You’re probably wondering what’s new in the aluminum enclosure CNC machining scene in China, right? Let me tell you, there are some seriously exciting trends shaping the future of this industry. As a CNC manufacturer at ly-machining, I’ve seen firsthand how these shifts can revolutionize manufacturing processes and improve efficiency.

Automation and Smart Technologies

First off, let’s chat about automation and smart technologies. CNC machining is no longer just about precision machining; it’s evolving into a more automated and intelligent process. For example, I’ve noticed many companies are integrating IoT (Internet of Things) sensors into their machines. This allows for real-time monitoring of production, enabling operators to catch issues before they escalate. I helped a client implement IoT technology last year, and they reported a 30% reduction in downtime. Isn’t that impressive?

Furthermore, the integration of AI in machining processes means that machines are getting “smarter.” They can now analyze production data and suggest adjustments in real-time to optimize efficiency and reduce waste. This isn’t just a gimmick; it’s about improving the bottom line. As I’ve seen, smart manufacturing helps cut costs while enhancing product quality.

Sustainability Practices

Another trend that’s picking up steam is sustainability. In today’s market, companies are becoming increasingly aware of their environmental impact. Aluminum production is energy-intensive, and machining it can produce a significant amount of waste. That’s why many manufacturers are now adopting greener practices. For instance, a friend of mine who runs an aluminum machining facility started recycling scrap aluminum and investing in energy-efficient machines. This not only reduced their carbon footprint, but also saved them money on raw materials.

From what I gather, eco-friendly practices aren’t just good for the planet; they’re also becoming more important for consumers. More and more customers prefer to work with companies that have sustainable practices in place, and this trend isn’t going away anytime soon.

Precision and Customization

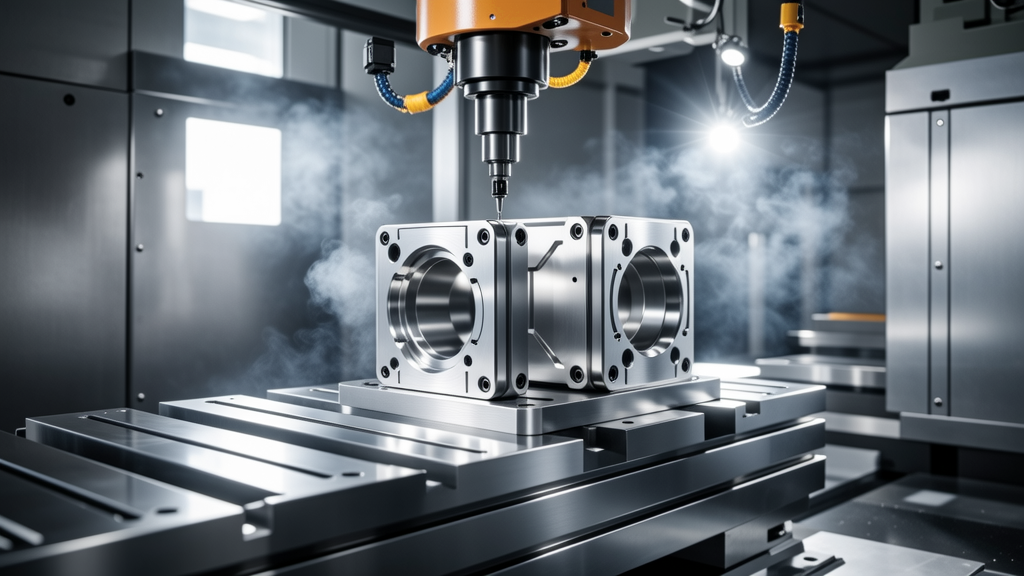

Now let’s not forget about the demand for precision and customization. Gone are the days when one-size-fits-all solutions were acceptable. Today, customers are looking for tailored products that meet their specific needs. This has led to a rise in the use of advanced technologies, such as 5-axis CNC machines, which can create intricate designs and complex geometries. This level of precision allows manufacturers to meet exact specifications and stay ahead of the competition.

For instance, I remember a case where a client needed specific aluminum enclosures for a tech device. By using multi-axis machining, we were able to produce custom parts that fit perfectly, leading to a 40% increase in their production efficiency. It’s remarkable how much precision can impact overall productivity.

Conclusion of Trends

In summary, the aluminum enclosure CNC machining industry in China is undergoing significant transformations driven by automation, sustainability, and the demand for precision. These trends aren’t just fads; they represent the future of manufacturing. If you’re involved in this industry, keeping an eye on these changes can help you stay relevant and competitive. If you have any thoughts or experiences related to these trends, feel free to share!

What are the main benefits of automating CNC machining processes?

Automating CNC machining processes can significantly boost efficiency and reduce operational costs. For instance, companies that incorporated IoT technology into their systems have reported up to a 30% reduction in downtime, which can be a game-changer for productivity.

Moreover, automated systems can manage tasks more quickly and accurately compared to manual labor, minimizing errors and waste. This means that businesses can produce higher-quality parts while using fewer resources.

How does sustainability impact CNC machining practices?

Sustainability has become a major focus for many manufacturers, especially in aluminum CNC machining. Companies are increasingly adopting eco-friendly practices, such as recycling scrap aluminum and investing in energy-efficient machinery.

This shift not only helps to lower the environmental footprint but can also lead to cost savings in materials. Many businesses are realizing that being sustainable isn’t just good for the planet; it’s also good for their reputation and profits.

What role does precision play in aluminum enclosure manufacturing?

Precision is crucial in aluminum enclosure manufacturing, especially when clients demand tailored solutions. The use of advanced technologies like 5-axis CNC machines allows manufacturers to create complex geometries with incredible accuracy.

For example, a business that needed specific designs for tech devices saw a 40% improvement in production efficiency after adopting multi-axis machining. This kind of precision ensures that products meet the exact needs of customers, which helps businesses gain a competitive edge.

What are some key technologies changing the CNC machining landscape?

Key technologies such as IoT, AI, and advanced automation are transforming the CNC machining landscape today. These advancements enable real-time monitoring of production processes and empower machines to make adjustments on the fly based on real-time data.

By adopting these technologies, companies can enhance efficiency by decreasing machine downtime and improving the quality of their products, leading to better customer satisfaction in the long run.

How important is customization in CNC machining today?

Customization is incredibly important in today’s CNC machining market. Clients are no longer satisfied with generic solutions; they want products that cater specifically to their needs. This demand for customization has led manufacturers to invest in advanced technologies that facilitate bespoke designs.

By providing tailored solutions, companies can significantly improve client satisfaction and loyalty, which in turn boosts their business growth. It’s clear that being able to customize parts is a key trend to follow now and in the coming years.