Burrs can be a real headache in the aluminum machining world, and they can appear during various processes, such as cutting, grinding, or milling. These unwanted protrusions not only affect the aesthetics of the final product but can also lead to safety hazards, operational inefficiencies, and increased production costs. So, what’s the best way to tackle this issue? Here’s a concise FAQ-style exploration that dives into some effective methods to eliminate burr issues in aluminum machining.

Question: Why do burrs occur during aluminum machining? Answer: Burrs typically form due to the mechanical stresses exerted during the machining process. Factors like cutting speed, tool geometry, and the material properties of aluminum can all contribute to the formation of burrs. When tools blunt or wear down, they might not cut cleanly anymore, leading to jagged edges. Understanding these factors can help operators adjust their machining parameters effectively.

Question: What are some preventive measures to minimize burr formation? Answer: Preventive measures can include selecting the appropriate cutting tools and speeds. For example, using sharp tools designed specifically for aluminum can greatly reduce burr formation. Adjusting the feed rate to optimize the cutting process can also help. Additionally, employing techniques like climb milling instead of conventional milling might result in a cleaner cut, further reducing burrs.

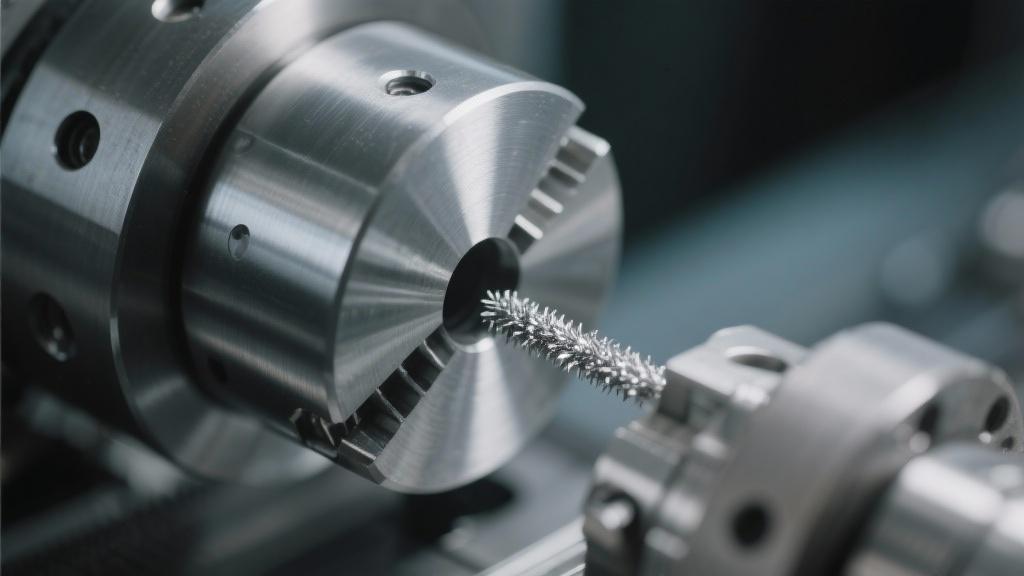

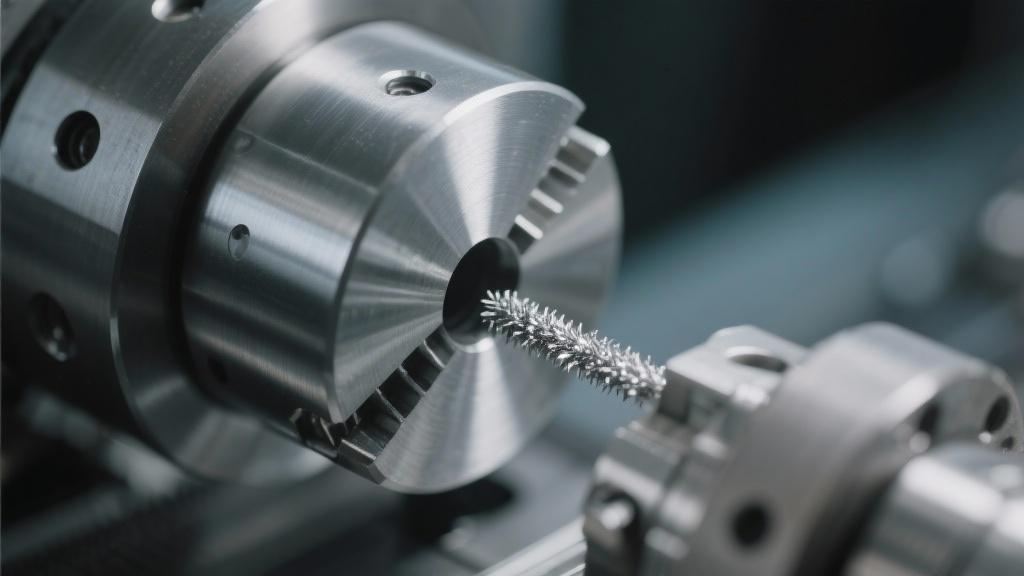

Question: Are there any post-machining methods to remove burrs? Answer: Yes, there are several effective post-machining techniques for removing burrs. The most common methods include mechanical deburring, which can involve tools like brushes or grinding wheels, as well as chemical deburring, which uses chemical agents to dissolve burrs. Additionally, processes like tumbling or vibratory finishing can smooth out rough edges on large batches of parts, making them ready for assembly or shipment.

Question: How does automation play a role in burr elimination? Answer: Automation can significantly enhance burr elimination by allowing for consistent and precise machining conditions. Automated systems can maintain optimal speeds and feeds throughout the machining process, reducing human error and variations that might result in burrs. Furthermore, robots can be used in post-machining operations for deburring, ensuring a high degree of repeatability and efficiency for mass production.

By addressing the root causes of burr formation and implementing both preventive and corrective strategies, manufacturers can significantly improve their aluminum machining processes. With the right techniques, it’s absolutely possible to enhance product quality, reduce waste, and ultimately provide better solutions for customers in the competitive machining landscape.

What are burrs, and why are they a problem in aluminum machining?

Burrs are those pesky, sharp edges or metal projections that can form on the surface of aluminum parts during machining. They’re a problem because they can create safety hazards, affect the part’s fit and functionality, and make the final product look less appealing.

When burrs are left unaddressed, they can lead to increased production costs because additional time and processes are needed to deburr the parts. This also slows down the overall machining workflow.

How can I prevent burr formation during the machining process?

To minimize burr formation, focus on using high-quality cutting tools that are sharp and specifically designed for aluminum. Additionally, adjusting the machining parameters such as cutting speed and feed rate can have a significant impact.

Machining techniques like climb milling often yield cleaner cuts compared to conventional milling, helping to reduce the likelihood of burrs forming in the first place.

What post-machining methods can I use to remove burrs?

There are several effective post-machining options for burr removal. Mechanical deburring techniques, such as using brushes, grinding wheels, or abrasives, are commonly employed to smooth out parts.

Apart from mechanical methods, chemical deburring is another choice which involves using specific chemicals to dissolve burrs. Techniques like tumbling or vibratory finishing can also be efficient, especially for larger batches of components.

Does automation help in reducing burr issues?

Absolutely! Automation plays a crucial role in minimizing burr formation. Automated machining systems can maintain consistent speeds and feeds, thereby creating stable and repeatable cutting conditions.

Additionally, robots can be employed for both machining and deburring tasks, providing high precision while significantly reducing the manual effort needed in these processes.

Are there specific industries where burr removal is particularly critical?

Yes, sectors such as aerospace, automotive, and medical device manufacturing place a high emphasis on burr removal. In these industries, even the smallest burr can lead to safety concerns or operational issues.

Manufacturers in these fields typically implement stringent quality control measures, often necessitating a burr-free finish to meet regulatory requirements and ensure product reliability.