Starting a new project with a CNC machining manufacturer often brings uncertainty. You need your precision parts delivered on schedule and exactly to spec, but the risk of production delays and quality control failures is always a concern. These setbacks can halt your entire assembly line, pushing back launch dates and inflating costs, forcing you to search for another supplier all over again. At ly-machining, we have built our entire process around five pillars of on-site management that guarantee production efficiency, ensuring your CNC machining project is predictable, reliable, and successful.

A high-performance CNC machining manufacturer guarantees production efficiency through five critical actions: 1) Comprehensive personnel training with performance-based incentives. 2) Proactive material management to prevent line-stopping shortages. 3) Rigorous preventative equipment maintenance for maximum uptime. 4) Integrated quality control, starting with first-article inspection. 5) Active on-site daily management for transparent communication and rapid problem-solving.

Now that you understand the core principles, let’s explore precisely how these elements protect your project. Ultimately, a promise of quality is only as strong as the process that supports it. Therefore, we want to give you a transparent look at the specific actions we take in each of these critical areas. Moreover, understanding this system will empower you to select the right CNC machining partner for your needs. Consequently, you can move forward with confidence, knowing exactly how we secure your project’s timeline and quality standards.

1. Empowering Our People: The Foundation of Productivity

We believe that our team is the true engine of our CNC machining capabilities. To ensure every member contributes to peak efficiency, we implement a thorough training program for all new employees, ensuring they master the required skills for their role. Furthermore, our compensation and evaluation system is designed for fairness and motivation; it directly rewards hard work and precision, ensuring that our team is fully engaged in delivering exceptional results for your project.

2. Proactive Material Management: Eliminating Bottlenecks

A production line can only move as fast as its material supply. To prevent delays, we utilize a dedicated material preparation area where all raw materials for the next day’s CNC turning and CNC milling operations are staged in advance. This simple but effective step eliminates the risk of production halting due to a missing component. This system also prevents the use of wrong, misplaced, or reworked materials, which is a common cause of batch defects in precision parts manufacturing.

| Feature | The Standard Manufacturer Approach | The ly-machining High-Efficiency Approach |

| Delivery Time | Often provides vague estimates; prone to unexpected delays. | Provides a clear, milestone-based schedule; proactive management minimizes delays. |

| Quality Control | Reactive inspection at the end of the process, risking full-batch rejection. | Integrated quality control with first-article inspection; rapid response to deviations. |

| Material Handling | Materials are sourced as needed, risking line stoppages from shortages. | All materials are prepared and staged 24 hours in advance, ensuring zero downtime from shortages. |

| Problem Response | Issues are often discovered late; communication can be slow and unclear. | On-site leaders identify and solve problems in real-time with transparent client communication. |

3. Peak Equipment Performance: The Engine of CNC Machining

Your project’s schedule depends on our machines running flawlessly. We refuse to accept intermittent stops and starts as a normal part of CNC machining. Our solution is a proactive equipment maintenance schedule, ensuring every machine is in optimal condition before a job begins. This focus on timely service and rapid coordination between our personnel, tooling, and materials maximizes uptime and ensures our equipment is a reliable asset, not a variable.

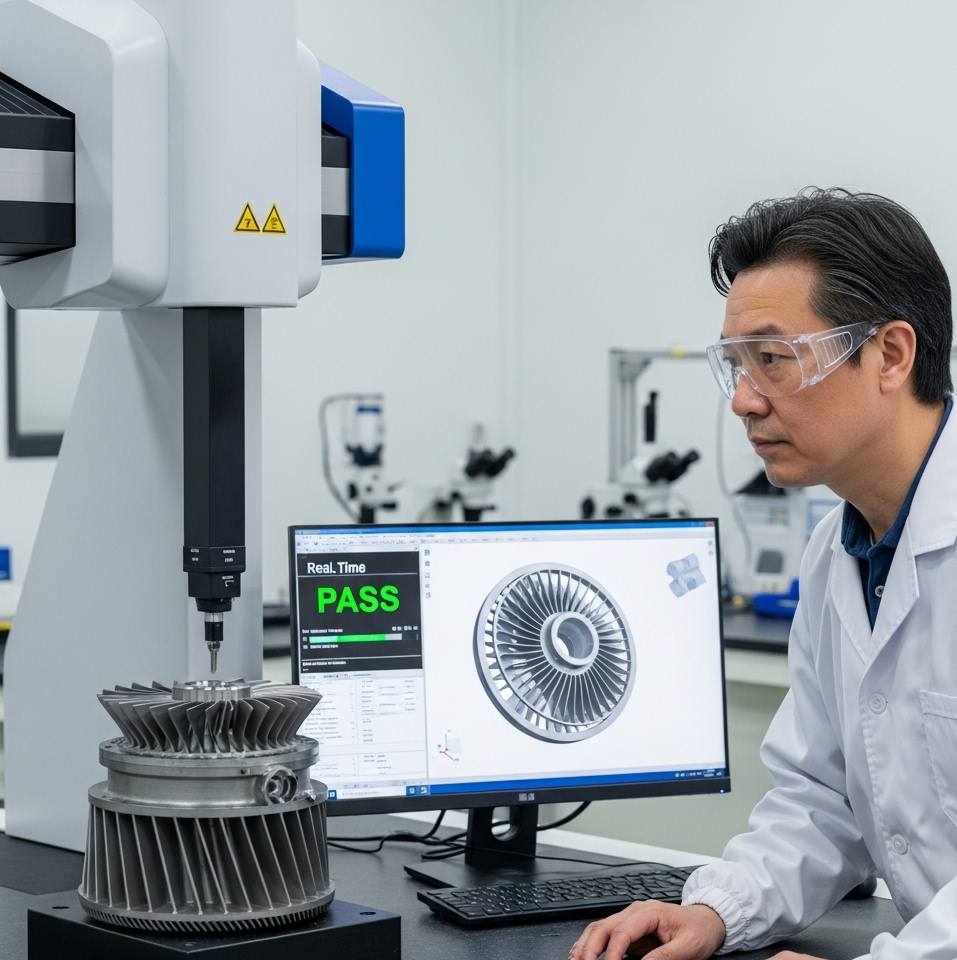

4. Integrated Quality Control: Right From the First Part

Quality cannot be an afterthought; it must be built into the process. Before any full-scale production run, the first part is rigorously inspected by both the team lead and a dedicated quality control specialist. Only after this first-article inspection is approved can we proceed with the batch. While quality deviations can occasionally occur in any complex CNC machining process, our strength lies in our rapid response, ensuring any issue is solved immediately to prevent production stoppages and project delays.

5. Active On-Site Leadership: Driving Daily Progress

Effective management happens on the factory floor, not from behind a desk. Our shift supervisors and managers lead daily pre-shift meetings and ensure a seamless handover between day and night shifts, eliminating delays caused by poor communication. You will find our leaders actively present on the production floor, where they can identify and solve problems as they happen. This hands-on approach is fundamental to how a responsive CNC machining manufacturer maintains high production efficiency.

FAQ

1. How can you prove this efficiency on my first project?

For new clients, we establish confidence through transparency. We provide a clear production schedule, define key milestones, and maintain open communication channels throughout the process. For critical projects, we can often accommodate a smaller trial run, allowing you to witness the quality and efficiency of our CNC machining service firsthand before committing to a larger batch.

2. What is your specific process if a quality issue is found in my batch of parts?

If an issue is detected, our rapid-response protocol is immediately activated. We first contain the affected parts to prevent them from moving forward. Then, our quality and production teams collaborate to perform a root cause analysis and implement a corrective action plan. As the client, you are informed promptly about the issue and our proposed solution, ensuring you are never left in the dark.

3. How does your approach to efficiency differ between CNC turning and CNC milling?

The core principles of managing people, materials, equipment, quality, and on-site leadership remain identical for both CNC turning and CNC milling. However, the specific tactics are tailored. For CNC turning, we focus heavily on optimizing cycle times and managing tool life for high-volume runs. For multi-axis CNC milling, efficiency gains come from advanced fixture design, optimized toolpaths, and minimizing setups for complex precision parts.