Cost Efficiency and Flexibility

When I first started working with custom aluminum enclosures, I noticed that companies often hesitate to invest in smaller batch productions. They fear it might be too costly or inefficient compared to larger scales. However, I learned from a project I managed that smaller production runs can drastically reduce waste while allowing for more precise quality control. By focusing on custom production, you’re not locked into high volume numbers, which means you can order exactly what you need without incurring significant additional expenses. This flexibility allows you to innovate and adapt your products without breaking the bank.

Consider this: while a standard batch might require you to order thousands of pieces, custom machining allows for orders as small as a few units. For example, last year, I helped a client who needed unique aluminum enclosures for a prototype. Their first order was just fifty pieces. They were thrilled to save on costs since they only paid for what they needed, and they could fine-tune the design based on real-world testing.

Precision and Quality Assurance

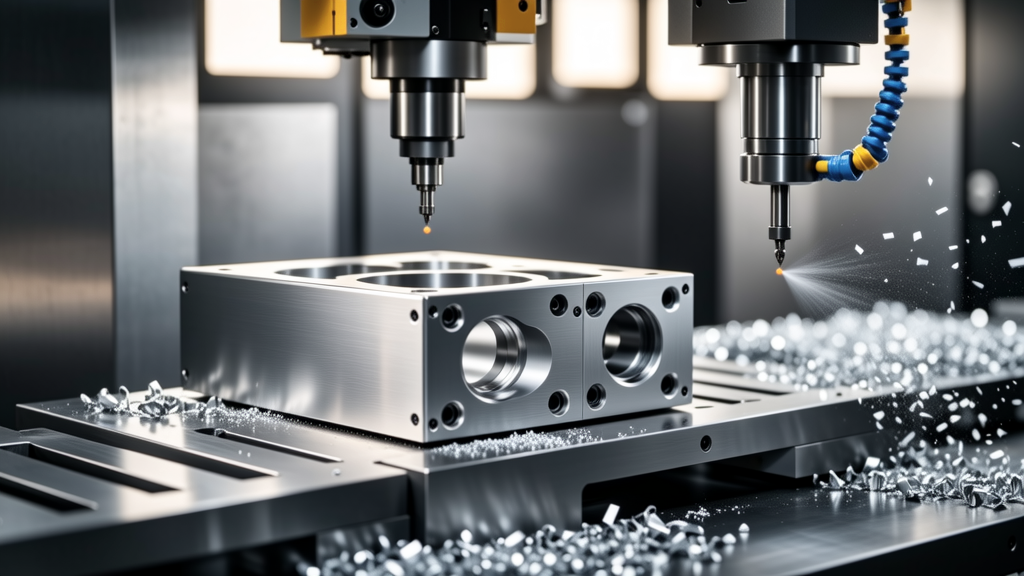

Speaking of design, one of the biggest draws of using CNC machining for custom aluminum enclosures is the precision it offers. With traditional manufacturing methods, achieving exact specifications can feel like a game of chance. CNC machining, however, ensures that every piece is produced consistently, which is particularly important when you’re working with components that need to fit together perfectly.

I remember working on a project where fitting issues arose because the original components from a cheaper manufacture weren’t precise enough. This resulted in increased rework costs and delays. This experience highlighted to me how critical the quality assurance aspect of CNC machining is. You’re not just getting a part; you’re getting a part that meets your exact specifications every time.

Furthermore, China has made incredible strides in advanced technology for CNC machining. Countries often overlook this aspect, but local manufacturers here have access to high-grade machinery and skilled labor. Hence, the end product is not only accurate but also built to last, which is a recurring theme in customer feedback we receive.

Shorter Lead Times

Another compelling benefit that stands out is the shortened lead times associated with custom aluminum enclosure CNC machining in China. Many clients come to us with tight deadlines, and standard manufacturing processes just don’t cut it. With CNC machining, we can often create high-quality prototypes very quickly and ramp up to full production without the lengthy wait.

For example, one of my colleagues worked with a tech startup that needed a quick turnaround on their product’s housings. They initially thought the three-month timeline was inevitable. However, through custom machining, we managed to complete their order in just six weeks without compromising quality! They were overjoyed, and the project’s success led to further collaboration.

Durability and Material Selection

Aluminum enclosures are known for their durability and lightweight nature, which makes them ideal for a variety of applications, especially in electronics and automotive industries. Custom CNC machining allows you to select from various types of aluminum alloys, tailored to meet specific performance requirements.

When you have the flexibility to choose not just the design but the material, you significantly enhance the functionality of your product. For instance, by opting for a specific alloy, you can improve heat resistance or corrosion resistance tailored to the environment in which the product will be used. As I’ve seen in multiple projects, the right material choice can make or break product longevity and reliability.

Conclusion

If you’re wondering whether to invest in custom aluminum enclosure CNC machining, consider the cost savings, precision, shorter timelines, and high-quality outcomes that can drastically improve your projects. If you need more insight or have specific queries, I encourage you to reach out with your questions so we can explore options that fit your unique needs.

What is the cost advantage of custom aluminum enclosure CNC machining?

Custom aluminum enclosure CNC machining can significantly reduce costs, especially for smaller batch productions. You’re not forced to order thousands of pieces, which saves you money and inventory space.

For instance, many companies have found that ordering custom pieces in smaller runs, as few as 50 to 100 units, allows them to allocate resources more effectively without wasting materials.

How does custom machining ensure precision and quality?

The precision provided by CNC machining ensures that each aluminum enclosure is manufactured to exact specifications. This level of accuracy is often not achievable with traditional production methods.

My own experiences have shown that using CNC machining can reduce fitting issues and rejects, leading to higher quality products that meet customer expectations right off the bat.

Can custom aluminum enclosures be produced quickly?

Yes, one of the standout features of custom aluminum enclosure CNC machining is its ability to drastically cut down on lead times. Many projects that initially seem to require long timelines can be completed much faster.

For example, we recently took on a project where we managed to produce an initial order in just six weeks, instead of the usual three months, which was a game changer for the client.

What materials can be used in custom aluminum CNC machining?

When it comes to material selection, custom aluminum CNC machining offers flexibility to choose from various aluminum alloys tailored to specific needs.

This means you can select materials that enhance properties like heat resistance or corrosion protection based on the intended application of the enclosure, leading to a better-performing product overall.

Is durability a key benefit of aluminum enclosures?

Absolutely! Aluminum enclosures are known for their durability and lightweight nature, making them suitable for a variety of applications, especially in electronics and automotive industries.

Choosing the right alloy during the machining process not only ensures a sturdy enclosure but also extends the life of the product, which can be crucial for long-term performance.