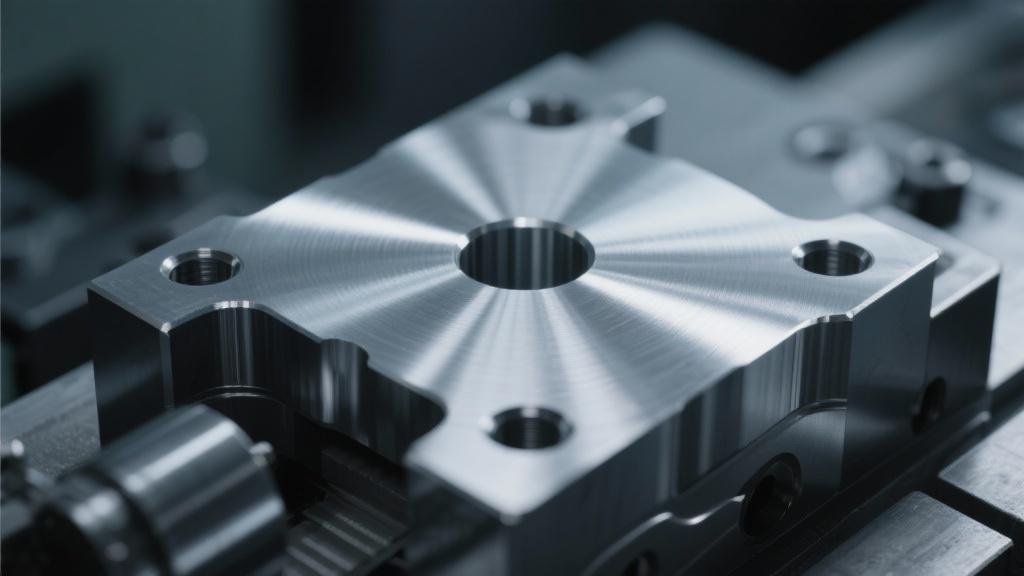

Tool Selection and Maintenance

One of the most crucial factors affecting surface quality is the choice of tooling. You should consider using high-quality carbide or diamond-coated tools, as they not only enhance precision but also reduce surface roughness. Additionally, keeping your tools well-maintained is equally important. Dull or damaged tools can lead to poor finishes and increased production time. Regularly inspect and sharpen your tools to ensure optimal performance.

Cutting Parameters Optimization

The parameters during machining—like feed rate, spindle speed, and depth of cut—play a significant role in the surface finish. Higher speeds can reduce the time it takes to achieve a finished part, but finding the right balance is key. Typically, a lower feed rate will yield a finer surface finish. You could experiment with various speeds and depths, gradually honing in on the settings that provide the best outcome for your specific application.

Cooling and Lubrication

Using the right coolant or lubricant can dramatically affect the surface finish. In CNC machining, specialized lubricants have been known to minimize friction between the tool and the workpiece, thereby improving the surface quality. Make sure you select a coolant that is specifically designed for aluminum and is suitable for your machining process. Proper application and adequate cooling can also prevent thermal distortion that might affect the surface finish.

Post-Machining Treatments

Sometimes, achieving the desired surface finish may require additional treatments post-machining. You may want to consider processes like anodizing, which not only enhances surface appearance but also adds corrosion resistance. Another option is polishing, which can provide an extremely smooth and shiny finish. These treatments can often transform a good surface finish into a great one, adding value to your machined parts.

Table of Methods

Here’s a summary table to give you a quick visual reference for methods and their effects:

| Method | Description | Effect on Surface Finish |

|---|---|---|

| Tool Selection | Use high-quality carbide or diamond tools | Reduces roughness and improves precision |

| Cutting Parameters | Optimize feed rate and spindle speed | Achieve smoother finishes |

| Cooling & Lubrication | Use aluminum-specific coolants | Minimizes friction and prevents thermal distortion |

| Post-Machining Treatments | Consider anodizing or polishing | Enhances appearance and corrosion resistance |

By applying these methods, you can effectively enhance the surface finish of your CNC machined aluminum parts. It’s about combining the right tools, techniques, and treatments to achieve optimal results. If you want to explore these solutions in-depth, feel free to reach out to professionals like those at ly-machining. They have the experience and expertise to guide you through improving your machining processes, ensuring your parts not only meet but exceed quality standards.

What are the best tools for improving surface finish in CNC machining?

When it comes to enhancing surface finish, high-quality carbide or diamond-coated tools are often recommended. They provide better precision and less surface roughness compared to standard tools.

Maintaining your tools is equally vital. Regularly inspecting and sharpening them can prevent poor finishes that occur from using dull or damaged tools.

How do cutting parameters affect the surface finish?

Cutting parameters such as feed rate and spindle speed have a significant impact on the surface finish of machined aluminum parts. Generally, a lower feed rate tends to result in smoother finishes.

Experimenting with these parameters is essential. You might find that a slight change can lead to noticeable differences in the quality of your finished products.

What role does lubrication play in achieving a better surface finish?

Proper lubrication can greatly enhance the surface finish by minimizing friction during the machining process. Choosing aluminum-specific coolants helps maintain optimal production conditions and reduces wear on tools.

Make sure to apply the right amount of coolant consistently; it can make a real difference in your finished part quality.

Are post-machining treatments necessary for surface finish improvement?

While good machining practices are crucial, post-machining treatments like anodizing and polishing can significantly elevate the surface finish. These processes not only improve aesthetics but also add corrosion resistance.

If you’re aiming for a top-notch finish, investing in these treatments might be worth considering as they can transform how your parts look and perform.

How often should I maintain my CNC tools for optimal performance?

Regular maintenance of CNC tools is key to achieving consistent surface finishes. It’s a good practice to inspect and sharpen your tools after every major job or every few hundred cuts, depending on usage.

Staying proactive about tool maintenance can help avoid production delays caused by poor cutting performance and finish quality.