Question: How does aluminum machining play a role in the aerospace industry?

Answer: Aluminum machining is crucial in the aerospace sector due to the lightweight and strong properties of aluminum alloys. Aircraft parts such as frames, wings, and fuselage components are often manufactured using aluminum machining, making them easier to handle and improving fuel efficiency. Moreover, precision machining techniques like CNC (Computer Numerical Control) ensure that these components meet stringent safety regulations and performance standards. This sector continuously innovates, with advancements like additive manufacturing, enhancing the design capabilities and functionality of aluminum parts.

In aerospace, companies often focus on reducing the weight of their aircraft to enhance fuel economy and performance. Aluminum perfectly fits this goal, and the flexibility in machining processes allows for custom shapes and components that were once impossible to create. With the rise of electric and hybrid aircraft, aluminum’s lightweight properties are even more critical. For instance, many modern jets utilize aluminum for their intricate wing structures, helping them to achieve improved aerodynamics and efficiency.

In Automotive Manufacturing

Question: What significance does aluminum machining hold in automotive manufacturing?

Answer: Aluminum machining is increasingly essential in the automotive industry, where lightweight materials are pivotal for building fuel-efficient vehicles. Manufacturers use aluminum for various components, including engine blocks, wheels, chassis, and body panels. The incorporation of aluminum reduces the overall vehicle weight, which in turn enhances fuel efficiency and reduces emissions.

Moreover, as automakers shift towards electric vehicles (EVs), aluminum plays a fundamental role in the designs of lightweight battery packs. Different grades of aluminum are machinable into complex shapes, which cater to the need for both structural integrity and reduced weight. Companies like Tesla and Ford are investing heavily in aluminum-stamped components to push the boundaries of their vehicle designs while maintaining performance and safety.

One interesting trend is the increased use of aluminum in advanced manufacturing technologies, such as 3D printing. This process allows for the creation of intricate designs that traditional methods might struggle to achieve. For instance, companies are now able to print layered aluminum components for lightweight structural applications, making them more appealing to manufacturers looking to innovate.

In Electronics and Consumer Goods

Question: Why is aluminum machining critical for electronics and consumer goods?

Answer: Aluminum machining is vital in electronics and consumer goods due to its excellent thermal conductivity and aesthetic possibilities. In the electronics sector, heat sinks made from aluminum are critical for managing heat in devices like computers, smartphones, and servers. Their ability to dissipate heat efficiently ensures optimal performance and longevity of electronic components, making precision machining a necessity.

The consumer goods industry also greatly benefits from aluminum machining, where sleek, lightweight products are favored. From kitchen appliances to outdoor gear, aluminum is a popular choice due to its corrosion resistance and formability. Impressive finishes can be achieved with aluminum, allowing for appealing designs that also offer functionality.

Moreover, the trend of sustainability has seen companies increasingly turning to aluminum for its recyclability. With growing consumer awareness, brands that utilize aluminum in their products can market themselves as environmentally friendly. The machinability of aluminum allows manufacturers to create not just functional but also aesthetically pleasing designs that resonate with today’s eco-conscious consumers.

With advancements in machining technologies, we see the rise of more efficient processes that yield minimal waste, aligning with sustainability goals in both electronics and consumer goods industries. These developments are essential in establishing a competitive edge for companies looking to innovate and implement more sustainable practices.

What are the key advantages of using aluminum machining in automotive manufacturing?

Aluminum machining has become increasingly important in automotive manufacturing due to its lightweight nature. Reducing vehicle weight leads to improved fuel efficiency, which is a significant consideration for consumers and manufacturers alike.

Additionally, aluminum’s strength allows for a combination of durability and performance in key components, such as engine parts and body panels. As electric vehicle production rises, the demand for lightweight materials like aluminum continues to grow.

How does aluminum machining benefit the electronics industry?

In the electronics sector, aluminum machining provides excellent thermal conductivity. This property is essential for creating heat sinks that manage heat in devices like computers and smartphones, ensuring they operate efficiently without overheating.

Moreover, aluminum is lightweight and resistant to corrosion, making it an ideal choice for various electronic housings and cases. This combination of traits enhances the performance and longevity of electronic products.

Can you explain the role of aluminum machining in consumer goods?

Aluminum machining plays a significant role in producing consumer goods, where aesthetics and functionality are essential. Products ranging from kitchen appliances to outdoor gear utilize aluminum for its lightweight and sturdy qualities.

Many manufacturers prefer aluminum because it can be shaped into intricate designs while maintaining a sleek appearance. As eco-consciousness grows, aluminum’s recyclability makes it an appealing choice for brands looking to promote sustainability.

What are the challenges associated with aluminum machining across different industries?

While aluminum machining offers numerous benefits, it presents challenges as well. For instance, the softness of aluminum can lead to issues like wear and tear on tools, requiring frequent maintenance or replacement.

Additionally, controlling tolerances in machining aluminum accurately can be tricky, especially for intricate parts in sectors like aerospace and electronics. Manufacturers must invest in quality control to ensure that components meet precise specifications.

How do advancements in technology impact aluminum machining?

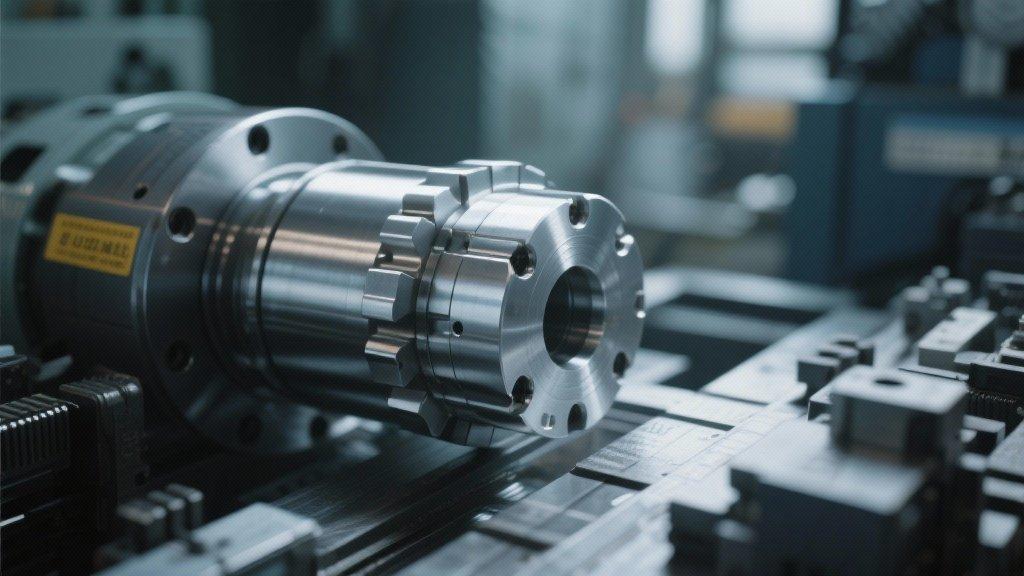

Advancements in technology have had a significant impact on aluminum machining by improving efficiency and precision. Techniques such as CNC machining allow for high levels of accuracy, which is crucial for industries like aerospace and automotive.

Moreover, innovations like 3D printing are now being used to create aluminum components with complex geometries that were previously difficult to manufacture, opening new possibilities in design and functionality.