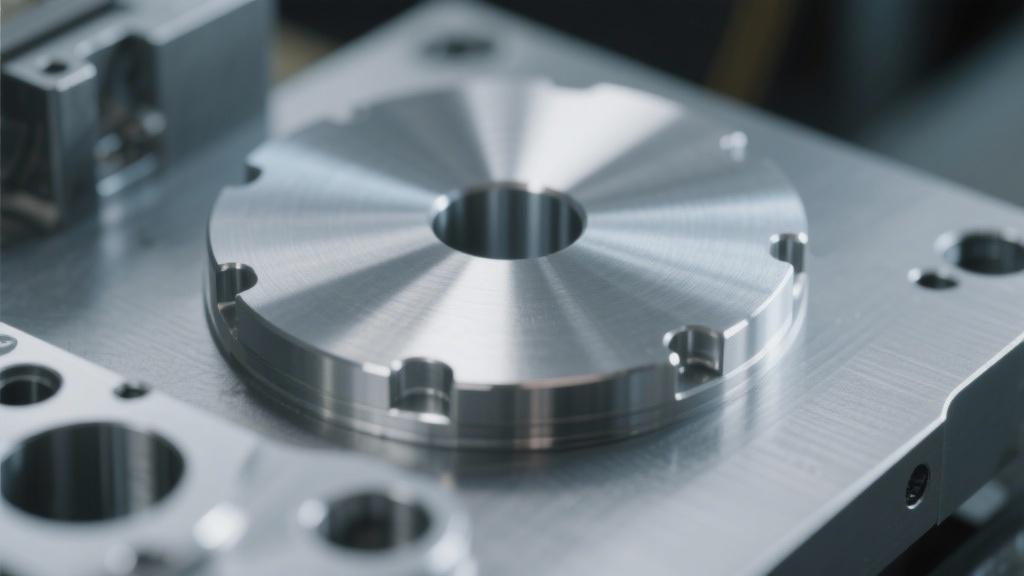

Additionally, we highlight common challenges faced during machining and provide practical tips to overcome them, ensuring an optimal finish. Whether you’re new to CNC machining or looking to refine your technique, this comprehensive guide offers valuable insights that can enhance your production efficiency and ensure your parts meet high standards. Dive in to discover the critical influences on surface finish, and unlock the potential for superior quality in your aluminum machining projects.

在CNC铝加工中,表面质量的影响因素有很多。在为你的项目选择合适的铝零件时,了解这些因素对实现理想表面效果的重要性至关重要。在本章,我们将深入探讨影响CNC铝件表面光洁度的主要因素,从而帮助你优化加工过程,提高成品的整体质量。

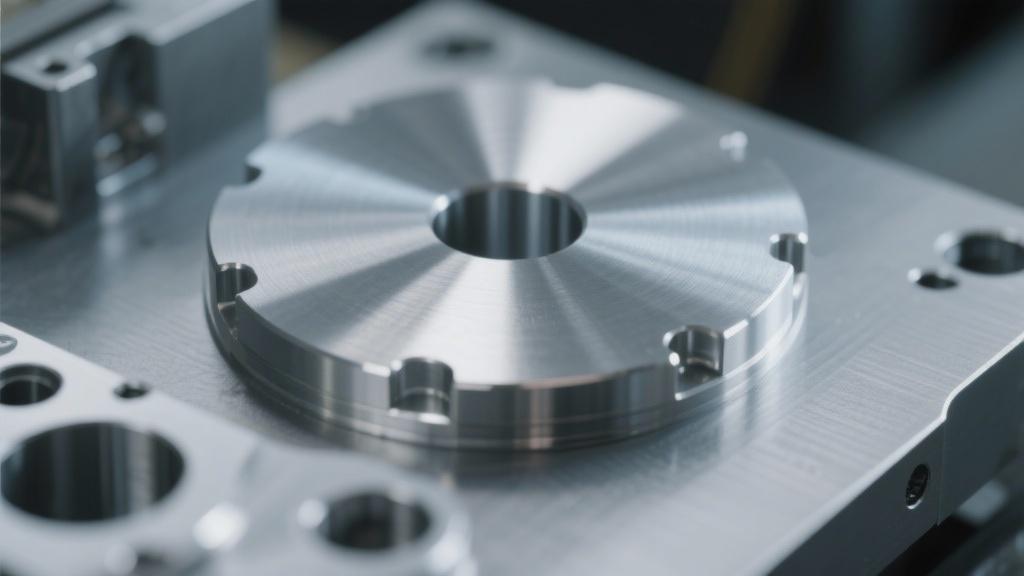

Tooling and Tool Wear

工具的选择和磨损状况,对CNC铝加工中表面 finish 影响极大。应用不同类型的刀具,比如高速钢(HSS)和硬质合金(carbide),会产生不同的表面效果。更换磨损的刀具和正确选择切削参数(如进给速度和切削速度)在确保最佳表面光洁度方面至关重要。使用磨损程度较低的刀具,可以显著减少表面粗糙度并提高最终产品的一致性。

| Tool Type | Material | Average Tool Life | Surface Finish Quality |

|---|---|---|---|

| End Mill | Carbide | 200-300 mins | Excellent |

| End Mill | HSS | 100-150 mins | Good |

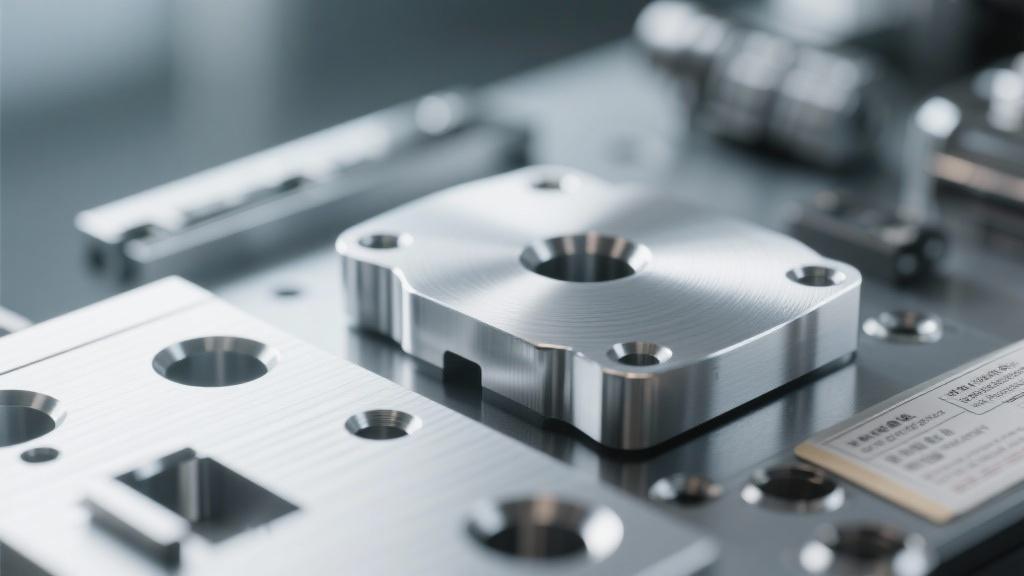

Machining Parameters

切削速度、进给速度和切削深度等加工参数对表面质量有显著影响。过高的切削速度可能导致热损伤,而过低的切削速度可能会导致表面粗糙。在设置这些参数时,要考虑材料的特性以及最终应用的要求。特别注意不要过度加工,以避免表面缺陷,如振动造成的沟槽或划伤。

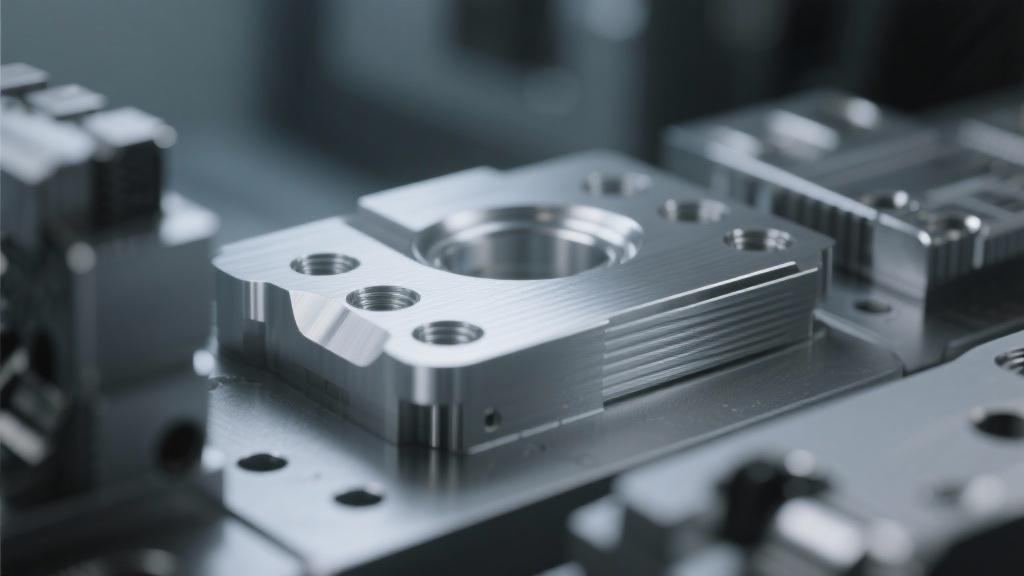

Material Properties

铝合金的类型和合金成分也会显著影响表面质量。不同的铝合金具有不同的切削特性,有些可能容易划伤,而有些则更适合高精度加工。 6061铝合金常用于加工与强度、耐腐蚀性相关的应用,但在加工时需要适当调整参数以获得最佳表面效果。

Environment and Cooling Method

加工环境条件和冷却方法同样不可忽视。使用适当的冷却液或油,可以降低刀具摩擦和热量,进一步改善表面光洁度。不恰当的冷却可能导致氧化或热变形,这将影响最终产品的外观和性能。确保车间通风良好,使用合适的工具,可以减少对表面质量的负面影响。

了解这些影响因素后,你可以更有效地规划你的CNC铝加工项目,从而提高产品的表面质量。通过优化刀具选择、加工参数、材料特性和冷却方法,你将能够获得较高的表面光洁度和一致性。

What tooling choices should I consider for better surface finish?

Choosing the right tooling is crucial for achieving a high-quality surface finish on CNC machined aluminum parts. Options like carbide end mills usually yield better results compared to HSS tools due to their durability and cutting efficiency.

Keep in mind that regularly replacing worn tools enhances surface finish quality, as dull tools can create imperfections and increase roughness.

How do machining parameters affect the final product quality?

Machining parameters like cutting speed, feed rate, and depth of cut significantly impact surface finish. For instance, maintaining cutting speeds between 1000-2000 RPM typically results in smoother surfaces.

Adjusting these parameters according to material specifics can prevent issues like overheating or excessive roughness, leading to a more polished end product.

What materials are best for achieving optimal surface finish?

The type of aluminum alloy you choose greatly influences surface quality. Alloys like 6061 or 7075 are commonly preferred due to their excellent machinability and consistent finish when processed correctly.

Understanding the specific properties of each alloy helps you tailor your machining strategy for the best results.

How does the cooling method affect the machining process?

Effective cooling is vital during machining to prevent overheating, which can degrade surface quality. Utilizing proper cutting fluids or oils can help keep temperatures in check.

It’s essential to select a cooling method that suits your specific machining conditions to maintain the integrity and finish of your aluminum parts.

What common challenges should I be aware of when machining aluminum?

Common challenges include tool wear, overheating, and surface defects such as scratches. Monitoring tool condition and adjusting machining parameters can mitigate these issues.

Understanding these challenges allows you to proactively implement solutions, ensuring a smoother machining process and a better quality final product.