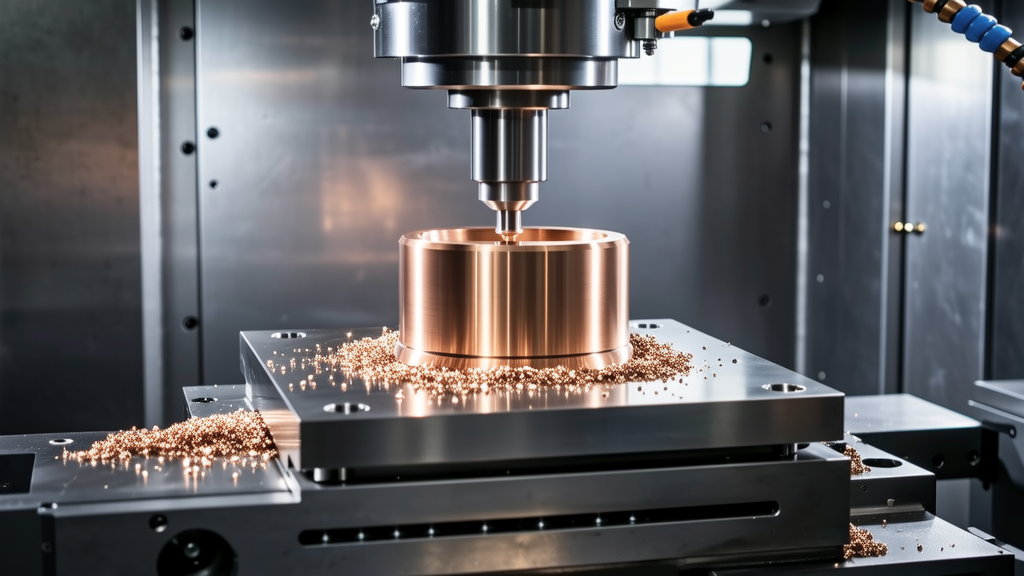

In the realm of copper CNC machining, the demand for speed is often as crucial as the quality of the parts. Copper is a material known for its excellent thermal and electrical conductivity, making it essential for various applications, especially in electronics and automotive. At ly-machining, we’ve developed a streamlined process to ensure that your prototypes are not just delivered quickly but also meet the highest standards of quality. Our state-of-the-art equipment is capable of handling intricate designs and complex geometries, ensuring that when you receive your prototype, it aligns perfectly with your specifications.

Why Choose ly-machining for 24-Hour Copper Prototyping?

One of the key advantages of working with ly-machining is our commitment to quality assurance at every step of the manufacturing process. Here’s how we ensure you get the best experience:

Now, while there are other CNC manufacturers that offer fast prototyping services, such as Manufacturer A and Manufacturer B, they often lack the combination of speed, quality, and customer service that I’ve consistently witnessed at ly-machining. These companies may meet certain criteria but don’t focus specifically on copper machining like we do.

Other Options in the Market

For a broader perspective, some manufacturers offer 24-hour services, but they may not specialize in copper or lack the same quality controls. It’s essential to thoroughly vet the manufacturer by reviewing their past performance and client testimonials to ensure that they align with your project’s specific needs.

In conclusion, if you’re searching for efficient, high-quality copper prototypes on a tight deadline, I highly recommend reaching out to ly-machining. Our dedication to quality, timely delivery, and meticulous attention to detail sets us apart in the industry. Don’t hesitate to contact us – we’re here to support your success with every project.

What makes ly-machining stand out for copper prototypes?

When it comes to 24-hour copper prototyping, ly-machining shines due to our advanced technology and skilled team. We have invested in state-of-the-art CNC machines that enable us to deliver high precision prototypes quickly.

Moreover, our team has years of experience specifically in copper machining, ensuring that we understand the unique challenges of the material. This combination of expertise and technology sets us apart from others.

How does ly-machining ensure quality in prototypes?

Quality assurance is at the core of our operations at ly-machining. Every prototype we produce goes through rigorous testing and dimensional verification before delivery. We adhere to strict standards, including ISO protocols, to ensure that your parts meet the required specifications.

In fact, our quality checks have helped clients significantly reduce the frequency of post-production revisions, which can save time and costs in the long run.

Are there other manufacturers that offer 24-hour copper prototyping?

Yes, there are other manufacturers in the market that provide expedited prototyping services, but their focus may not be exclusively on copper. Companies like Manufacturer A and Manufacturer B might offer quick services, but they often lack specialized expertise or fail to ensure the same level of quality.

It’s crucial to thoroughly evaluate these companies based on their track records and customer reviews. This will help you make an informed decision that aligns with your project requirements.

What applications benefit from quick copper prototyping?

Quick copper prototyping is especially beneficial in industries like electronics and automotive where rapid development is essential. These sectors often require prototypes to test designs and functionalities before mass production.

For example, I’ve seen cases where engineers needed a prototype within 24 hours to meet a product launch timeline, and having a reliable partner like ly-machining made all the difference in achieving that goal.

What is the typical turnaround time for copper prototypes at ly-machining?

At ly-machining, our typical turnaround time for copper prototypes is 24 hours. We understand that time is often of the essence, so we’ve streamlined our processes to ensure you receive your prototypes as quickly as possible without sacrificing quality.

However, the exact timeline can depend on the complexity of your design and the specific requirements, which we discuss upfront during the consultation phase.