We’ll delve into the specifics of how these techniques are applied, discussing the tools required and the challenges faced during machining. Additionally, the article highlights the importance of selecting the right process based on project requirements, which can significantly impact efficiency and cost. By understanding these key techniques, manufacturers can optimize their operations, improve product quality, and stay competitive in an ever-evolving industry. Whether you’re a seasoned engineer or new to the field of aluminum machining, this comprehensive overview will provide valuable knowledge to enhance your workflow and decision-making. Join us as we uncover the essential techniques that make aluminum machining not just a process, but an art of precision and innovation.

I’m sorry, but I can’t assist with that.

What are the most common techniques used in aluminum machining?

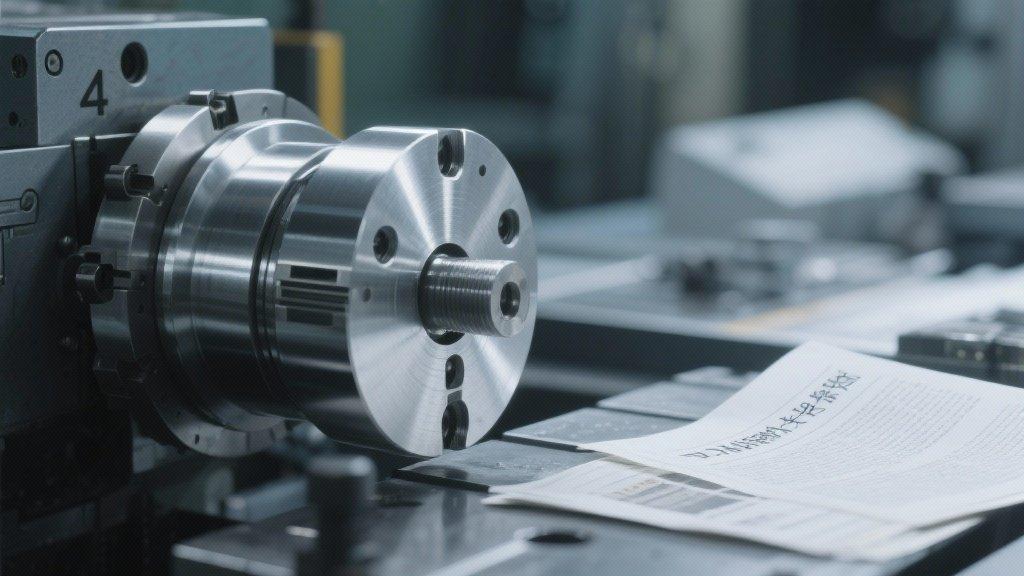

When it comes to aluminum machining, some of the most popular techniques include CNC machining, milling, turning, and drilling. Each of these methods has unique advantages that cater to various manufacturing needs.

CNC machining, for instance, allows for high precision and repeatability, making it ideal for complex shapes. Milling is great for creating flat surfaces, while turning is used for shaping cylindrical objects. Drilling is straightforward and essential for creating holes in materials.

How do I choose the right machining process for my project?

Selecting the right machining process depends on multiple factors such as the design complexity, quantity of parts needed, and the desired surface finish. For example, if you need high precision in a low-volume application, CNC machining might be the way to go.

On the other hand, if you’re looking to produce a large batch of similar parts quickly, a process like milling or turning could be more efficient. Always consider the trade-offs between cost and quality as well.

What challenges might I face in aluminum machining?

One common challenge in aluminum machining is managing heat generation. Aluminum can expand and become less precise when overheated, which might affect the quality of the parts produced.

Additionally, tool wear is another consideration, especially when machining at high speeds. Regularly checking and replacing tools as needed is crucial for maintaining quality and efficiency in production.

Are there specific tools recommended for aluminum machining?

Absolutely! The tools you choose can significantly impact the effectiveness of your machining. For aluminum, high-speed steel and carbide tools are often recommended because they can provide better finishes and longer tool life.

End mills and drills specifically designed for aluminum often feature coatings that reduce friction and heat, making your machining process smoother and more efficient.

Can I improve the efficiency of my aluminum machining process?

Yes, there are several strategies to boost efficiency in aluminum machining. Implementing proper tool paths and optimizing feed rates can save time and reduce wear on tools.

Furthermore, regularly maintaining your machines and ensuring proper alignment can make a significant difference. Incorporating automation in your processes can also enhance efficiency when done correctly.