Understanding CNC Machined Aluminum

CNC machining transforms raw aluminum into precise, lightweight aluminum components, crucial for industries demanding high performance. As a leading aluminum supplier, we leverage advanced computer numerical control services to deliver superior quality and reliability.

Unlock the full potential of your designs with CNC machined aluminum. Discover why this versatile material, combined with precision manufacturing, is the backbone of modern engineering – and how partnering with an expert source manufacturer makes all the difference.

In today’s fast-paced industries, the demand for components that are both strong and light is constant. Aluminum, with its unique properties, stands out as a material of choice. Its adaptability makes it ideal for a vast array of applications.

This guide will delve into the intricacies of CNC machining aluminum, exploring its advantages, common alloys, and essential processes. We will showcase how our expertise ensures your projects achieve unparalleled precision and quality.

The Power of CNC Aluminum Machining

Why Aluminum Dominates Precision Manufacturing

Aluminum’s exceptional strength-to-weight ratio is a primary reason it dominates precision manufacturing. This characteristic is vital for applications where reducing mass without compromising structural integrity is paramount.

In our experience, clients frequently choose aluminum for projects requiring both durability and energy efficiency. Its inherent properties make it highly desirable across diverse sectors.

How CNC Machining Transforms Aluminum into Parts

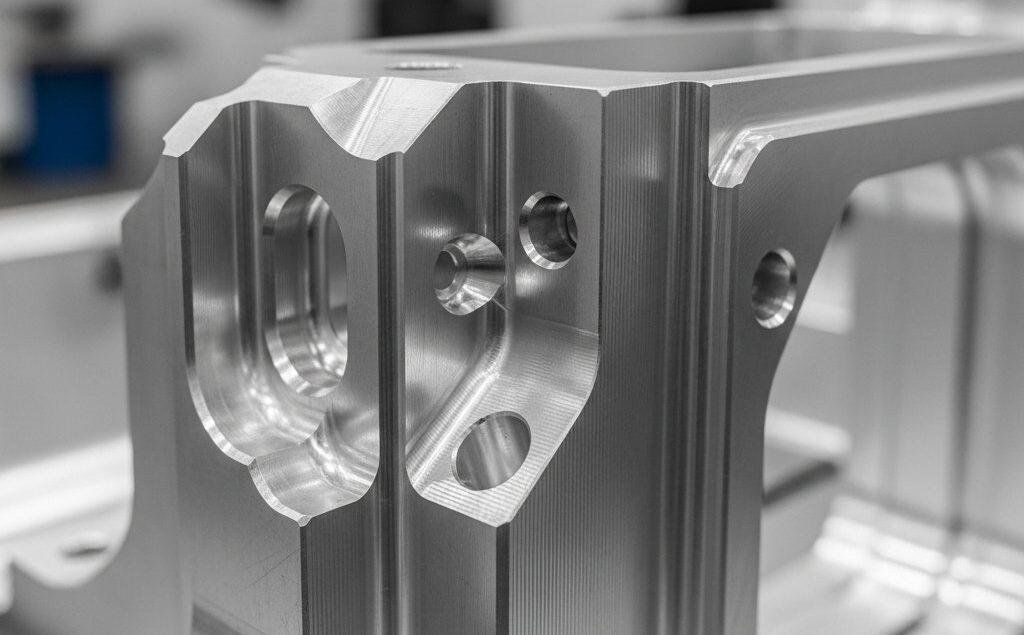

Computer Numerical Control (CNC) machining is the process that precisely shapes aluminum stock into complex components. It uses computer-aided design (CAD) and manufacturing (CAM) software to guide cutting tools with extreme accuracy.

This automation ensures consistent quality and repeatability, essential for high-volume production of intricate aluminum parts. It allows for the creation of geometries impossible with manual methods.

What is CNC Aluminum Machining?

Defining CNC Aluminum Machining: Precision and Process

CNC aluminum machining involves using automated tools to remove material from an aluminum workpiece. This process is driven by digital instructions, achieving micron-level precision and complex designs.

The versatility of CNC machining allows for a wide range of operations, from milling and turning to drilling, all controlled by a computer program. This ensures accuracy that manual methods cannot match.

Key Properties of Aluminum for Machining

Aluminum possesses excellent thermal conductivity, is highly corrosion-resistant, and non-magnetic. These attributes make it suitable for environments where other metals would fail.

Its softness relative to steel, combined with good chip formation, generally makes aluminum very easy to machine. However, specific alloys present their own unique challenges and opportunities.

Advantages of CNC Machining Aluminum Parts

Superior Machinability for Aluminum Components

Aluminum’s inherent softness allows for faster cutting speeds and feed rates compared to tougher metals. This translates directly into reduced cycle times and lower production costs.

In our factory, we can achieve very tight tolerances and smooth surface finishes on aluminum parts efficiently. This is a significant advantage for components requiring high precision.

Material Benefits: Strength, Corrosion, Aesthetics

CNC machined aluminum parts offer an impressive strength-to-weight ratio, making them ideal for aerospace and automotive applications. This is why it’s often referred to as lightweight aluminum.

Its natural oxide layer provides excellent corrosion resistance, which can be further enhanced through various surface treatments. Additionally, aluminum offers a clean, modern aesthetic.

Environmental & Cost Efficiency of Aluminum

Aluminum is 100% recyclable without loss of quality, contributing to its environmental sustainability. The energy required for recycling is significantly less than for primary production.

Furthermore, its machinability often leads to cost-effective production, especially when considering tooling longevity and reduced energy consumption during the machining process.

Common Aluminum Alloys for CNC Machining

Wrought vs. Cast Aluminum: Choosing the Right Alloy

Wrought aluminum alloys are mechanically worked, resulting in higher strength and ductility. They are preferred for CNC machining due to their fine grain structure and consistent properties.

Cast aluminum alloys are formed by pouring molten metal into molds. While more cost-effective for complex shapes in high volumes, their inherent porosity and varied grain structure make them less ideal for high-precision CNC machining.

6061-T6 Aluminum: Versatility and Strength

6061-T6 is perhaps the most widely used general-purpose aluminum alloy for CNC machining. It offers a good balance of strength, weldability, corrosion resistance, and machinability.

In our operations, we often recommend 6061-T6 for structural components, frames, and fixtures across various industries. It performs reliably in diverse applications.

7075-T6 Aluminum: High-Strength Aerospace Applications

Known as one of the strongest aluminum alloys, 7075-T6 offers exceptional tensile strength, comparable to many steels. This makes it a preferred choice for high-stress aerospace components.

While more challenging to machine than 6061, its superior strength-to-weight ratio justifies the effort for critical parts. It is a premium material for lightweight aluminum applications.

5052-H32 Aluminum: Corrosion Resistance for Sheets

5052-H32 aluminum exhibits excellent resistance to saltwater corrosion and marine environments. It is often supplied in sheet form and is highly formable.

This alloy is not typically used for highly complex CNC machined parts but rather for enclosures, panels, and brackets where environmental resistance is key. We process many aluminum sheets of this alloy.

2024-T3 Aluminum: Fatigue Resistance for Parts

2024-T3 aluminum is a high-strength alloy known for its superior fatigue resistance. It is often used in aircraft structures where components are subjected to repeated stress cycles.

While it has fair machinability, its corrosion resistance is lower than some other alloys, often requiring protective coatings. It creates robust aluminum parts for demanding uses.

Key CNC Machining Processes for Aluminum

Precision CNC Milling of Aluminum Parts

CNC milling uses rotating multi-point cutting tools to remove material from a stationary aluminum workpiece. This process is highly versatile, capable of creating complex 2D and 3D geometries.

With 3-axis, 4-axis, and 5-axis CNC milling, we can achieve intricate features, deep cavities, and excellent surface finishes on diverse aluminum parts. This is fundamental to our CNC machining services.

Efficient CNC Turning for Cylindrical Aluminum

CNC turning, typically performed on a lathe, involves rotating the aluminum workpiece against a stationary cutting tool. It is ideal for producing cylindrical or conical aluminum components.

This process is highly efficient for shafts, bushings, and other parts with rotational symmetry. Our precision turning capabilities ensure exceptional concentricity and surface quality.

Essential CNC Drilling Techniques for Aluminum

CNC drilling creates holes in aluminum workpieces with high accuracy and repeatability. Different drill types and techniques are employed based on hole diameter, depth, and desired surface finish.

Effective chip evacuation and coolant application are crucial when drilling aluminum to prevent material buildup and ensure tool longevity. This attention to detail is part of our standard operating procedure.

Other Processes for Aluminum Components

Beyond milling, turning, and drilling, our CNC machining facilities offer additional capabilities. These include tapping for threaded holes and reaming for highly precise internal diameters.

We also perform specialized operations like pocketing and profiling to create custom aluminum components. Our diverse capabilities ensure we can meet varied project requirements.

Optimizing Tools & Techniques for CNC Aluminum

Selecting Proper Tooling for Aluminum Machining

Choosing the right cutting tools is critical for efficient CNC aluminum machining. We primarily use sharp, high-positive rake angle tools, often with polished flutes, to prevent chip welding.

Carbide tools are generally preferred for their hardness and wear resistance, especially with high-speed machining. Coatings like TiCN can further enhance tool life and performance.

Overcoming CNC Aluminum Machining Challenges

A common issue we see is chip evacuation. Aluminum tends to produce long, stringy chips that can clog tools and damage surfaces. We address this with optimized tool paths, high-pressure coolants, and proper chip breakers.

Another challenge is heat generation. While aluminum dissipates heat well, excessive heat can lead to thermal expansion and dimensional inaccuracies. Our robust cooling systems and machining strategies mitigate this.

Leveraging CAM Software for Aluminum Parts

Advanced CAM (Computer-Aided Manufacturing) software is indispensable for optimizing tool paths and machining parameters for aluminum parts. It allows us to simulate the process, identify potential collisions, and refine efficiency.

This technology helps us achieve superior surface finishes and minimize cycle times. It is a core part of our expertise in delivering high-quality CNC machining for aluminum projects.

Finishing Options for CNC Aluminum Parts

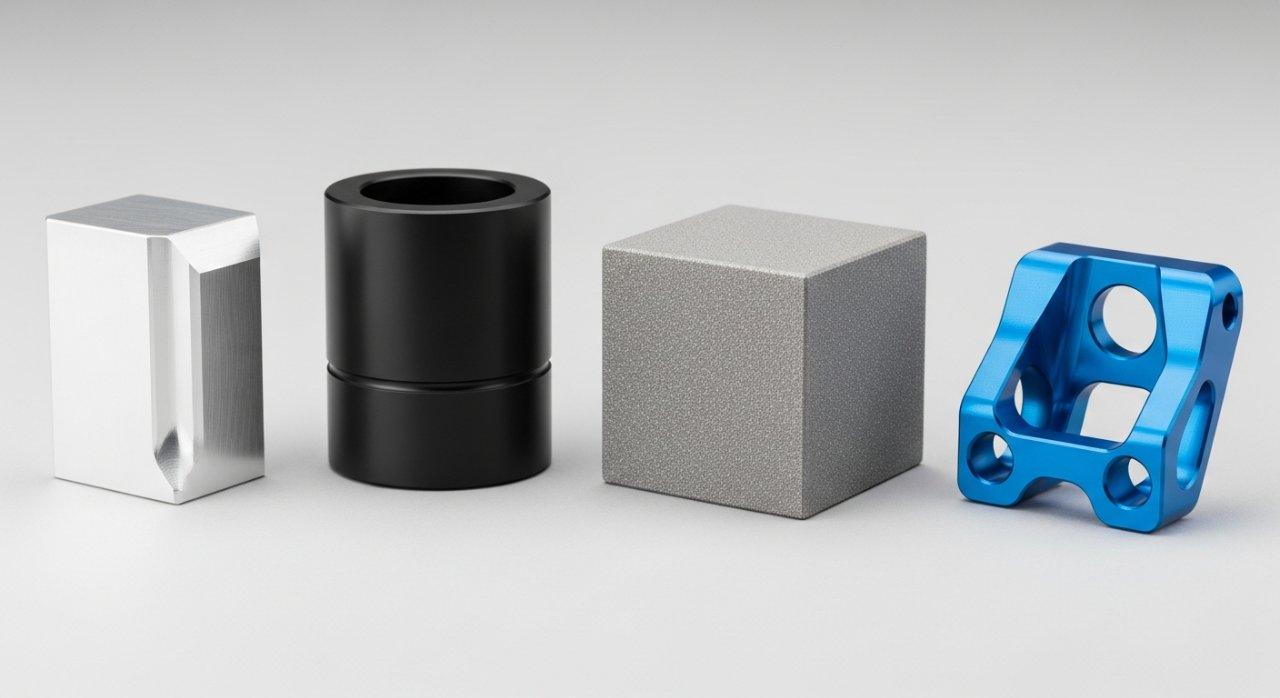

Anodizing: Enhancing Aluminum’s Durability & Look

Anodizing is an electrochemical process that forms a protective, decorative oxide layer on the surface of aluminum parts. It significantly improves corrosion resistance and wear properties.

It also allows for various aesthetic finishes, including a wide range of colors. Type II (sulfuric acid anodizing) and Type III (hard coat anodizing) are common choices, offering different levels of hardness.

Bead Blasting for Uniform Aluminum Surface

Bead blasting involves propelling fine glass beads at the aluminum surface to create a uniform, matte finish. This process can mask minor machining marks and prepare the surface for subsequent coatings.

It provides a consistent, non-reflective aesthetic that many clients prefer for their aluminum components. It is an excellent pre-treatment step.

Nickel Plating to Improve Aluminum Hardness

Electroless nickel plating applies a uniform layer of nickel alloy onto aluminum parts, enhancing their hardness, wear resistance, and corrosion protection. This is particularly useful for demanding industrial applications.

It provides a highly durable surface, especially when the aluminum component needs to withstand abrasive environments.

Powder Coating for Robust Aluminum Protection

Powder coating applies a protective polymer finish electrostatically, which is then cured under heat. This creates a hard, durable layer highly resistant to chipping, scratching, and fading.

It offers excellent protection against environmental elements and is available in a vast array of colors and textures, making it a versatile option for aluminum parts.

Industries Using CNC Machined Aluminum

Aerospace & Aviation: Lightweight Aluminum Components

The aerospace industry heavily relies on lightweight aluminum components for aircraft fuselages, wings, and engine parts. The strength-to-weight ratio is critical for fuel efficiency and performance.

Our expertise in precision CNC machining for these demanding specifications makes us a trusted aluminum supplier to this sector.

Automotive Sector’s Demand for CNC Aluminum

The automotive industry utilizes CNC aluminum for engine blocks, chassis components, suspension parts, and custom racing components. Lightweighting vehicles improves fuel economy and handling.

We provide high-quality CNC aluminum solutions that meet the stringent performance and durability requirements of modern automotive design.

Consumer Electronics & Aluminum Applications

From smartphone casings to laptop enclosures and camera bodies, aluminum’s aesthetic appeal, heat dissipation properties, and lightweight nature are highly valued in consumer electronics.

Our precision CNC machining capabilities ensure sleek designs and robust protection for delicate internal components.

Medical & Dental: Precision Aluminum Parts

The medical and dental fields require incredibly precise and often sterilizable components. CNC machined aluminum is used for surgical instruments, diagnostic equipment housings, and prosthetics.

The material’s biocompatibility, coupled with our tight tolerance capabilities, makes it an ideal choice for these critical applications.

Industrial Machinery Using Robust Aluminum

Industrial machinery, automation equipment, and robotics frequently incorporate robust aluminum components. Its combination of strength, heat dissipation, and corrosion resistance ensures reliable performance in harsh environments.

We supply complex aluminum parts for these systems, contributing to their efficiency and longevity.

Partner with a CNC Aluminum Supplier

Why Our Expertise Matters for Your Aluminum Projects

As an experienced aluminum supplier and source manufacturer, we offer deep technical expertise in CNC machining aluminum. Our engineers provide valuable DFM (Design for Manufacturability) insights to optimize your designs.

We pride ourselves on transparent communication, consistent quality control, and adherence to industry standards like ISO 9001 and AS9100. This ensures your aluminum projects are handled with utmost professionalism.

Get a Transparent Quote for Your Aluminum Parts

We understand the importance of clear, competitive pricing. Our quoting process for aluminum parts is straightforward, detailing all costs without hidden fees.

You will receive a comprehensive breakdown, allowing you to budget effectively and confidently for your CNC machining needs.

Ready for Precision? Contact Our CNC Machining Experts

Whether you require lightweight aluminum prototypes or high-volume production of complex aluminum components, our team is ready. We are your trusted partner for superior CNC machining services.

Our commitment to precision and customer satisfaction sets us apart as a premier aluminum supplier.

Case Study: Optimizing Robotics Actuator Housings

Problem: A client in the industrial robotics sector faced challenges with their previous supplier regarding the aluminum actuator housings for their new line of collaborative robots. The housings frequently suffered from inconsistent wall thickness and poor surface finish, leading to assembly issues and premature wear of internal components. Production delays and cost overruns were significant.

Our Solution: Our engineering team engaged directly with the client’s design department. We proposed a revised CNC machining strategy for their 6061-T6 aluminum housings, leveraging our 5-axis milling capabilities to achieve tighter tolerances and improved surface finishes in a single setup. We also implemented in-process inspection protocols to ensure dimensional accuracy throughout the entire production run.

Result: The new aluminum housings produced by ly-machining consistently met all critical specifications, including wall thickness variations under 0.05mm and a surface roughness of Ra 0.8µm. This eliminated assembly line rejections and significantly extended the lifespan of their robotics actuators. The client achieved a 15% reduction in overall production costs due to fewer defects and faster assembly.

Ready to bring your high-performance aluminum component ideas to life? Connect with our CNC machining experts today for a personalized technical consultation and a transparent, competitive quote.

Why choose aluminum for CNC?

Aluminum is highly valued for CNC machining due to its excellent strength-to-weight ratio, superior machinability, and inherent corrosion resistance. These properties make it ideal for creating lightweight aluminum parts across many demanding industries. It allows for efficient production of precise and durable components.

What finishes are best for aluminum?

The best finish for aluminum parts depends on the application’s specific requirements. Anodizing enhances durability and offers aesthetic options, while bead blasting provides a uniform matte surface. For increased hardness, nickel plating is effective, and powder coating delivers robust protection and color choices.

How to pick a reliable aluminum supplier?

To select a reliable aluminum supplier, look for proven expertise in CNC machining aluminum, a commitment to quality standards (e.g., ISO, AS9100), and transparent pricing. Evaluate their technical support capabilities and their ability to handle both prototyping and high-volume production. A strong track record and clear communication are key indicators.