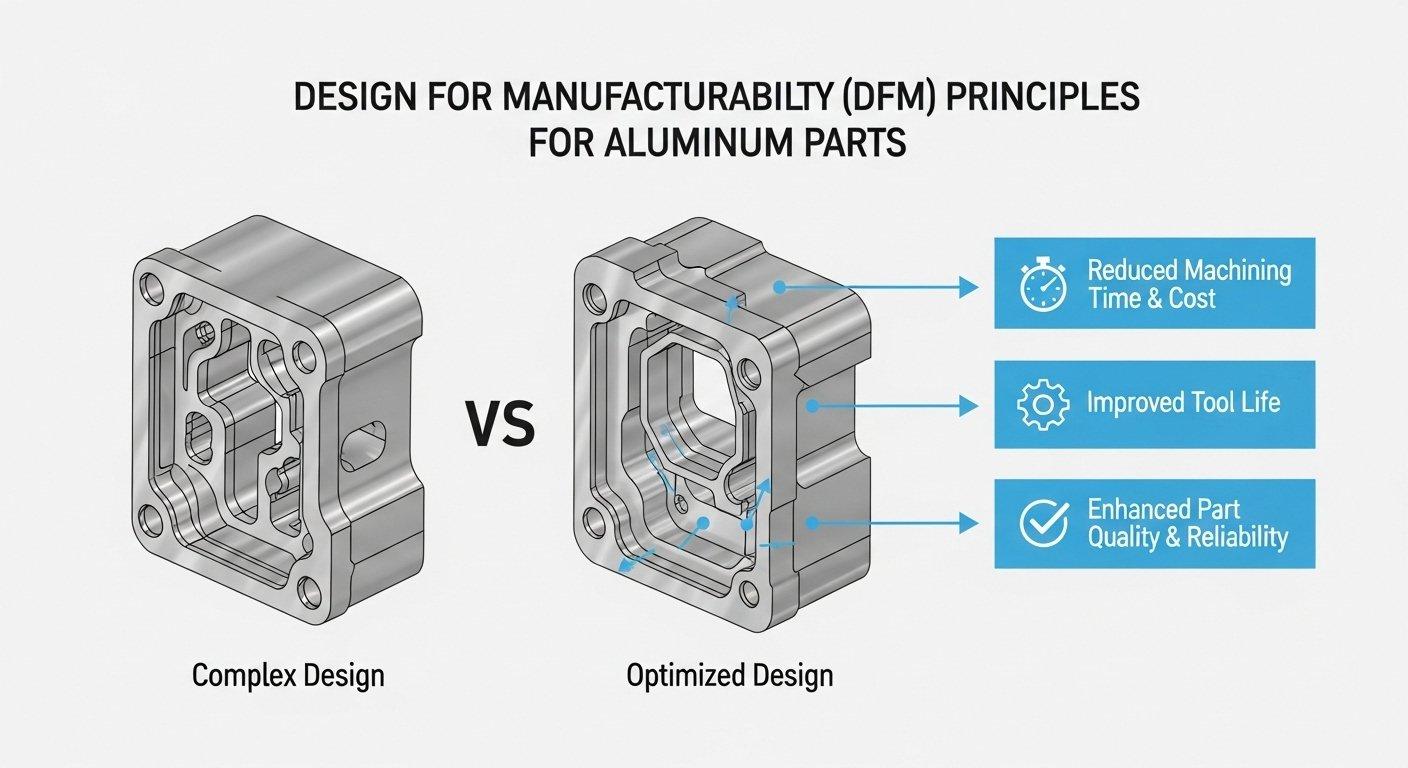

Design for Manufacturability: Aluminum Cost Savings

Design for Manufacturability (DFM) is a proactive approach that optimizes part designs for efficient and cost-effective production. For aluminum components, DFM focuses on material properties, machining capabilities, and minimizing complexity. Engaging DFM early in the design cycle yields the most substantial savings.

Simplifying part geometry for efficiency

Complex geometries often require specialized tooling, multiple setups, and longer machining times. Simplifying radii, avoiding overly thin walls, and designing accessible features can significantly reduce manufacturing effort. Each design decision impacts cycle time directly.

Optimizing tolerances for functionality

Tighter tolerances demand more precise machining, slower feed rates, and rigorous inspection, all of which increase costs. Specifying only necessary tolerances for critical features allows for more economical production elsewhere. Functionality should always drive tolerance specification.

Surface finish selection for cost control

Different surface finishes require varying machining passes and post-processing steps. A mirror-like finish is more expensive to achieve than a standard machined finish. Selecting the appropriate surface finish based on functional or aesthetic requirements, rather than over-specifying, can lead to considerable savings.

Here’s how DFM principles directly impact cost elements:

| DFM Principle | Cost Impact | Efficiency Gain |

|---|---|---|

| Simplify Geometry | Reduces machine time, fewer setups | Faster production, less programming |

| Optimize Tolerances | Avoids rework, lower inspection costs | Increased yield, quicker throughput |

| Sensible Surface Finish | Minimizes post-processing, less tool wear | Reduced cycle time, longer tool life |

Strategic Material Selection for Aluminum CNC

The choice of aluminum alloy profoundly influences both performance and machining costs. Different grades offer varied mechanical properties, machinability, and price points. A thorough understanding of these factors is essential for optimal material selection.

Grade analysis for performance vs. cost

Common aluminum alloys like 6061 and 7075 offer distinct characteristics. 6061 is highly versatile and cost-effective, while 7075 provides superior strength at a higher price. Matching the alloy to the specific application requirements ensures both performance and budget efficiency.

| Aluminum Alloy | Key Characteristics | Typical Applications | Cost Consideration |

|---|---|---|---|

| 6061-T6 | Good strength, excellent machinability | General purpose, structural components | Economical |

| 7075-T6 | High strength, good fatigue resistance | Aerospace, high-stress parts | Moderate to High |

| 2024-T3 | High strength, good fatigue resistance | Aircraft structures, fasteners | Moderate |

| 5052-H32 | Good corrosion resistance, weldability | Marine, electronics enclosures | Economical |

Raw material sourcing and stock forms

Sourcing raw materials from reliable suppliers ensures consistent quality and competitive pricing. Additionally, the form of the raw material (e.g., bar stock, plate, extrusion) can impact initial cost and subsequent machining time. Choosing the most suitable stock form minimizes material removal.

Minimizing waste through smart blank sizing

Precision blank sizing, where the raw material closely matches the near-net shape of the final part, significantly reduces material waste and machining time. This approach requires careful planning and coordination with material suppliers. It also lowers chip disposal costs.

Advanced Tooling Strategies for Aluminum Efficiency

Effective tooling is a cornerstone of efficient aluminum CNC machining. Investing in high-quality, application-specific tools and optimizing their use can dramatically reduce cycle times, improve surface finish, and extend tool life. This leads to substantial cost savings.

Precision cutting tool selection techniques

Selecting the right cutting tool involves considering material, geometry, coatings, and flute count. For aluminum, sharp, polished flutes are often preferred to prevent chip adhesion. High-performance carbide tools, designed specifically for aluminum, can operate at higher speeds and feeds.

Optimized tool path and programming

Advanced CAM software enables the generation of highly optimized tool paths that minimize air cutting, reduce tool engagement, and manage chip evacuation effectively. Strategies like trochoidal milling or high-speed machining (HSM) are particularly beneficial for aluminum. This reduces machining time and tool wear.

Maximizing tool life and performance

Proper coolant application, precise tool holders, and consistent machine maintenance all contribute to maximizing tool life. Regular tool inspection and timely replacement prevent catastrophic tool failures and expensive part rework. Adhering to manufacturer-recommended parameters is crucial.

Factors influencing tool choice for aluminum:

| Tool Parameter | Impact on Aluminum Machining | Cost/Efficiency Benefit |

|---|---|---|

| Flute Count | Fewer flutes (2-3) for better chip evacuation | Faster metal removal, reduced chip recutting |

| Helix Angle | Higher helix (30-45 degrees) for smooth cuts | Improved surface finish, lower cutting forces |

| Coating | AlTiN or TiCN for extended wear resistance | Longer tool life, fewer tool changes |

| Edge Preparation | Sharp, polished edge | Prevents built-up edge, better chip flow |

Process Streamlining: Aluminum Machining Optimization

Optimizing the machining process itself goes beyond individual tool choices. It encompasses the entire workflow, from part loading to final inspection. Streamlining these steps minimizes idle time and maximizes machine utilization, directly impacting efficiency and cost.

Innovative fixturing and workholding

Custom or modular fixturing solutions ensure secure part clamping, minimize deformation, and allow for multiple parts to be machined in a single setup. Quick-change fixturing systems reduce setup times significantly, especially for high-volume production. This approach improves accuracy and repeatability.

Reducing setup and changeover times

Implementing SMED (Single-Minute Exchange of Dies) principles, pre-setting tools offline, and using standardized work instructions drastically cut down setup and changeover times. Reduced downtime translates directly into increased machine availability and higher throughput.

Multi-axis machining for complex parts

For complex aluminum parts, 4-axis or 5-axis machining reduces the need for multiple setups, minimizing handling errors and cumulative tolerance stack-up. While initial machine investment is higher, the efficiency gains for intricate parts often lead to lower per-part costs and faster lead times.

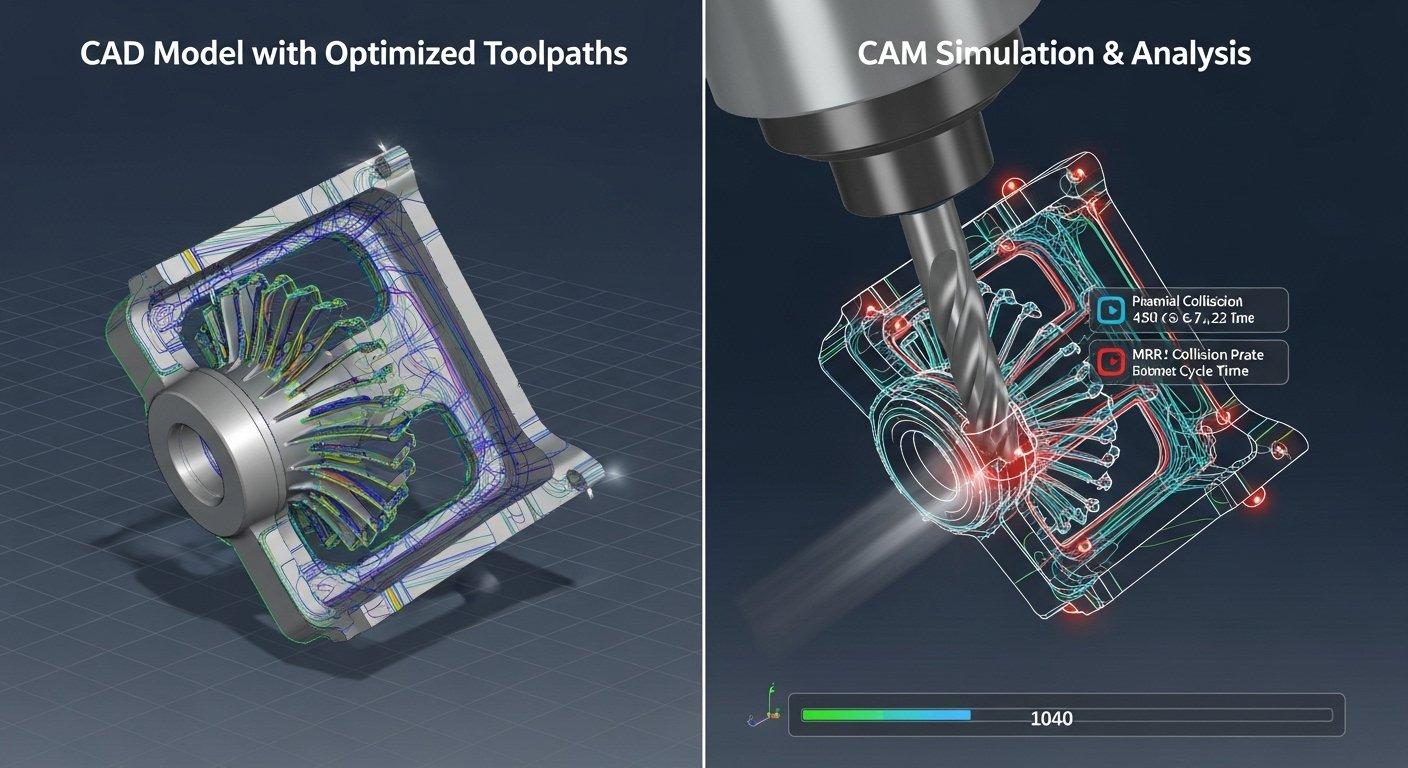

Leveraging CAM Software for Aluminum Cost Reduction

Modern Computer-Aided Manufacturing (CAM) software is indispensable for optimizing aluminum CNC machining processes. Its advanced capabilities allow for precise control over tool paths, simulation, and automation, directly contributing to cost reduction and enhanced efficiency.

Simulation and collision avoidance

CAM software’s simulation features allow engineers to visualize the entire machining process virtually. This identifies potential collisions, errors, and inefficiencies before any material is cut. Eliminating these issues pre-production saves expensive material, machine time, and prevents costly repairs.

Advanced toolpath generation

Sophisticated algorithms within CAM software generate highly efficient tool paths tailored for aluminum. These include high-speed machining (HSM) strategies, trochoidal milling, and dynamic motion, which maintain a constant chip load, reduce tool wear, and maximize material removal rates.

Automation for lights-out production

Integrating CAM with automation solutions, such as robotic loading/unloading or pallet changers, enables lights-out manufacturing. This allows machines to run unattended for extended periods, significantly reducing labor costs and maximizing machine utilization, particularly for high-volume aluminum part production.

Quality Control: Mitigating Rework in Aluminum Parts

Robust quality control (QC) is not merely an inspection step but a proactive strategy to prevent defects, reduce rework, and eliminate scrap. For aluminum parts, consistent quality ensures customer satisfaction and minimizes the financial burden of non-conforming products.

In-process measurement and feedback loops

Implementing in-process measurement systems, such as on-machine probing or laser scanners, allows for real-time dimensional checks. This enables immediate adjustments to machining parameters, preventing a batch of parts from being out of tolerance. Feedback loops improve process stability.

First article inspection best practices

A comprehensive First Article Inspection (FAI) ensures that the initial part produced meets all design specifications before full production commences. This critical step validates the entire manufacturing process, tooling, and programming, preventing widespread quality issues.

Statistical process control (SPC) benefits

Statistical Process Control (SPC) uses statistical methods to monitor and control a process. By tracking key characteristics of aluminum parts over time, SPC identifies process drift before it leads to defects. This proactive approach maintains consistency and reduces variability, leading to higher yields.

Key quality control methods:

| QC Method | Primary Benefit for Aluminum Parts | Cost Reduction Impact |

|---|---|---|

| In-Process Probing | Real-time dimension verification | Prevents entire batch rework, saves material |

| First Article Inspection (FAI) | Validates initial setup and programming | Avoids mass production errors, reduces scrap |

| Statistical Process Control (SPC) | Predicts and prevents defects | Reduces scrap rates, improves yield |

Supply Chain Synergy for Aluminum Cost Control

An optimized supply chain is crucial for controlling costs in aluminum CNC machining. Strategic partnerships and efficient logistics minimize delays, reduce inventory holding costs, and ensure a reliable flow of materials and services.

Vendor consolidation and strong partnerships

Consolidating vendors for raw materials, tooling, and specialized processes creates stronger relationships, often leading to better pricing, preferential lead times, and improved communication. A trusted network of partners enhances overall supply chain reliability.

Just-in-time (JIT) inventory management

Implementing JIT principles minimizes the amount of raw aluminum and finished parts held in inventory. This reduces storage costs, minimizes waste from obsolescence, and frees up capital. JIT requires highly reliable suppliers and precise forecasting.

Logistics and lead time optimization

Efficient logistics, from material delivery to finished part shipment, directly impacts overall project costs and timelines. Optimizing routes, choosing reliable carriers, and leveraging our Shenzhen location for global shipping can reduce transportation expenses and accelerate delivery.

Equipment Maintenance: Protecting Aluminum CNC Investment

Regular and proactive maintenance of CNC machinery is paramount for consistent performance, quality output, and long-term cost savings. Neglecting maintenance can lead to unexpected breakdowns, costly repairs, and significant production downtime.

Preventive maintenance schedules

Adhering to a strict preventive maintenance (PM) schedule for CNC machines helps identify and address potential issues before they escalate into major problems. This includes routine cleaning, lubrication, and inspection of critical components. PM extends machine lifespan and maintains precision.

Machine calibration and accuracy checks

Regular calibration of machine axes, spindle, and tool changers ensures that machines maintain their accuracy over time. Periodic checks verify the machine’s ability to hold tight tolerances, crucial for high-precision aluminum parts. Accurate machines reduce rework and scrap.

Coolant and lubrication management

Proper management of cutting fluids and lubricants is essential. Maintaining the correct concentration, pH level, and cleanliness of coolants prevents tool wear, improves surface finish, and extends tool life. Contaminated coolants can also lead to corrosion of machine components.

Expert Collaboration: Your Source for Aluminum Value

At ly-machining, our commitment extends beyond delivering parts; we partner with clients to optimize their projects from conception to completion. Leveraging our deep technical expertise and transparent processes ensures unparalleled value for aluminum CNC machining projects.

Technical consultation and DFM support

Our experienced engineering team provides comprehensive technical consultation, offering Design for Manufacturability (DFM) insights specific to aluminum. This collaborative approach helps clients refine designs for cost-effectiveness, performance, and manufacturability, reducing expensive iterations.

Transparent pricing and value engineering

We believe in clear, upfront pricing without hidden fees. Our value engineering approach focuses on identifying opportunities to reduce costs without compromising quality or functionality. We openly discuss material choices, process optimizations, and alternative solutions to maximize client value.

Case studies in cost-effective machining

We pride ourselves on a track record of success. For instance, a leading aerospace client achieved a 20% reduction in component costs while enhancing part strength, thanks to our collaborative DFM and process optimization. This demonstrates our ability to deliver tangible results.

Ready to transform your aluminum CNC machining costs and elevate your product quality? Connect with our expert engineering team today for a free design review and a personalized, transparent cost-optimization consultation.

Article Summary:

This article details the top 10 strategies for controlling costs and improving efficiency in aluminum CNC machining. It covers identifying hidden costs, implementing Design for Manufacturability, strategic material and tooling choices, process streamlining, and leveraging CAM software. Emphasis is placed on quality control, supply chain synergy, equipment maintenance, and the value of expert collaboration to achieve superior parts at optimized costs.

Frequently Asked Questions on Aluminum Machining

Q1: How early should DFM be integrated into the aluminum part design process to maximize cost savings?

A1: Integrating Design for Manufacturability (DFM) during the initial design phase offers the most significant cost reduction opportunities. Early DFM allows for fundamental design changes that avoid expensive tooling, minimize material waste, and streamline machining processes from the outset.

Retrofitting DFM principles later in the development cycle is often more costly and less effective, as design flexibility is reduced. Engaging with our engineering team during conceptual design ensures optimal material selection, feature simplification, and tolerance optimization for maximum cost-effectiveness.

Q2: What is the most common mistake companies make when trying to reduce aluminum CNC machining costs?

A2: The most common mistake is focusing solely on the lowest per-part unit price without considering the total cost of ownership (TCO). This often leads to compromising on material quality, tooling effectiveness, or supplier reliability, which can result in inconsistent part quality, increased rework, longer lead times, and ultimately higher overall project costs due to hidden expenses.

A holistic approach that balances material, process, quality control, and supply chain factors, as discussed in this guide, is essential for sustainable cost reduction without sacrificing performance.

Q3: How does ly-machining ensure transparent pricing for aluminum CNC projects?

A3: At ly-machining, we ensure transparent pricing by providing detailed, itemized quotes that clearly break down costs associated with material, machine time, tooling, setup, and any required post-processing or inspection. We actively engage in value engineering discussions, openly explaining how specific design choices or process optimizations impact the final cost.

Our approach is to foster a partnership where clients understand exactly where their investment is going and how we work collaboratively to achieve the most cost-effective and high-quality solution for their aluminum components.