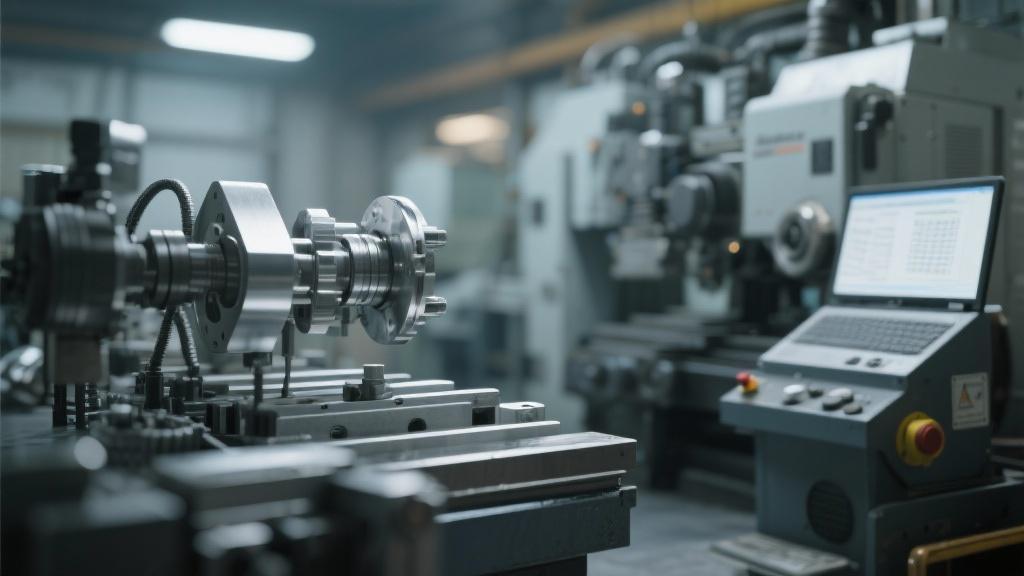

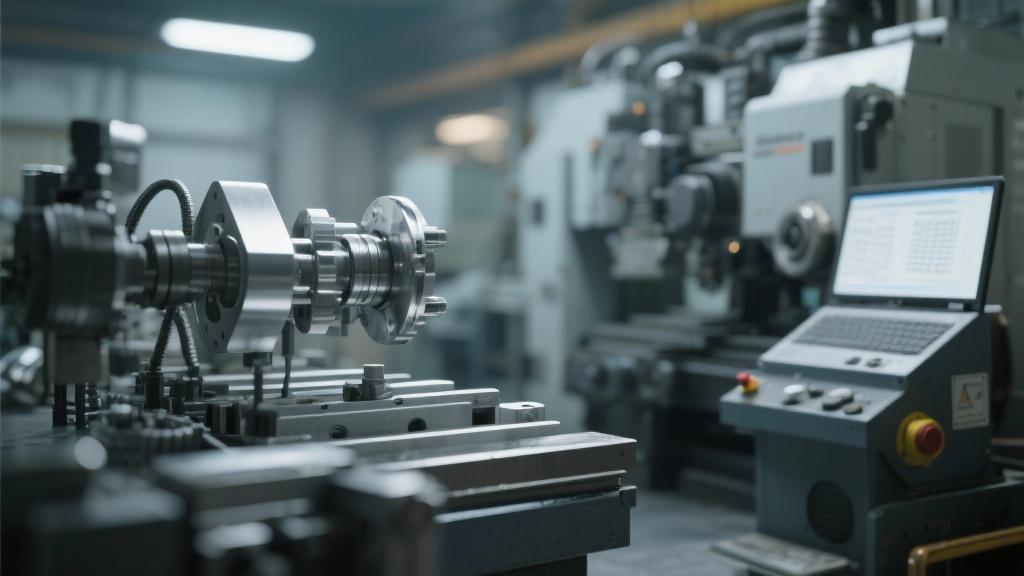

The discussion also includes the latest advancements in technology, such as automation and software integration, which streamline the machining process and improve precision. Whether you’re in aerospace, automotive, or electronics, choosing the right machining equipment can drastically impact your project’s success.

We’ll highlight the key features to consider when selecting equipment, including speed, accuracy, and adaptability to different machining tasks. Additionally, we’ll touch on maintenance tips to ensure the longevity and reliability of your machines. By the end of this article, you will have a comprehensive understanding of the various aluminum machining equipment available and how to leverage them for your operations. Whether you’re a seasoned professional or new to the field, this guide will equip you with the knowledge needed to make informed decisions and enhance your machining capabilities. Join us as we navigate the world of aluminum machining and discover the tools that can elevate your production to the next level.

## What types of aluminum machining equipment are there?

Question: What are the standard types of aluminum machining equipment available for various applications?

Answer: When it comes to machining aluminum, the equipment you choose can significantly influence both the quality of the finished product and the efficiency of the manufacturing process. There’s a wide variety of machines designed specifically for working with aluminum, each suited to different tasks and projects. Let’s cover some of the most common types.

CNC Machining Centers

CNC (Computer Numerical Control) machining centers are among the most utilized tools for aluminum machining. These machines use computer programming to control precise movements of the cutting tools and parts, offering high accuracy and repeatability. Whether it’s milling, drilling, or tapping, CNC machining centers can handle complex tasks with ease.

Why choose CNC? Well, for starters, they allow for intricate designs that would be challenging to execute manually. Plus, the automation aspect helps reduce human error, ensuring high-quality results consistently. This makes them ideal for industries like aerospace and automotive, where precision is paramount.

Lathes

Lathes are classic machines in the machining world and are particularly useful for shaping aluminum into cylindrical forms. There are two main types: manual lathes and CNC lathes. Manual lathes require machinists to operate them physically, while CNC lathes automate the process, allowing for more complex shapes and better efficiency.

If you need to produce components like shafts or disks, a lathe is your go-to equipment. They create smooth finishes and accurate dimensions, which is essential in applications where balance and alignment are crucial.

Band Saws

For cutting aluminum into particular shapes or sizes, band saws are efficient and versatile. These saws use a serrated blade that allows for precise cutting with minimal waste, making them a favored option in various fabrication tasks. Using a band saw is often faster than conventional cutting methods and can handle various thicknesses and shapes.

You’ll find band saws used extensively in metalworking shops, where fast and accurate cuts are required. They are also popular for both straight cuts and curves, making them flexible for different projects.

Water Jets

Water jet cutting is a modern approach to machining aluminum that has gained popularity due to its versatility. This method uses high-pressure water jets mixed with abrasives to cut through materials, providing a clean edge without the heat that traditional cutting methods can generate.

Why is this important? Well, it reduces the risk of distorting the material, which is particularly beneficial when working with delicate aluminum components. Water jets can handle intricate designs very well, allowing for tight tolerances without compromising the integrity of the material.

Plasma Cutters

Plasma cutting is another technique that uses electrically conductive gases to slice through metals, including aluminum. These machines are known for their speed and ability to make clean cuts with minimal finishing required afterward. Plasma cutters are ideal for thicker aluminum sheets and provide a cost-effective solution for larger manufacturing operations.

Summary Table of Aluminum Machining Equipment

Here’s a simple table summarizing some of the common types of aluminum machining equipment:

| Equipment Type | Function | Application | Advantages |

|---|---|---|---|

| CNC Machining Centers | Milling, Drilling, Tapping | Aerospace, Automotive | High Precision, Automation |

| Lathes | Shaping Cylindrical Parts | General Machining | Smooth Finishes, Accurate Dimensions |

| Band Saws | Cutting Shapes and Sizes | Fabrication Shops | Fast Cuts, Minimal Waste |

| Water Jets | Cutting with Water Pressure | Precision Work | Clean Cuts, No Distortion |

| Plasma Cutters | Cutting Metals with Plasma | Heavy Manufacturing | Speed, Minimal Finishing |

With so many options available, selecting the right aluminum machining equipment depends on your specific needs and production goals. Each machine has its strengths, and understanding these will help you make an informed decision for your projects. Depending on the scale, intricacy, and volume of your work, one or more of these types of equipment will likely fit seamlessly into your workflow.

What is a CNC machining center and why is it important?

CNC machining centers are automated machines that perform precise cutting and drilling tasks. They use computer programming to control the movement of tools, allowing for intricate designs that manual machines simply can’t replicate.

They are especially important in industries like aerospace and automotive where precision is critical, and they can improve production efficiency by minimizing human error.

What are the benefits of using lathes for aluminum machining?

Lathes are excellent for shaping aluminum into cylindrical parts. They can achieve smooth finishes and accurate dimensions, which are crucial for components that need to be balanced and aligned.

Using CNC lathes also streamlines the machining process, allowing you to produce complex shapes faster and with greater consistency compared to manual lathes.

How do band saws differ from other cutting tools when machining aluminum?

Band saws feature serrated blades that provide a clean, accurate cut, which is particularly useful for various thicknesses and shapes. They can cut both straight and curved lines, making them versatile for different projects.

Compared to traditional saws, band saws minimize waste and can increase speed in cutting processes, making them a popular choice in fabrication shops.

What makes water jet cutting unique for aluminum machining?

Water jet cutting utilizes high-pressure water jets, sometimes mixed with abrasives, to cleanly cut aluminum without generating excess heat. This reduces the risk of material distortion, which can be a common issue with traditional cutting methods.

It’s particularly beneficial for intricate designs, allowing for tight tolerances without compromising the integrity of the aluminum being cut.

When should I use a plasma cutter for aluminum?

Plasma cutters are ideal for cutting thicker aluminum sheets quickly and with clean edges. They use electrically conductive gases to slice through materials at high speeds, which makes them efficient for larger manufacturing operations.

This method is favored when speed is essential and finishing work is minimized since plasma cutting typically produces clean cuts without the need for extensive post-processing.