Quick Solution: Achieving aerospace tolerance control in 6061 aluminum CNC machining requires advanced technology, rigorous process control, and metrology for precision manufacturing of critical components.

In aerospace, precision isn’t just a specification—it’s safety. When your critical 6061 aluminum components demand tolerances measured in microns, what truly sets apart a reliable partner from a costly gamble? The answer lies in a deep understanding of material science, advanced machining techniques, and unwavering quality assurance.

As a source manufacturer, we understand that every aerospace component is a testament to engineering excellence. This article explores the specific challenges and our proven solutions for achieving unparalleled 6061 aluminum CNC precision, ensuring every part meets the most stringent aerospace tolerance control requirements.

The Core Challenge of 6061 Aluminum CNC

Material Properties and Machinability

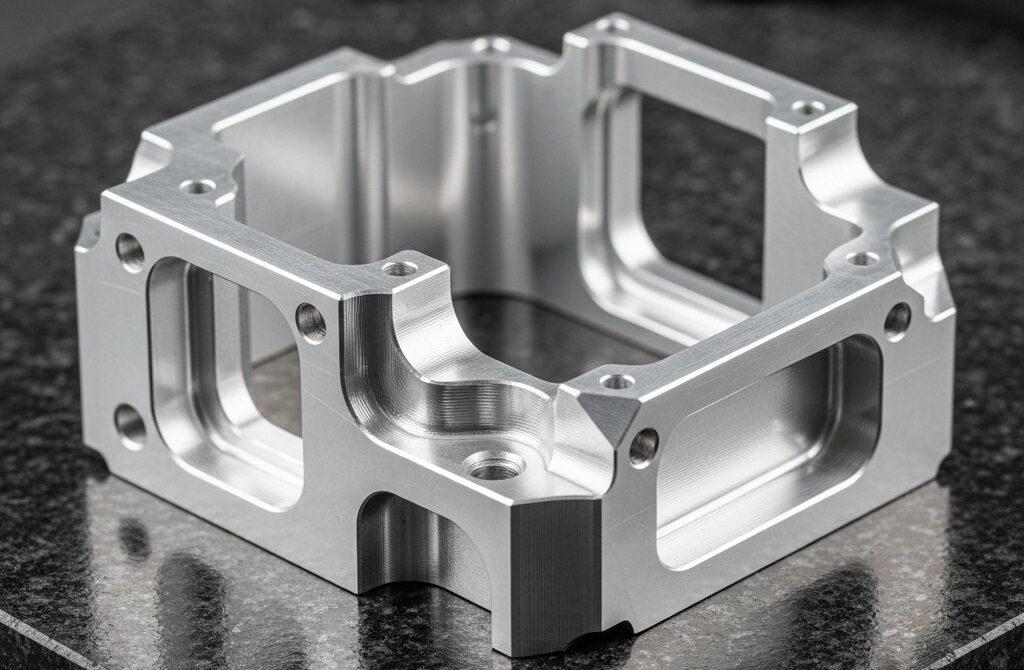

6061 aluminum is widely utilized in aerospace component manufacturing due to its excellent strength-to-weight ratio and corrosion resistance. However, its specific material properties present unique challenges for precision machining.

Its relatively soft nature can lead to burr formation and chip evacuation issues, particularly when attempting to hold tight tolerances. Managing these characteristics is critical for achieving the required surface integrity.

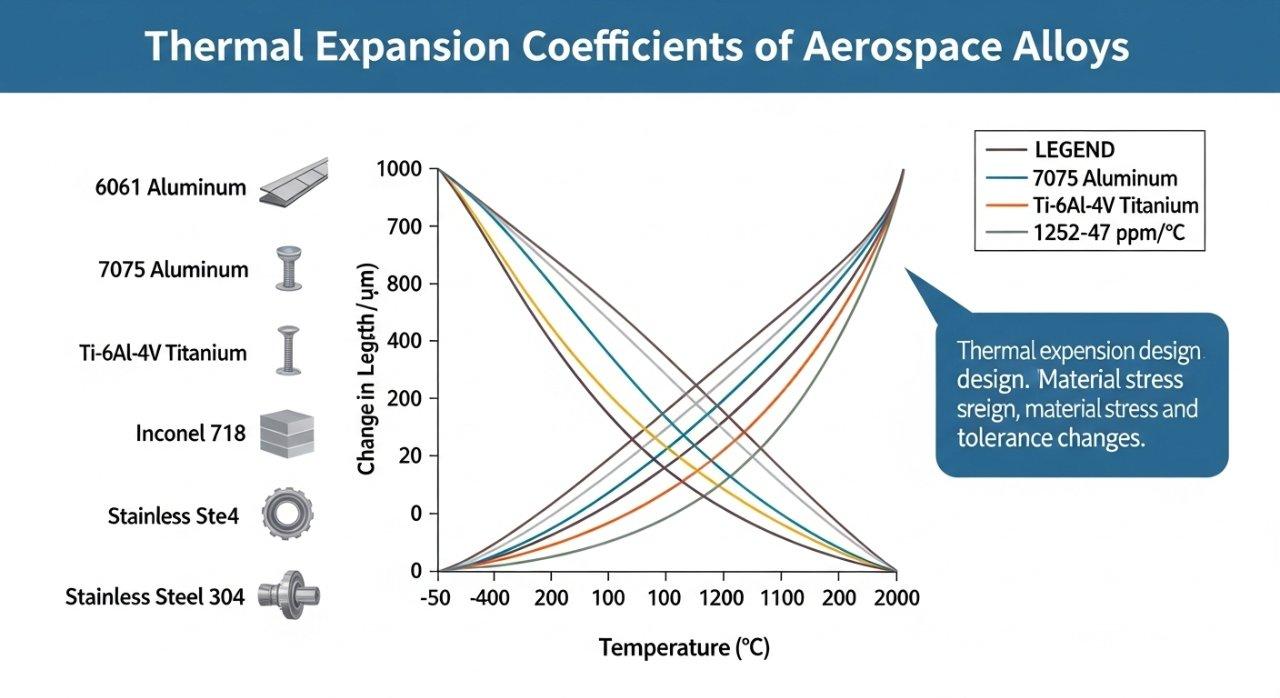

Thermal Stability Issues in Machining

A significant factor impacting 6061 aluminum CNC precision is thermal expansion. During machining, heat generation can cause the material to expand, leading to dimensional inaccuracies.

In our experience, controlling the thermal environment of both the workpiece and the machine tool is paramount for maintaining consistent aerospace tolerance control. This is especially true for intricate aerospace components.

Surface Integrity Requirements

Aerospace components demand not only tight dimensional tolerances but also superior surface integrity. Subsurface damage, micro-cracks, or poor surface finish can compromise fatigue life and structural performance.

Achieving the specified Ra or Rz values without introducing defects is a core aspect of precision machining 6061 aluminum. This requires careful selection of cutting parameters and tooling.

Achieving Machining Precision in 6061

Advanced CNC Machine Technology

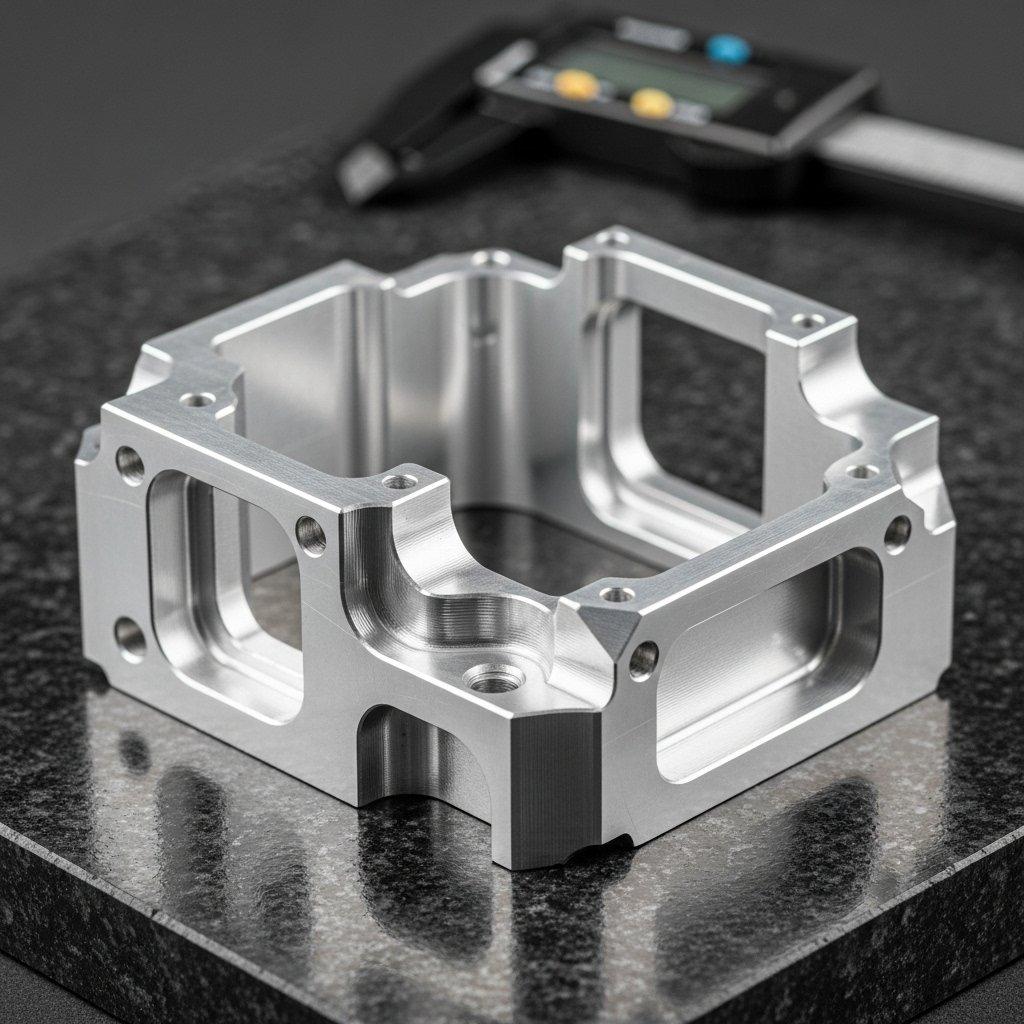

Our commitment to aerospace component manufacturing relies on state-of-the-art multi-axis CNC machining centers. These machines offer superior rigidity, thermal stability, and positional accuracy crucial for 6061 aluminum CNC precision.

Equipped with high-speed spindles and advanced control systems, they enable dynamic tool path optimization. This capability is essential for minimizing tool deflection and vibration, which directly impact tolerance.

Optimal Tooling and Cutting Strategies

The selection of tooling is critical for 6061 aluminum. We utilize specialized carbide tools with optimized geometries and coatings designed to reduce heat generation and improve chip evacuation.

Furthermore, we employ specific cutting strategies such as climb milling and high-feed machining to minimize cutting forces and achieve superior surface finishes. This approach directly contributes to aerospace tolerance control.

Fixture Design for Enhanced Accuracy

Precision machining starts long before the first cut. Our fixture designs are engineered to rigidly hold the 6061 aluminum workpiece, minimizing vibration and deformation during the machining process.

We often incorporate vacuum or hydraulic clamping systems and thermal compensation features. These bespoke fixtures are key to achieving repeatable high-precision results for complex aerospace components.

Environmental Control for Consistency

Maintaining a consistent manufacturing environment is non-negotiable for aerospace tolerance control. Our facilities feature temperature and humidity control systems.

These controls prevent ambient fluctuations from affecting machine accuracy and workpiece dimensions. This meticulous attention to environmental factors significantly enhances overall 6061 aluminum CNC precision.

Mastering Aerospace Parts Tolerance Control

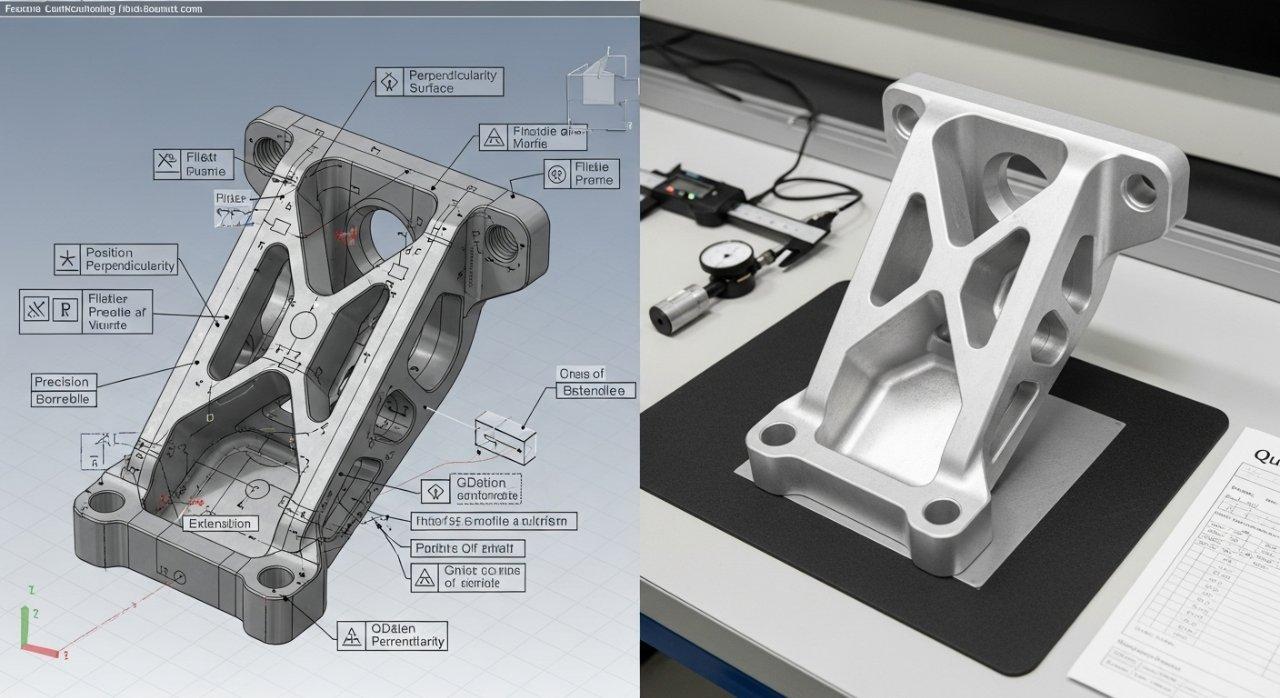

Understanding GD&T for Critical Features

Geometric Dimensioning and Tolerancing (GD&T) is the language of precision in aerospace component manufacturing. Our engineers are experts in interpreting and implementing complex GD&T callouts.

We translate these into precise machine movements and inspection protocols. This ensures that form, orientation, and location tolerances are consistently met across all critical features.

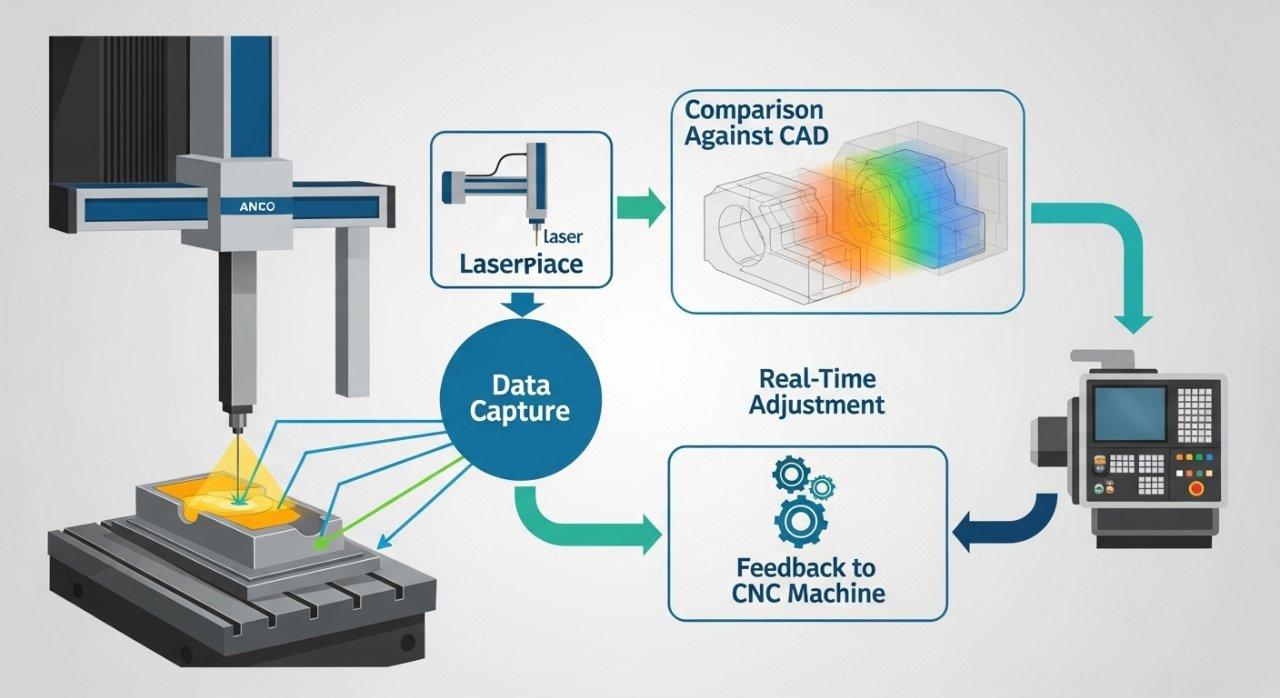

In-Process Metrology and Feedback Loops

To ensure 6061 aluminum CNC precision, we integrate in-process metrology techniques directly into our workflow. This includes on-machine probing and laser measurement systems.

These tools allow for real-time monitoring of dimensions and tool wear. Any deviation can be immediately corrected, forming a critical feedback loop for continuous aerospace tolerance control.

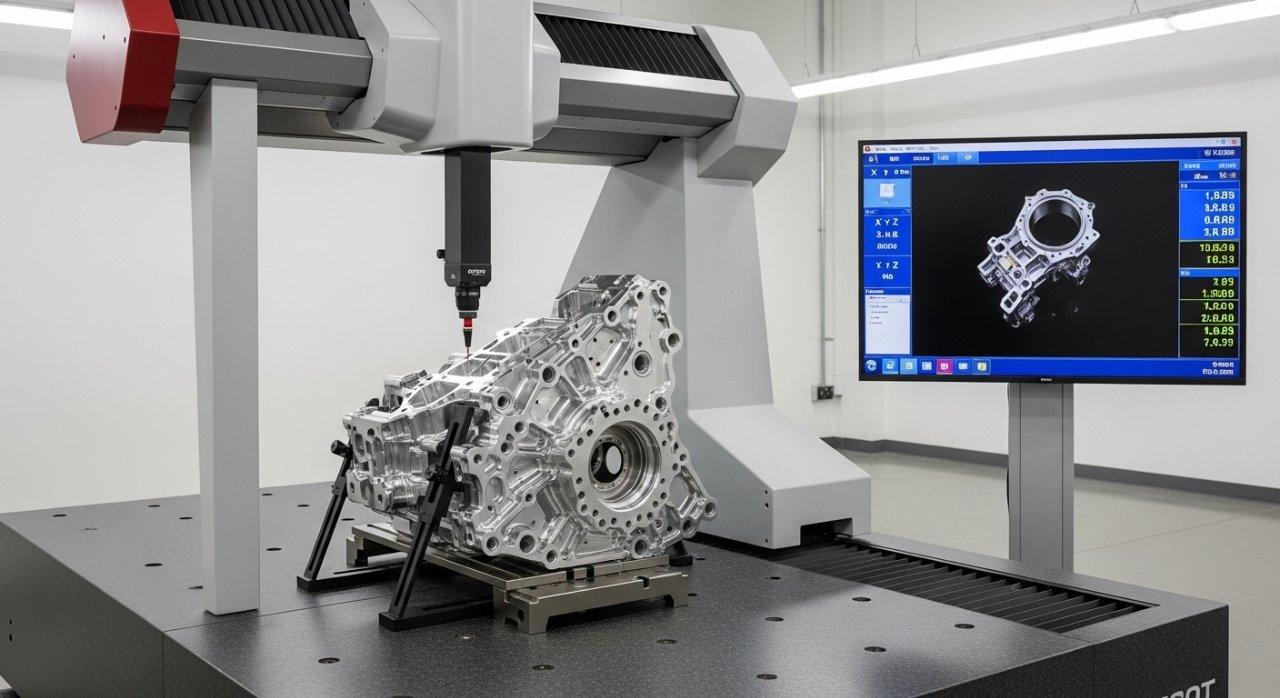

Post-Machining Quality Verification

Upon completion of machining, every aerospace component undergoes rigorous post-machining quality verification. This involves advanced metrology equipment in a climate-controlled inspection lab.

Our equipment includes Coordinate Measuring Machines (CMMs) with sub-micron accuracy and optical comparators. This comprehensive inspection confirms all GD&T specifications and ensures aerospace tolerance control.

Traceability and Certification (AS9100)

Complete material and process traceability is fundamental in aerospace component manufacturing. We maintain meticulous records for every 6061 aluminum batch and machining operation.

Our quality management system is AS9100 certified, demonstrating our adherence to the highest industry standards. This provides our clients with complete confidence and verifiable quality for their critical parts.

Our Expertise in Precision Aerospace 6061

Source Manufacturer Advantage for Quality

As a source manufacturer, we control every aspect of the 6061 aluminum CNC precision process from start to finish. This direct oversight translates into unparalleled quality and consistency for our clients.

There are no intermediaries, allowing for faster communication and problem-solving. This integrated approach is a cornerstone of our ability to deliver superior aerospace tolerance control.

Transparent Pricing, Value Engineering

We believe in transparent pricing models, ensuring our clients understand the cost drivers of their precision machining projects. Our engineers also engage in value engineering.

This collaborative process identifies opportunities to optimize designs for manufacturability (DFM) without compromising performance. We aim to achieve cost-efficiency while maintaining stringent aerospace tolerance control.

Deep Technical Insight and DFM Support

Our team comprises highly skilled engineers with deep technical insight into 6061 aluminum CNC machining. We offer comprehensive Design for Manufacturability (DFM) support.

Early collaboration with our clients’ design teams can significantly streamline the manufacturing process. This proactive approach helps predict and prevent potential issues, ensuring successful aerospace component manufacturing.

Case Study: Critical Component Success

Problem: An aerospace client required a critical structural bracket from 6061 aluminum with feature positional tolerances of +/-0.01mm over a 200mm length, as well as specific surface finish requirements. Their previous supplier struggled with repeatability.

Our Solution: We developed a multi-stage machining strategy, incorporating advanced thermal compensation during cutting and a custom vacuum fixture. In-process probing was implemented for real-time adjustments, and all parts underwent 100% CMM inspection under AS9100 protocols.

Result: Our approach not only met but consistently exceeded the required aerospace tolerance control, delivering a batch of components with a CpK of 1.67. This allowed the client to maintain their tight project schedule and eliminate costly rejections.

Partner for Uncompromising Aerospace Precision

Why Choose Our Factory for Your Needs

Choosing the right manufacturing partner for your aerospace components is a critical decision. Our factory offers unmatched expertise in 6061 aluminum CNC precision.

We combine cutting-edge technology with stringent quality control and a deep understanding of aerospace standards. This ensures your project’s success, offering peace of mind.

Next Steps for Your Project

We invite you to experience the difference of partnering with a dedicated source manufacturer. Let us demonstrate how our capabilities can elevate your aerospace component manufacturing.

Ensure your aerospace components meet uncompromising standards. Request a precision machining consultation today, or get a detailed quote for your 6061 aluminum project. Partner with a source manufacturer dedicated to aerospace excellence.

What is 6061 aluminum’s main challenge for precision?

In our experience, a primary challenge is managing its thermal expansion during high-speed 6061 aluminum CNC operations. This heat can cause temporary dimensional changes, making it difficult to maintain ultra-tight aerospace tolerance control.

Careful thermal management and appropriate cutting strategies are essential to counteract this effect. Without these measures, parts can fall outside critical specifications.

How do you ensure aerospace tolerance control?

We employ a multi-faceted approach. This includes advanced multi-axis CNC machines, optimized tooling, bespoke fixture design, and stringent environmental controls.

Crucially, we integrate in-process metrology for real-time feedback. Post-machining, 100% CMM inspection and AS9100 certified processes guarantee every aerospace component meets specified GD&T requirements.

Can you handle complex aerospace component manufacturing?

Absolutely. Our engineers specialize in interpreting complex GD&T specifications and offering Design for Manufacturability (DFM) support.

We have a proven track record of delivering intricate aerospace components. Our expertise in 6061 aluminum CNC precision is built to handle the most demanding designs and performance requirements.