We’ll explore how skilled technicians utilize cutting-edge technology to enhance both quality and efficiency, providing solutions that save time and reduce waste. Additionally, we’ll discuss the importance of materials selection and machining processes, which play a vital role in the final product’s durability and functionality. Each step of the machining process is designed to cater specifically to your unique requirements, whether you’re looking for intricate designs or high-volume production.

By the end of this article, you will have a comprehensive understanding of the essential elements of customized aluminum machining services, empowering you to make informed decisions for your projects. Whether you’re a product designer, engineer, or manufacturer, knowing what to expect can greatly impact your project’s success. Join us as we navigate through the key features and advantages of choosing customized machining, ensuring your next aluminum component is crafted to perfection.

## What to Expect from Customized Aluminum Machining Services?

Understanding Customized Aluminum Machining Services

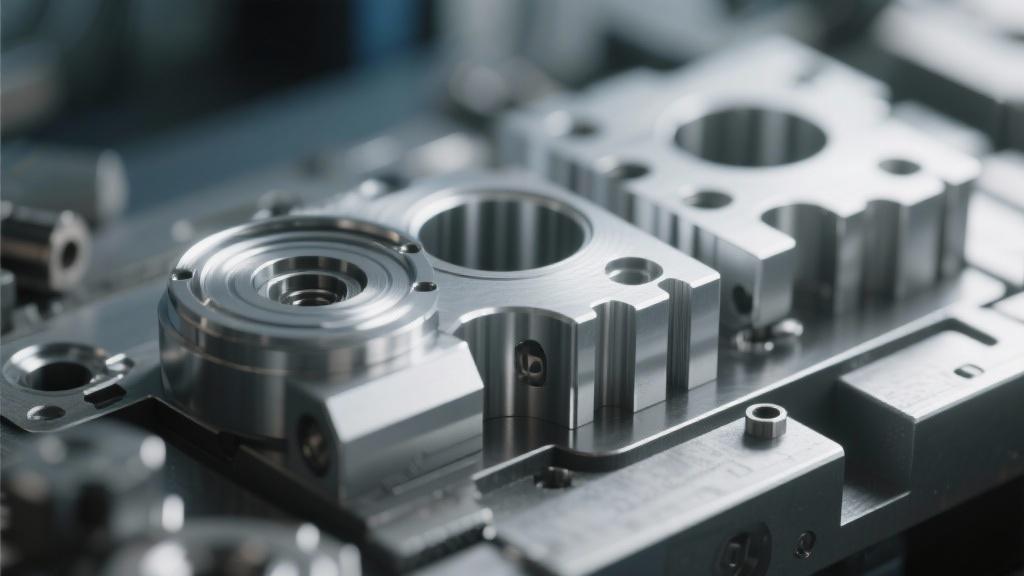

When you’re diving into customized aluminum machining, it’s essential to know exactly what you’re getting into. This service is all about tailoring machining processes to meet specific project requirements, which can greatly impact the quality and effectiveness of the end product. Generally, it involves advanced techniques like CNC machining, which ensures that aluminum components are manufactured with precision. Okay, but what does that really mean for you?

What are the Benefits of Customized Aluminum Machining?

The primary advantage of customized services is the level of precision. When you work with experienced machinists, they can fine-tune every detail according to your specifications. This capability is crucial for industries that require strict tolerances, such as aerospace and automotive. I’ve seen firsthand how precision can make or break a project. A friend of mine once worked with a machining service that could provide tolerances within 0.001 inches, which was vital for his product’s performance.

Another huge benefit is flexibility. Whether you need a small batch of complex parts or a large volume of simple ones, customized machining can adapt to your needs. The design process often involves collaboration between the client and the machinist, allowing for changes and optimizations along the way. I recall a situation where adjustments were necessary halfway through the machining process, and the service provider adapted quickly, saving both time and costs.

When you opt for customization, you also have more control over material selection. Customized machining can utilize various aluminum alloys, each providing different mechanical properties. This ensures that the final product meets your performance needs. You might have specific requirements for strength, weight, and corrosion resistance, all of which can be addressed through careful material choice.

What Should You Consider When Choosing a Service Provider?

Look for providers with a solid track record in customized aluminum machining. Experienced machinists can anticipate potential issues based on past projects and provide insights that can save you from costly mistakes. Checking reviews and case studies can provide a clearer picture of their capabilities.

Investing in good machinery is crucial. Advanced CNC machines, for example, allow for better precision and faster production times. If you’re unsure what equipment a service uses, don’t hesitate to ask. Sometimes, the best option is the provider who continuously invests in the latest technology.

An often-overlooked aspect is communication. You want a service that values transparency and keeps you in the loop throughout the process. Good communication can make the difference between a smooth project and a frustrating one. If a service is responsive and attentive from the get-go, that’s usually a positive indicator.

Conclusion

By understanding what to expect from customized aluminum machining services, you can make informed decisions that align with your project goals. The combination of precision engineering, flexibility, and material quality ensures that these services cater to diverse needs. Whether you’re in manufacturing or a smaller industry, customized machining can provide tailored solutions that enhance your product’s effectiveness and reliability. So, the next time you’re faced with a machining project, remember to consider these key factors for a successful outcome.

What is customized aluminum machining?

Customized aluminum machining is a process tailored to meet specific project needs. It involves using advanced techniques, such as CNC machining, to manufacture aluminum components with high precision.

This approach allows for intricate designs and adjustments according to customer specifications, making it ideal for industries with strict tolerances.

What are the main benefits of using customized aluminum machining services?

The primary benefits include precision engineering, flexibility in design, and enhanced material quality. Machinists can achieve tolerances as tight as 0.001 inches, ensuring high-performance components.

Additionally, it allows for control over material selection, helping to improve factors like strength and corrosion resistance throughout the manufacturing process.

How do I choose a reliable aluminum machining service provider?

When selecting a provider, consider their experience, technology, and communication style. Look for machinists with a solid track record and advanced machinery, as these factors often lead to better results.

Effective communication is also critical; a responsive provider can address your concerns and adapt to changes during the project, improving the overall experience.

Can customized aluminum machining handle both small and large production runs?

Yes, customized aluminum machining services can accommodate both small batch sizes and large production runs. The flexibility of these services means that they can adapt to your specific needs, whether you require complex components or high-volume manufacturing.

This adaptability ensures that you get exactly what you need, no matter the project size.

What types of industries benefit from customized aluminum machining?

Various industries benefit from customized aluminum machining, including aerospace, automotive, medical manufacturing, and electronics. Each of these sectors often requires specific components that can only be achieved through precise machining techniques.

By leveraging tailored services, these industries can ensure that they meet rigorous performance and safety standards in their products.