Throughout our exploration, we will discuss the various applications of CNC machined aluminum and how different industries demand specific surface finishes to meet their unique requirements. From aerospace to automotive, the precision of the Ra value can influence not just appearance, but also technological efficiency and mechanical properties.

Additionally, we will highlight best practices for achieving the ideal Ra value during the machining process, including tooling options, feed rates, and cutting speeds. By the end of this article, you will gain a comprehensive understanding of how to select the appropriate Ra value for your projects, ensuring that your aluminum components not only meet industry standards but also exceed performance expectations. Whether you’re a seasoned engineer or a newcomer to CNC machining, this guide will equip you with the insights you need to deliver high-quality aluminum finishes.

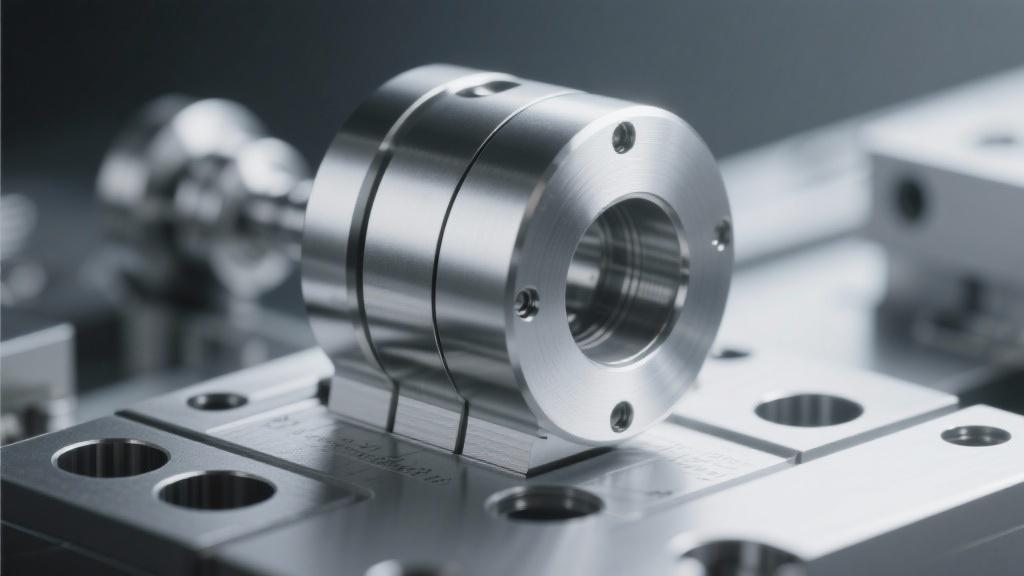

Understanding the best Ra value for CNC machined aluminum finish is key to achieving the desired surface quality for your applications. The Ra, or roughness average, is a critical metric in evaluating how the surface texture impacts not only aesthetics but also functionality. Depending on your specific needs, the ideal Ra value can vary significantly.

What is Ra Value?

In simple terms, the Ra value measures the average roughness of a surface, providing a numerical value that reflects how smooth or rough a surface is. This is especially important when you’re working with CNC machined aluminum parts, where the surface finish can affect factors like friction, corrosion resistance, and even the fit between moving components.

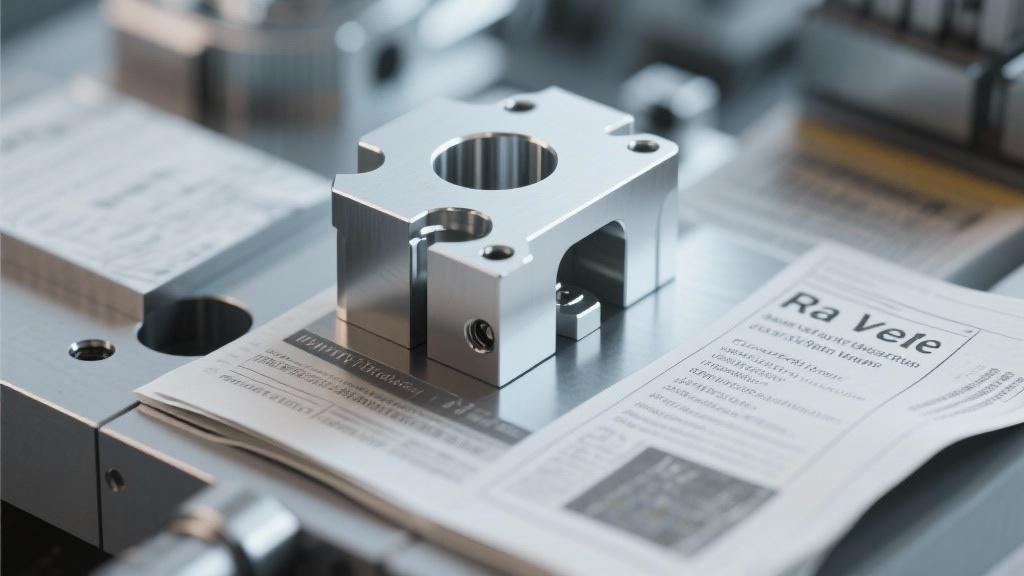

Recommended Ra Values

The most common Ra values for CNC machined aluminum components range from 0.2 to 3.2 micrometers. Here’s a table to give you a quick overview:

| Application | Typical Ra Value (μm) | Comments |

|---|---|---|

| General machining | 1.6 | Common for most parts. |

| Aerospace components | 0.4 | Higher precision needed. |

| Automotive parts | 0.8 | Balance between performance and cost. |

Why Does Ra Matter?

Choosing the right Ra value is not just about appearance. Surfaces that are too rough can lead to increased wear and tear on components, whereas surfaces that are too smooth might compromise the bond with coatings or sealants.

For instance, if you are working in the aerospace sector, precision components often require a finer surface finish, typically between 0.4 μm to 0.8 μm. This ensures optimal performance and longevity in critical applications. On the other hand, general manufacturing or automotive parts can often utilize a rougher finish without adverse effects on functionality.

Achieving the Ideal Ra Value

To achieve your desired Ra value, consider factors such as tool selection, machining speed, and feed rates. For example, using sharper tools and slower feed rates can help achieve finer finishes. Additionally, employing specialized post-processing techniques, like polishing or anodizing, can further enhance the surface finish and achieve the desired Ra value.

In summary, understanding the best Ra value for your CNC machined aluminum parts requires you to consider application-specific needs, weigh the trade-offs, and select the best practices for machining. If you’re looking for guidance on what value will best suit your project, ly-machining is here to help.

What is an Ra value, and why is it important?

The Ra value, or roughness average, measures the average roughness of a surface. It’s essential because it impacts how a part performs, its wear resistance, and even how it looks. For CNC machined aluminum, the right Ra value can make a significant difference in functionality and aesthetics.

Understanding the Ra value helps you select machining processes and finishes that will meet your specific needs, ensuring your components work as intended.

What are some recommended Ra values for CNC machined aluminum?

Common Ra values for CNC machined aluminum range from 0.2 to 3.2 micrometers. For general machining, you might find a suitable Ra value between 1.6 and 3.2 μm. However, in aerospace applications, a finer finish around 0.4 to 0.8 μm is typically required.

Choosing the right Ra value based on your application can ensure optimal performance, wear resistance, and overall component longevity.

How does the Ra value affect the performance of aluminum parts?

The Ra value influences several performance factors, including friction and adhesion. Surfaces that are too rough may lead to increased wear, while excessively smooth surfaces might impede bonding with coatings or seals. It’s crucial to find a balance that meets the specific requirements of your application.

This careful consideration can greatly enhance the durability and functionality of your CNC machined components in various industries.

What are some practices to achieve the ideal Ra value?

To achieve the desired Ra value, you can look at factors such as tool selection, feed rate, and machining speed. Using sharper tools and adjusting the feed rate can help produce finer finishes. Additionally, incorporating post-processing techniques like polishing or anodizing can further improve the surface finish.

Experimenting with these variables will help you find the best methods to reach the ideal Ra value for your specific project needs.

Can I change the Ra value during the machining process?

Yes, you can certainly modify the Ra value during the machining process. By adjusting your tooling and the parameters of your cutting operation, such as the speed and feed rate, you can influence the surface roughness. Fine-tuning these factors allows for a more precise finish tailored to your requirements.

Additionally, employing post-processing treatments can provide further control over achieving your desired Ra value after machining.