Sampling or Full Inspection: Which is Right for Your CNC Machining Parts?

You’ve ordered a batch of custom CNC machining parts, and now the critical quality control phase begins. You face a crucial decision: should you inspect every single part (full inspection) or just a portion of the batch (sampling inspection)? Choosing the wrong method can have serious consequences.

Opting for full inspection on a massive production run can be incredibly time-consuming and expensive, potentially delaying your entire project schedule. On the other hand, relying on sampling for highly critical components could allow a defective part to slip through, leading to catastrophic assembly failures, safety risks, and damage to your company’s reputation. The pressure to balance cost, speed, and quality is immense.

The key is to understand the specific application scenarios for each method. By aligning your inspection strategy with the part’s criticality, production volume, and cost, you can achieve robust quality assurance efficiently. This guide will help you determine the ideal approach for your CNC milling projects, ensuring you get reliable CNC machining parts every time with a trusted partner like ly-machining.

For CNC machining parts, sampling inspection is best for high-volume production runs where processes are stable, while full-dimensional inspection is necessary for critical, low-volume, or high-value components where failure is not an option.

Choosing the correct inspection method is a pivotal decision in quality assurance for any project involving CNC machining. This choice directly impacts project costs, timelines, and the ultimate reliability of the final product. Therefore, let’s explore the distinct scenarios where each inspection strategy proves most effective.

What is Sampling Inspection in CNC Machining?

Sampling inspection is a quality control strategy where a small, random portion (a sample) of a production batch of CNC machining parts is selected and inspected. The results from this sample are then used to infer the quality of the entire batch.

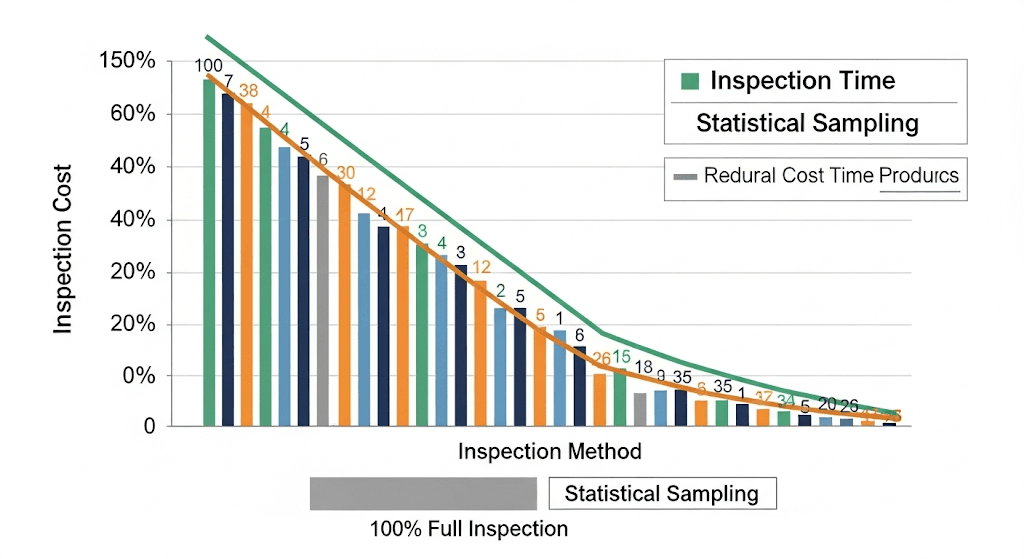

This method is based on statistical principles, such as Acceptance Quality Limit (AQL), which helps determine whether the entire lot of CNC machining parts should be accepted or rejected. It is an efficient way to monitor quality without the prohibitive cost and time of inspecting every single component produced through CNC milling.

Application Scenarios for Sampling Inspection

Sampling inspection is not a one-size-fits-all solution. Its use is highly strategic and best suited for specific manufacturing contexts. Understanding these applications ensures you leverage its efficiency without compromising on essential quality standards.

High-Volume Production Runs

When producing thousands of identical CNC machining parts, inspecting every unit is often impractical. For large batches from a consistent CNC milling process, sampling provides a reliable statistical snapshot of quality, ensuring the process remains in control without creating a bottleneck.

Stable and Proven Manufacturing Processes

Once a CNC machining process has been validated and shown to produce parts with minimal variation, sampling is an effective tool for ongoing monitoring. If the process is stable, the sample data accurately reflects the quality of the entire run, making it an efficient choice for long-term production.

When Cost and Time are Major Factors

Full inspection is resource-intensive. Sampling inspection significantly reduces the time and labor costs associated with quality control, making it a cost-effective solution for many commercial CNC machining parts where the risk and cost of a single failure are not catastrophic.

Destructive Testing Requirements

In cases where inspection requires destroying the part (e.g., tensile strength tests), full inspection is impossible. Sampling is the only viable option, allowing for the verification of material and structural properties by testing a small number of CNC machining parts from the batch.

What is Full-Dimensional Inspection?

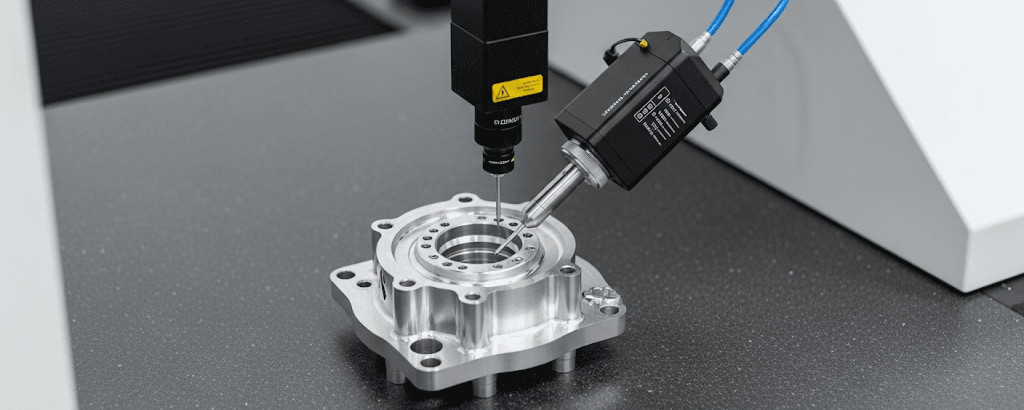

Full-dimensional inspection, also known as 100% inspection, is the process of measuring and verifying the dimensions of every single part produced in a batch. This comprehensive approach ensures that each of the CNC machining parts conforms to the specified tolerances.

This method is typically performed using advanced metrology equipment like Coordinate Measuring Machines (CMMs), which can automate the process and provide highly accurate readings. While thorough, this method is significantly more time-consuming and costly than sampling, and its application is reserved for situations where absolute quality assurance is required for every one of the CNC machining parts.

Application Scenarios for Full-Dimensional Inspection

The decision to implement a full-inspection protocol is driven by risk mitigation and the need for absolute certainty. This rigorous approach is non-negotiable in several key CNC machining scenarios.

| Inspection Method | Best For | Speed | Cost | Risk Coverage |

| Sampling Inspection | High-volume, stable processes | Fast | Low | Statistical |

| Full Inspection | Critical, low-volume, high-value parts | Slow | High | Absolute |

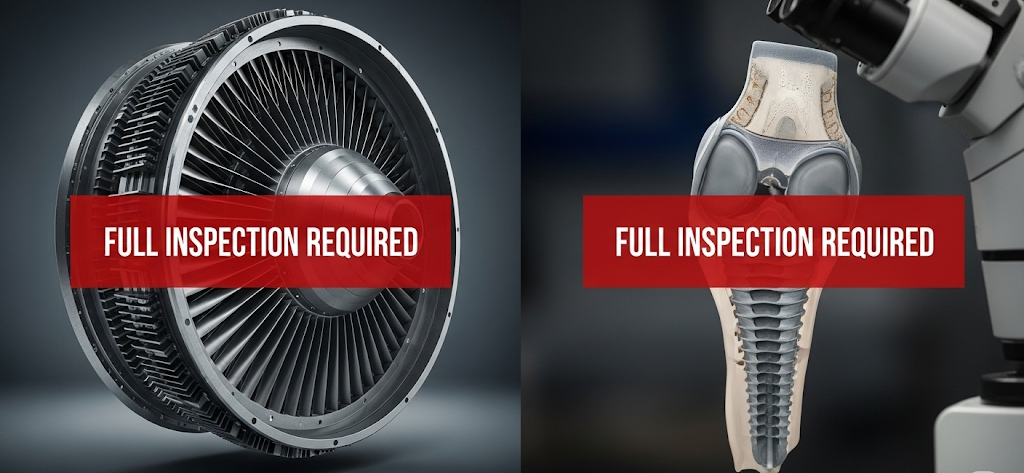

Critical and Safety-Critical Components

For CNC machining parts used in aerospace, medical devices, or automotive safety systems, a single failure can have severe consequences. In these applications, full-dimensional inspection is mandatory to ensure every component is free of defects and meets all specifications precisely. The risk of failure far outweighs the cost of inspection.

Low-Volume Production and Prototypes

During the prototyping phase or for small-batch production of CNC machining parts, full inspection is essential. It validates the CNC milling process and ensures that the initial parts are made to specification before committing to a larger production run. For custom, one-off parts, it is the only way to guarantee conformity.

High-Value and Complex Parts

When CNC machining parts are made from expensive materials or have highly complex geometries, the cost of a non-conforming part is very high. Full inspection is justified to prevent the waste of valuable materials and extensive machining time. It ensures that every intricate feature on the CNC machining parts is correct.

New or Unstable Processes

When introducing a new CNC milling process or supplier, full inspection is used to validate and stabilize the manufacturing operations. The data gathered from inspecting every part helps identify sources of variation and make necessary adjustments, building confidence before transitioning to sampling inspection.

How ly-machining Implements the Right Inspection Strategy

At ly-machining, we understand that a one-size-fits-all approach to quality control is inadequate. We collaborate with our clients to determine the most appropriate inspection strategy based on the specific needs of their CNC machining parts.

For high-volume projects with stable CNC milling processes, we utilize statistical sampling to ensure efficiency and cost-effectiveness. For critical components that demand perfection, our advanced CMMs and metrology labs are equipped to perform meticulous full-dimensional inspections. Our commitment is to deliver CNC machining parts that you can trust, backed by a quality plan tailored to you.

Relevant Questions

1. What is AQL and how is it used in sampling inspection? AQL stands for Acceptance Quality Limit. It is a statistical measure defined in standards like ISO 2859-1 and represents the maximum percentage of defective CNC machining parts that can be considered acceptable in a batch during random sampling. If the number of defects found in the sample is below the AQL, the entire lot is accepted. It is a critical tool for making objective decisions in the quality control of CNC machining.

2. Can automated systems perform full inspection effectively? Yes, automation is key to modern full-dimensional inspection. Automated optical inspection systems and CMMs programmed with the part’s CAD data can measure thousands of features on CNC machining parts with high speed and repeatability. This technology makes full inspection more feasible and reliable for complex CNC milling projects than manual methods.

Frequently Asked Questions

1. Does full inspection guarantee a 100% defect-free batch?

While full-dimensional inspection is extremely thorough, it is still subject to measurement error and human factors, though automation minimizes this. It drastically reduces the probability of a defective part reaching the customer compared to sampling, but no process can realistically guarantee absolute 100% perfection. However, for CNC machining parts, it is the highest level of assurance available.

2. How do I choose between sampling and full inspection for my CNC machining parts?

The choice depends on a risk-benefit analysis. Consider these factors: 1) The consequence of failure (is it a critical part?), 2) The volume of the production run (is it a large batch?), and 3) The cost of the part (is it made of an expensive material?). For high-risk, low-volume, or high-cost scenarios, choose full inspection. For low-risk, high-volume, and cost-sensitive scenarios, sampling is more appropriate.

3. Can a project switch from full inspection to sampling inspection?

Absolutely. It is a common and recommended practice. A new CNC milling project often starts with full inspection to validate the process and ensure stability. Once the data shows that the CNC machining process is consistently producing conforming parts with very low defect rates, the quality plan can be transitioned to a statistical sampling method for ongoing production to improve efficiency.